Edible fishskin collagen antibiosis membrane and preparing method thereof

A technology of fish skin collagen and antibacterial film, applied in the direction of climate sustainability, sustainable manufacturing/processing, flexible coverings, etc., can solve the problems of antibacterial performance, failure to achieve antibacterial activity, etc., and achieve good antibacterial activity , inhibition of growth, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

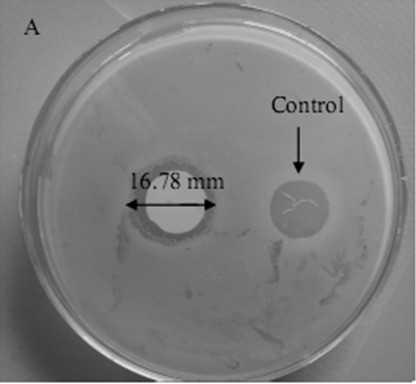

[0018] Weigh 3 g collagen and dissolve it with 30 ml distilled water at 45°C to make collagen aqueous solution; weigh 1 g chitosan and dissolve it with 30 ml 1.5% (v / v) acetic acid solution at 60°C to make chitosan Sugar solution; ultrasonically dissolve 4 ml of oregano essential oil in 40 ml of distilled water containing 0.25 g of soybean lecithin to make oregano oil solution, then mix the three solutions, add 1.0 g of glycerin as a plasticizer, stir well, Let stand for 30 minutes to degas, and keep warm at 45°C. Pipette 6 ml of casting solution each time and spread it on a plexiglass frame of 120 mm×80 mm×2 mm to form a film. The film-forming temperature is 22°C and the film-forming time is 24 h. The collagen antibacterial film can be obtained. The antibacterial activity of the membrane was measured by the filter paper method, and the membrane was cut into a circle of 12 mm to investigate the antibacterial effect of the antibacterial membrane on Escherichia coli and Staphyl...

Embodiment 2

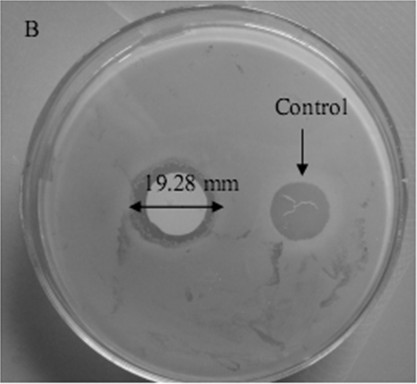

[0020] Weigh 1 g of collagen and dissolve it with 30 ml of distilled water at 45°C to make a collagen aqueous solution; weigh 3 g of chitosan and dissolve it with 30 ml of 1.5% (v / v) acetic acid solution at 60°C to make chitosan Sugar solution; ultrasonically dissolve 5 ml of clove essential oil in 40 ml of distilled water containing 0.25 g of soybean lecithin to make oregano oil solution, then mix the three solutions, add 1.6 g of glycerin as a plasticizer, stir evenly, and statically Set for 30 min to degas and keep warm at 45°C. Pipette 6 ml of the casting solution each time and spread it on a plexiglass frame of 120 mm×80 mm×2 mm to form a film. The film-forming temperature is 4°C and the film-forming time is 4 h. The collagen antibacterial film can be obtained. The antibacterial activity of the membrane was measured by the filter paper method, and the membrane was cut into a circle of 12 mm to investigate the antibacterial effect of the antibacterial membrane on Escheric...

Embodiment 3

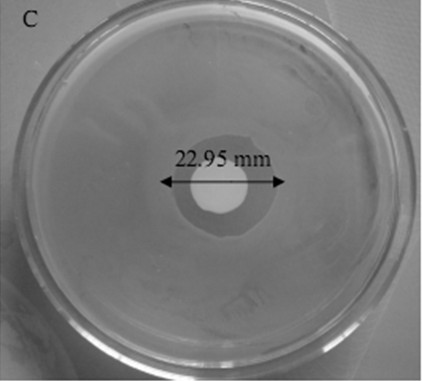

[0022] Weighed 4 g of collagen and dissolved it with 30 ml of distilled water at 45 °C to make a collagen aqueous solution; ultrasonically dissolved 3 ml of cinnamon essential oil in 40 ml of distilled water containing 0.25 g of soybean lecithin to make an oregano oil solution, and then The three solutions were mixed, 0.4 g of glycerin was added as a plasticizer, stirred evenly, left to stand for 30 min to degas, and kept at 45°C. Pipette 6 ml of the casting solution each time and spread it on a plexiglass frame of 120 mm×80 mm×2 mm to form a film. The film-forming temperature is 30°C and the film-forming time is 24 h. The collagen antibacterial film can be obtained. The thickness, mechanical properties, elongation at break, light transmittance at 600 nm and water vapor transmission rate of the prepared antibacterial film were measured, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com