Indoor water-based ultrathin steel-structure fireproof coating and preparation method thereof

A fire retardant coating, ultra-thin technology, applied in the direction of fire retardant coatings, coatings, etc., can solve problems such as harming the health of construction workers, reducing the fire protection effect of fire retardant coatings, human and environmental hazards, etc., to avoid the decline of fire performance and resist external The impact of flame, the effect of long flame resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

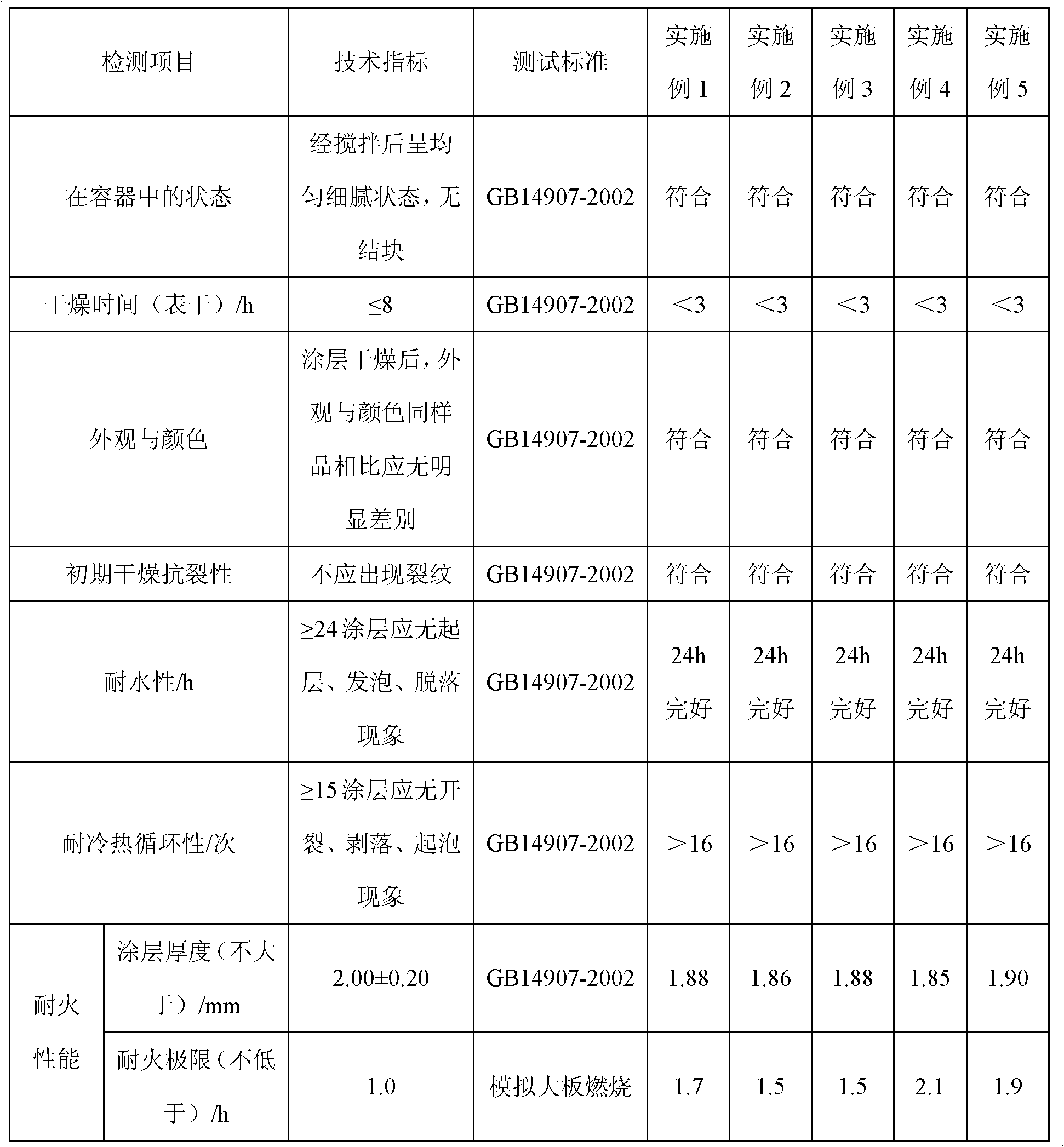

Examples

Embodiment 1

[0030] Under the rotating speed of 400r / min, in terms of mass parts, add 17 parts of tap water in the formula, 4 parts of antifreeze agent (propylene glycol, Dow Chemical), 0.2 part of anticorrosion and antifungal agent (SR1138, Sol Chemical, UK), moisten Wet dispersant A (X-405, Rohm and Haas Company, USA) 0.4 part, wetting dispersant B (SN-5040, Shenzhen Haichuan Chemical Co., Ltd.) 0.8 part, defoamer (Foamex Airex 901W, TEGO company) 0.3 part 0.1 part of pH regulator (AMP-95, American ANGUS), stirred for 10 minutes, and prepared premixed liquid for subsequent use;

[0031] At a rotating speed of 800r / min, 7.0 parts of pentaerythritol (600 mesh, Qingdao New Material Technology Industrial Park Development Co., Ltd.), 14 parts of melamine (400 mesh, Jinan Jinyingtai Chemical Co., Ltd.) and ammonium polyphosphate (polymerization) were added successively in the formula. Polymerization degree > 1000, 24 parts of Prosafefur (Qingyuan) Phosphorus Chemical Co., Ltd.), 5 parts of fir...

Embodiment 2

