Piston ring and piston device

A technology of piston rings and pistons, which is applied in the field of piston rings, can solve the problems of insufficient reduction of vertical material aggressiveness, reduction of film friction coefficient, rough surface of piston materials, etc., achieve excellent aluminum adhesion prevention effect, and inhibit wear and thermal decomposition , Excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

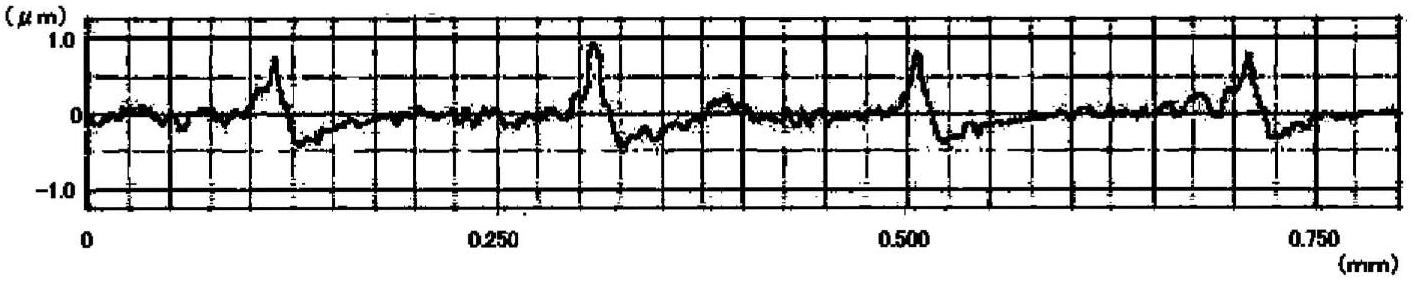

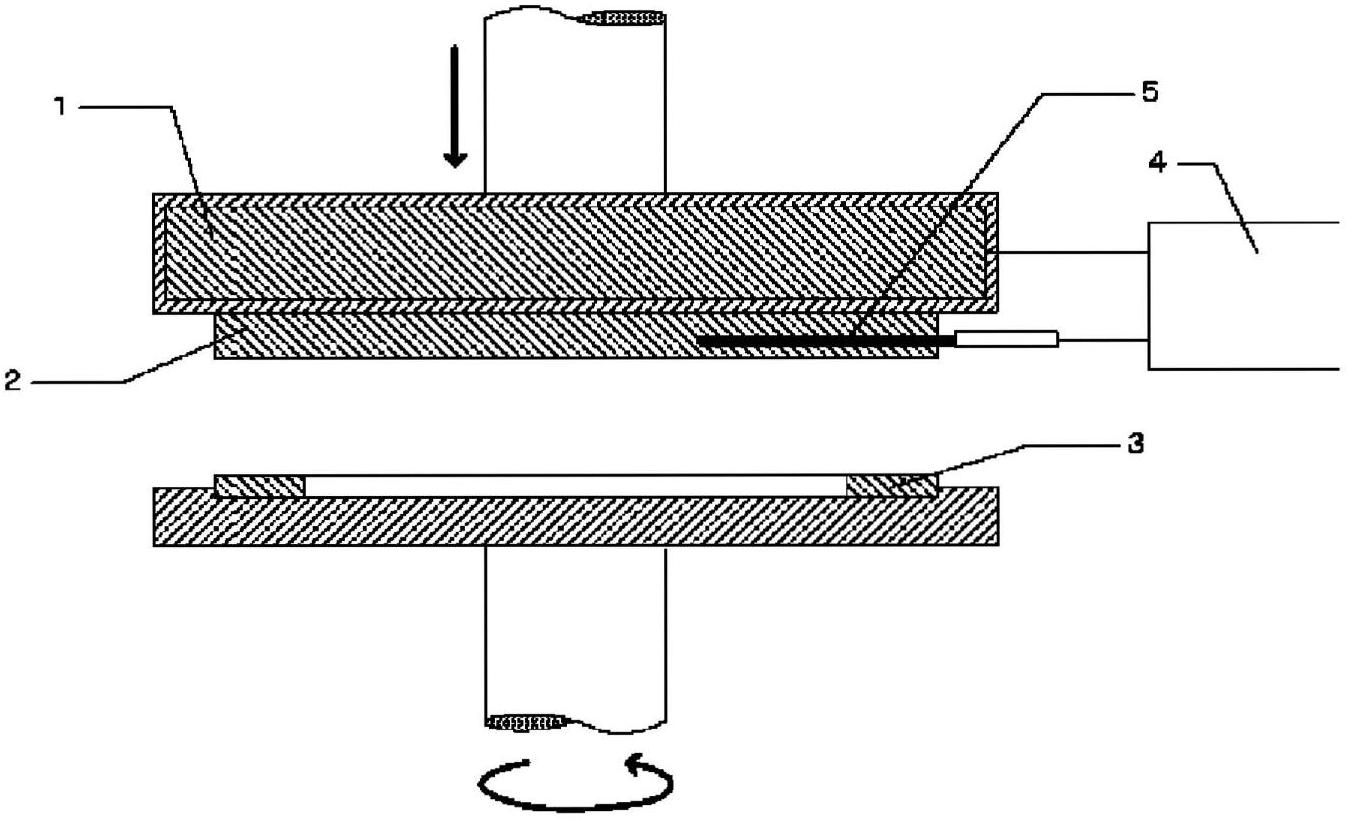

[0054] A CrN film with a thickness of approximately 30 μm was formed on the outer peripheral surface of a piston ring made of low-chromium steel by ion plating. After alkali degreasing the obtained piston ring, it was immersed in a manganese phosphate aqueous solution heated to about 80° C. for 5 minutes to form a manganese phosphate film with a thickness of about 2 μm on the surface of the piston ring other than the outer peripheral surface.

