Method for preparing porous spherical stannous oxide nano material

A stannous oxide and nanomaterial technology, applied in the directions of tin oxide and nanotechnology, can solve the problems of increasing the difficulty of stannous oxide nanomaterials, reducing the purity of synthetic products, increasing production costs, etc., and achieving low cost, uniform appearance, The effect of avoiding the formation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

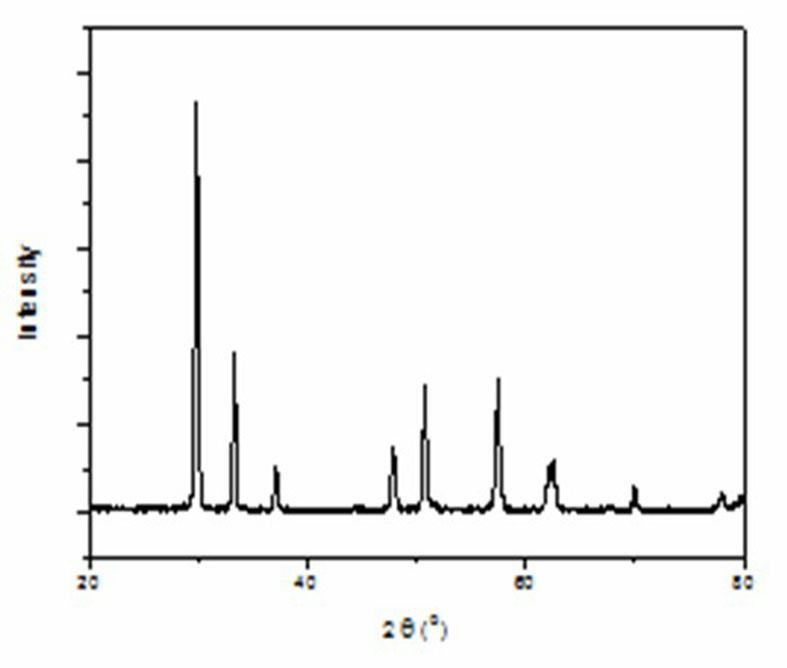

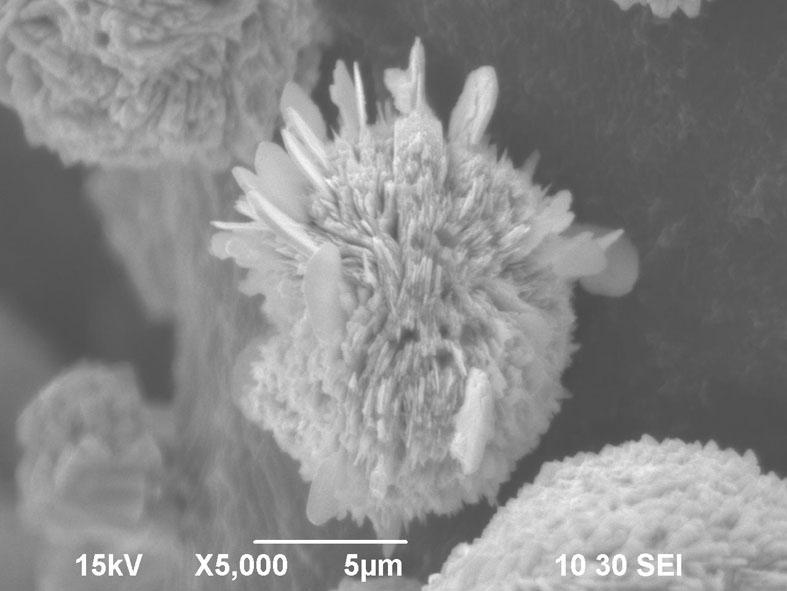

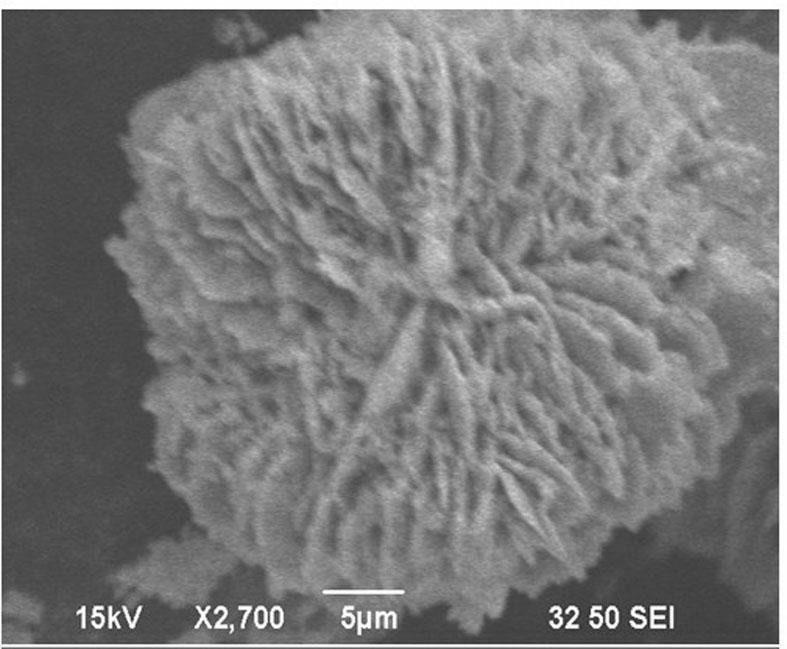

[0022] Accurately weigh 1.128g of stannous oxide dihydrate (SnCl 2 2H 2 O) add in the clean beaker that fills 20mL dehydrated alcohol, be placed on the magnetic stirrer and stir, until the stannous oxide dihydrate crystal dissolves completely. Then accurately weigh 0.6g of sodium hydroxide and add it to a clean beaker filled with 20mL of absolute ethanol, and stir until the sodium hydroxide is completely dissolved. Then, slowly drop the dehydrated ethanol solution dissolved with sodium hydroxide into the dehydrated ethanol solution of stannous oxide, stir while dropping, and continue stirring for 10 min after the dropwise addition to obtain the stannous oxide precursor; The molar concentration of stannous chloride dihydrate in the medium is 0.125mol / L, and the molar ratio of stannous chloride dihydrate to sodium hydroxide is 1:3. The obtained stannous oxide precursor solution was charged into a polytetrafluoroethylene-lined autoclave with a volume of 50 mL. React for 6 hour...

example 2

