Method for producing acid by hydrothermally degrading waste liquid crystal display polaroids

A liquid crystal display, hydrothermal degradation technology, applied in chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., to achieve the effects of wide processing range, high efficiency and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

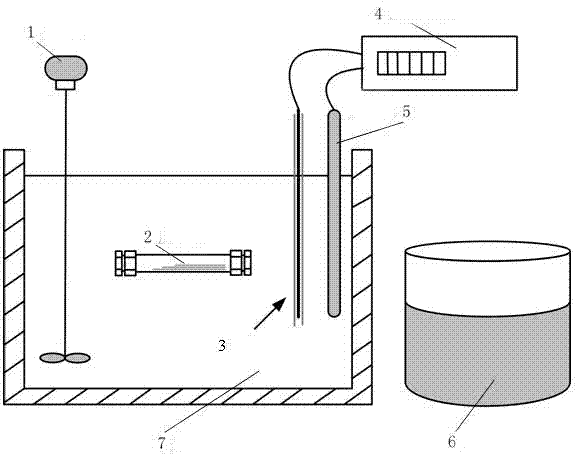

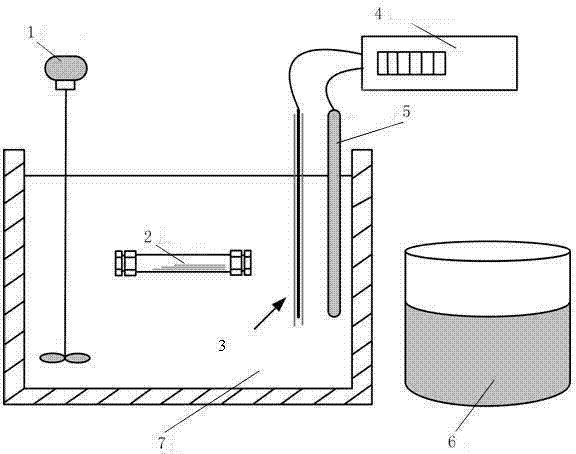

Image

Examples

Embodiment 1

[0030] Example 1: Degradation of waste liquid crystal display polarizers to produce acetic acid

[0031] (1) Use the polarizer contained in the waste liquid crystal display as the material, cut it into small pieces, and then put it into a crusher for crushing, so that the particle size of the crushed material is less than 2mm.

[0032] (2) The broken material of the polarizer obtained in step (1) is used as a reactant, deionized water is used as a solvent, hydrogen peroxide is used as an oxidant, and the mass ratio of the polarizer to water is between 0.01-0.05, and placed in a high temperature and high pressure resistant, In the corrosion-resistant reactor, the volume of water added is 50-80% of the reactor volume.

[0033] (3) Place the reactor containing the mixture of polarizer and water in step (2) in a temperature-controlled salt bath furnace, control the reaction temperature at 250°C, 275°C, 300°C, 325°C, 350°C, and heat React for 5 minutes; heat at 350°C for 1 minute,...

Embodiment 2

[0036] Example 2: Degradation of waste liquid crystal display polarizers to produce lactic acid

[0037] (1) Use the polarizer contained in the waste liquid crystal display as the material, cut it into small pieces, and then put it into a hammer crusher to crush it, so that the particle size of the crushed material is less than 2mm.

[0038] (2) The broken material of the polarizer obtained in step (1) is used as a reactant, deionized water is used as a solvent, hydrogen peroxide is used as an oxidant, and the mass ratio of the polarizer to water is between 0.01-0.05, and placed in a high temperature and high pressure resistant, In the corrosion-resistant reactor, the volume of water is 50-80% of the reactor volume.

[0039] (3) Place the reactor containing the mixture of polarizer and water in step (2) in a temperature-controlled salt bath furnace, control the reaction temperature at 250°C, 275°C, 300°C, 325°C, 350°C, and heat React for 5 minutes; heat at 350°C for 1 minute,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com