Preparation method of organic silicon adsorption material with purification function

An adsorption material and organosilicon technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of complex synthesis methods and low separation efficiency, and achieve simple steps and reaction processes, good hydrophobicity, and low price low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

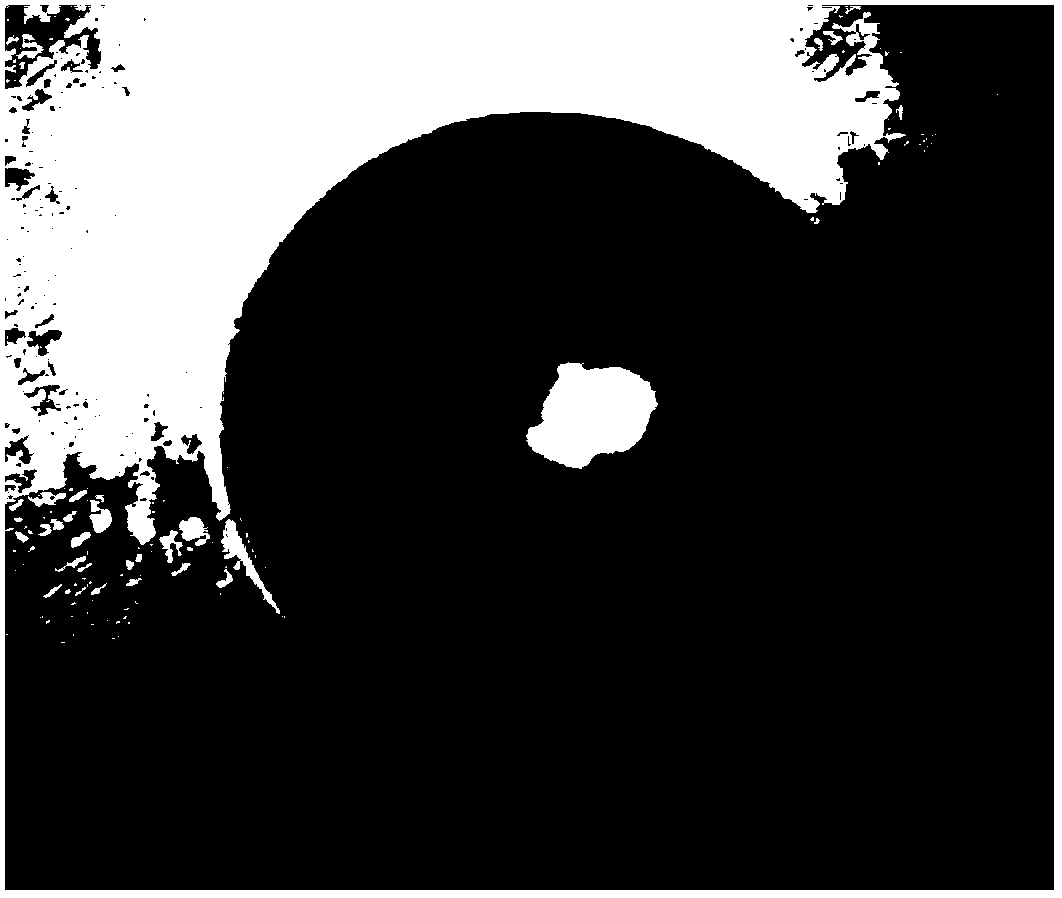

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: the preparation method of the organosilicon adsorption material with purification function in this embodiment is carried out according to the following steps:

[0021] 1. Use ethanol, isopropanol or methanol as a solvent to prepare a silicone resin solution with a mass concentration of 15% to 50%, dissolve the catalyst in water or ethanol, and prepare a catalyst with a concentration of 0.2mol / L to 2.5mol / L solution, the silicone resin is a methyl silicone resin, and the catalyst is hydrochloric acid or ammonia;

[0022] 2. Under stirring conditions, add 5ml~10ml of catalyst solution dropwise into 10ml~20ml of silicone resin solution, and stir for 3min~5min to obtain organosilicon sol;

[0023] 3. Take 10ml~20ml of organic silica sol, add 0.2g~2g of polymer microspheres with a size of 0.5μm~20μm, seal it after ultrasonic dispersion, heat at 60°C for 20h~40h, then heat up to 70°C for 20h~40h, and get wet gel;

[0024] 4. Dissolve the wet gel obt...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that the polymer microspheres described in step 3 are polystyrene microspheres or polymethyl methacrylate microspheres. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the organic solvent in step 4 is N,N-dimethylformamide, xylene or tetrahydrofuran. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com