[0035] Under the rotating speed of 500r / min, add 20 parts of tap water in the formula successively, 6 parts of antifreeze agent (propylene glycol, Dow Chemical), 0.4 part of anticorrosion and antifungal agent (SR1138, Sol Chemical, UK), wetting and dispersing agent A ( X-405, U.S. Rohm and Haas Company) 0.6 part, wetting and dispersing agent B (Orotan731A, U.S. Rohm and Haas Company) 0.8 part, defoamer (FoamStarA36, Corning) 0.3 part, pH regulator (AMP- 95, U.S. ANGUS) 0.2 part, stirred for 5 minutes, prepared premixed solution for subsequent use;

[0036] Under the rotating speed of 600r / min, add 6 parts of pentaerythritol (600 mesh, Qingdao New Material Technology Industrial Park Development Co., Ltd.) in the formula successively, 12 parts of melamine (400 mesh, Jinan Jinyingtai Chemical Co., Ltd.), ammonium polyphosphate (polymerized Degree of polymerization > 1000, 23 parts of Prosafefur (Qingyuan) Phosphorus Chemical Co., Ltd.), 5 parts of fireproof filler (glass powder, ...

Embodiment 3

[0040] Under the rotating speed of 500r / min, add successively 17 parts of tap water in the formula, 6 parts of antifreeze agent (propylene glycol, Dow Chemical), 0.2 part of anticorrosion and antifungal agent (EPW, British Thor Chemical), wetting and dispersing agent A ( Hydropalat 875, Shenzhen Haichuan Chemical Co., Ltd.) 0.4 part, wetting and dispersing agent B (Orotan1288, Rohm and Haas, USA) 1.2 part, defoamer (FoamStarA36, Corning) 0.5 part, pH regulator (AMP-95, 0.2 parts of American ANGUS), stirred for 5 minutes, and prepared a premixed solution for subsequent use;

[0041] Under the rotating speed of 800r / min, add 8 parts of pentaerythritol (600 mesh, Qingdao New Material Science and Technology Industrial Park Development Co., Ltd.), 14 parts of melamine (400 mesh, Jinan Jinyingtai Chemical Co., Ltd.) in the formula successively, ammonium polyphosphate (polymerized Degree of polymerization > 1000, 22 parts of Prosafefur (Qingyuan) Phosphorus Chemical Co., Ltd.), 5 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fire resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com