[0055] Alumina (Al 2 o 3 ) powder was added to polyimide (PI) varnish (RIKACOAT SN-20 manufactured by New Nippon Chemical Co., Ltd.), and after fully stirring using a mixer, it was passed through a three-roll mill with the roller interval adjusted to the minimum, thereby A coating liquid is prepared. Here, the amount of alumina powder added was adjusted to 10% with respect to the mass of the entire film. The coating liquid was sprayed on the upper and lower sides of the piston ring on which the manganese phosphate film was formed, dr...

Embodiment 2

[0058] Films were formed on the upper and lower sides of the piston ring in the same manner as in Example 1 except that silicon carbide (SiC) powder having an average particle diameter of 0.5 μm was used instead of alumina powder as hard particles. The thickness (one side) of the obtained film was about 10 μm, and the film hardness HV was 41.

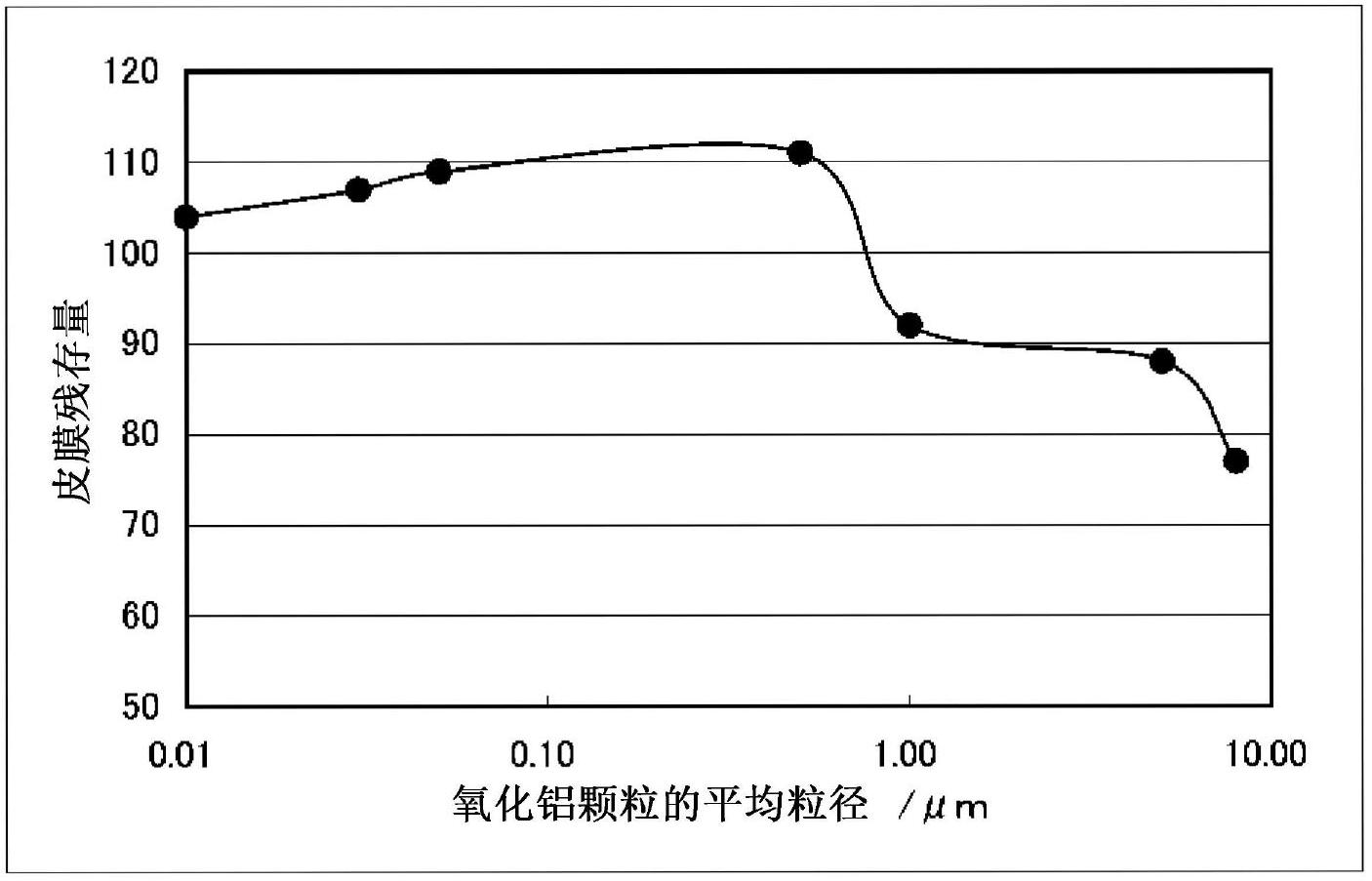

Embodiment 3~9

[0060] The average particle size used is 0.008 μm (Example 3), 0.01 μm (Example 4), 0.03 μm (Example 5), 0.05 μm (Example 6), 1 μm (Example 7), 5 μm (Example 8) ) and 8 μm (Example 9) were used as hard particles, and a film was formed on the upper and lower sides of the piston ring in the same manner as in Example 1. The obtained film had a thickness of about 10 μm. In addition, the film hardness of each film was measured, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com