Core-shell structure high-strength anti-seismic unbaked ceramsite and preparation method and application thereof

A core-shell structure, earthquake-resistant technology, applied in the field of building materials, can solve the problems of affecting the mechanical properties of ceramsite, low cylinder compressive strength, lack of toughness, etc., to achieve high social and economic value, heat-resistant geometric dimensional stability, Reduce the effect of excessive deformation and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

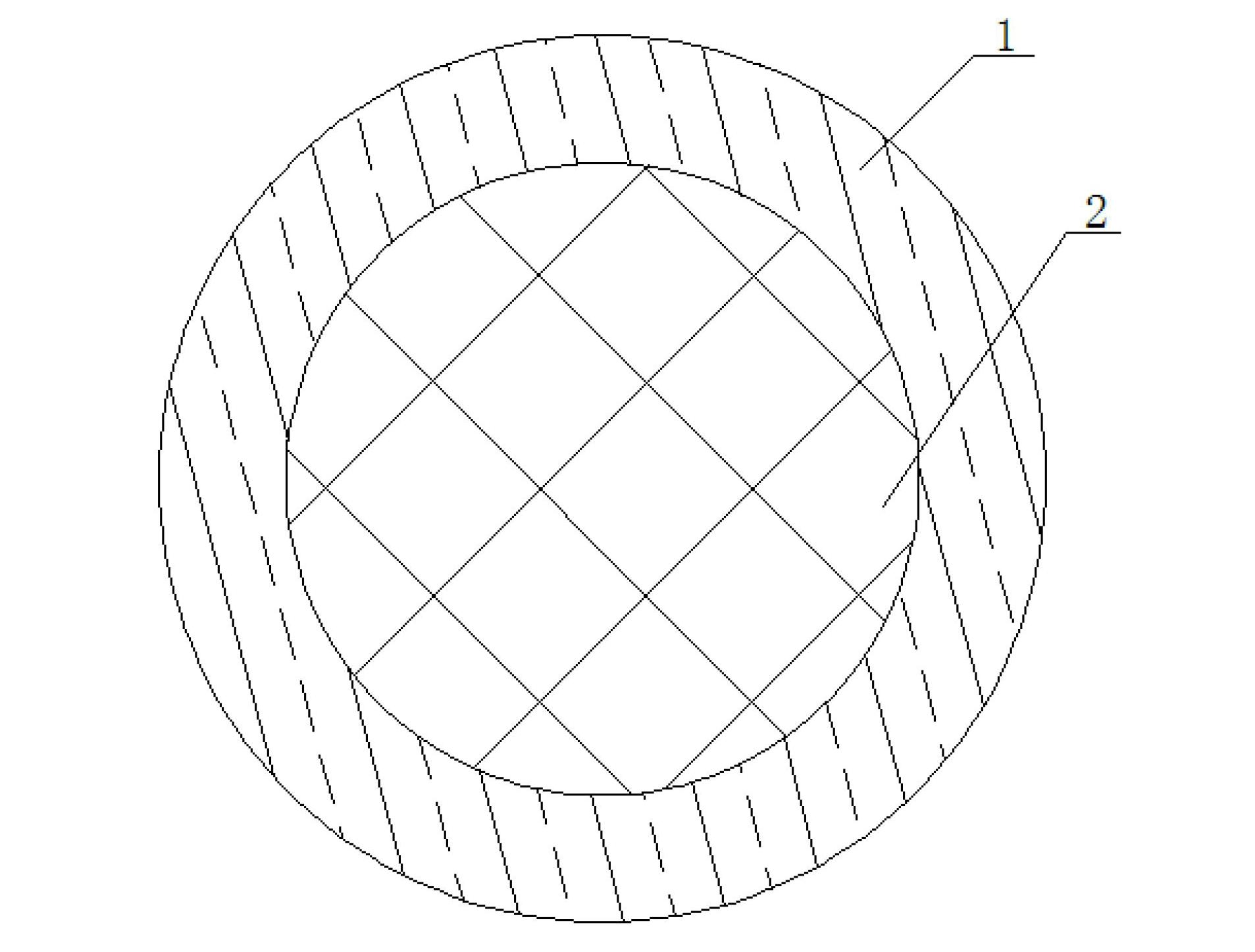

[0046] A core-shell structure high-strength anti-shock type non-fired ceramsite, including a core 2 and a shell 1 wrapped outside the core, such as figure 1 Shown, its composition is according to the following components by weight percentage:

[0047] Construction solid waste: 77.73%

[0048] Foam balls (1mm in diameter): 0.43%

[0049] 525# Ordinary Portland cement: 16.95%

[0050] Silica powder: 3.39%

[0051] Sodium carboxymethyl cellulose: 1.50%

[0052] Among them, the foam ball is used as the inner core 2, and the remaining components are used as the outer shell 1.

[0053] Its preparation method is:

[0054] a. Process construction solid waste into granules, 525# ordinary Portland cement, and silicon micropowder according to the above weight ratio as the formula, mix with a strong mixer, and then enter the barrel mill to mix and grind until the sieve through 0.045mm is less than 30%, After sieving through 0.080mm, less than 5% of the powder remains, and the resulti...