[0024] Accurately weigh 1.128g of stannous oxide dihydrate and add it to a clean beaker filled with 20mL of absolute ethanol, place it on a magnetic stirrer and stir slowly until the crystals of stannous oxide dihydrate are completely dissolved. Then accurately weigh 0.5 g of solid sodium hydroxide and add it to a clean beaker filled with 20 mL of absolute ethanol, and stir until the sodium hydroxide is completely dissolved. Then, slowly drop the dehydrated ethanol solution that is dissolved with sodium hydroxide into the dehydrated ethanol solution of stannous oxide, stir while dropping, and then stir for 10 min after the dropwise addition to obtain the stannous oxide precursor; The molar concentration of stannous chloride dihydrate in the medium is 0.125mol / L, and the molar ratio of stannous chloride dihydrate to sodium hydroxide is 1:2.5. The configured stannous oxide precursor solution was filled into a polytetrafluoroethylene-lined autoclave with a lining volume of 50 mL....

example 3

[0026] Accurately weigh 1.128g of stannous oxide dihydrate and add it to a clean beaker filled with 20mL of absolute ethanol, place it on a magnetic stirrer and stir slowly until the crystals of stannous oxide dihydrate are completely dissolved. Then accurately weigh 0.7g of sodium hydroxide powder and add it to a clean beaker filled with 20mL of absolute ethanol, and stir until the sodium hydroxide is completely dissolved. Then, slowly drop the dehydrated ethanol solution dissolved with sodium hydroxide into the dehydrated ethanol solution of stannous oxide, stir while dropping, and continue stirring for 10 min after the dropwise addition to obtain the stannous oxide precursor; The molar concentration of stannous chloride dihydrate in the medium is 0.125mol / L, and the molar ratio of stannous chloride dihydrate to sodium hydroxide is 1:3.5. Then the obtained stannous oxide precursor solution was loaded into a polytetrafluoroethylene-lined autoclave with a volume of 50 mL. Rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com