Embodiment 2

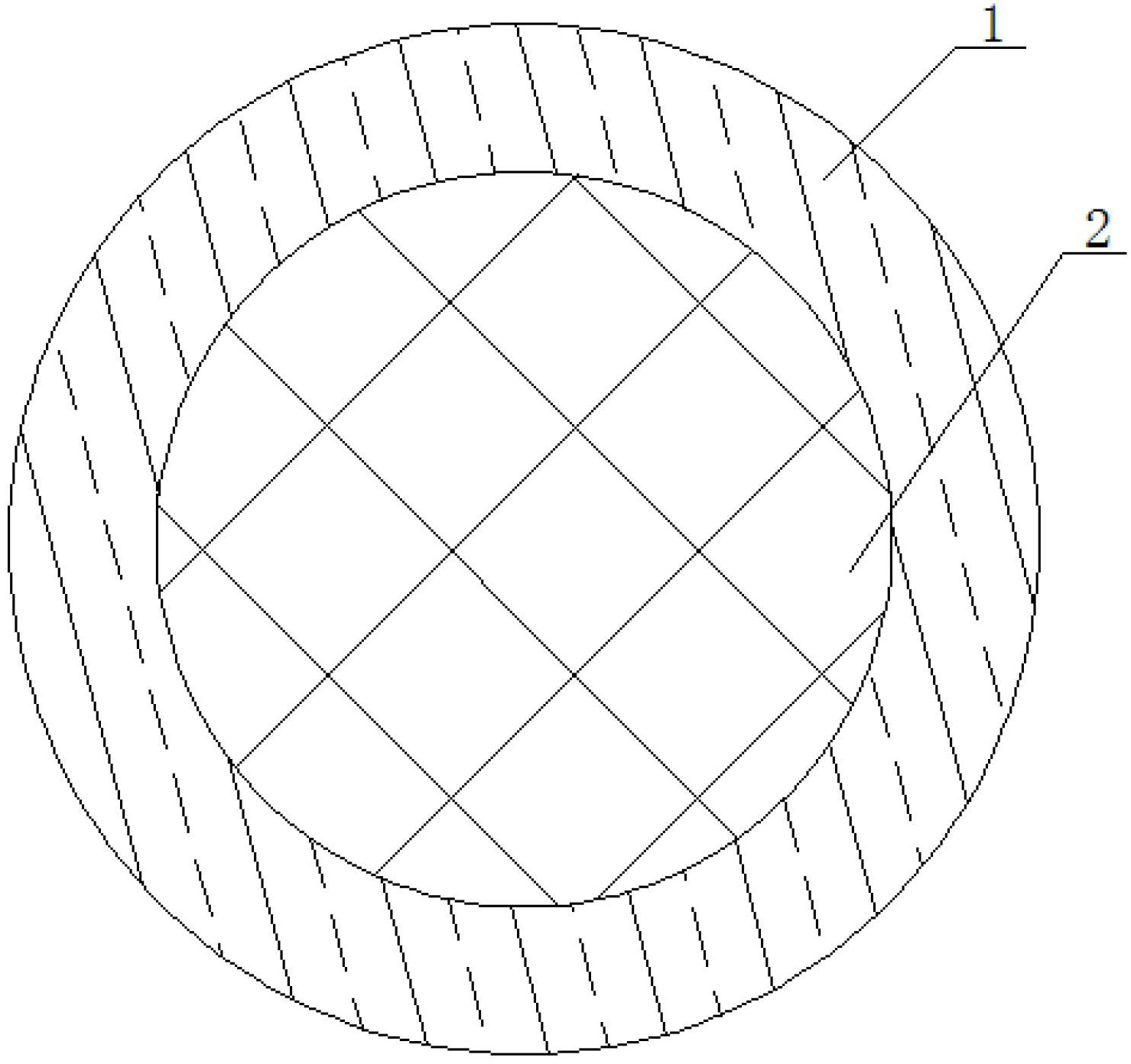

[0060] A core-shell structure high-strength shock-resistant unfired ceramsite, comprising an inner core 2 and a shell 1 wrapped outside the inner core, which is composed of components according to the following weight percentages:

[0061] Construction solid waste: 81.73%

[0062] Foam balls (2.5mm in diameter): 0.33%

[0063] 525# Ordinary Portland cement: 13.65%

[0064] Silica powder: 2.99%

[0065] Sodium carboxymethyl cellulose: sodium alginate (mass ratio 1:1) 1.30%

[0066] Among them, the foam ball is used as the inner core 2, and the remaining components are used as the outer shell 1.

[0067] The preparation method is the same as that of Example 1 except that step b is operated for 3 minutes and step c is operated for 5 minutes, and the thickness of the final ceramsite shell 1 is 1.5 mm.

Embodiment 3

[0069] A core-shell structure high-strength shock-resistant unfired ceramsite, comprising an inner core 2 and a shell 1 wrapped outside the inner core, which is composed of components according to the following weight percentages:

[0070] Construction solid waste: 83.13%

[0071] Foam balls (5mm in diameter): 0.23%

[0072] 525# Ordinary Portland cement: 12.95%

[0073] Silica powder: 2.59%

[0074] Sodium carboxymethyl cellulose: sodium alginate: polyvinyl alcohol (mass ratio 1:1:1) 1.10%

[0075] Among them, the foam ball is used as the inner core 2, and the remaining components are used as the outer shell 1.

[0076] Its preparation method is the same as that of Example 1, and the final ceramsite finished shell 1 has a thickness of 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com