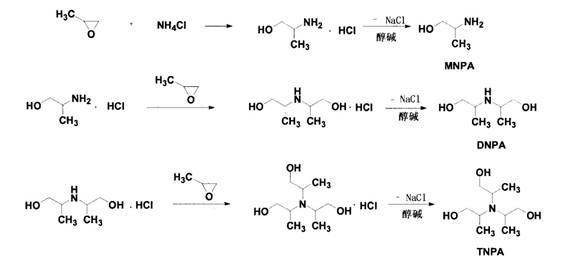

Method for preparing MNPA, DNPA and TNPA

A new technology of propanolamine and propanolamine hydrochloride is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc. It can solve the problems of decomposition into propylene glycol, simple investment and low investment, and achieve product quality Good, low equipment requirements, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Mix 214 grams (4 moles) of ammonium chloride in 144 ml of deionized water, then inject nitrogen to replace the air in the autoclave to evacuate, and then inject nitrogen repeatedly to remove the air. After that, start to inject 280 grams of PO under stirring, gradually increase the temperature and control the reaction to 60~80°C, and control the pressure to ≤0.3MPa. After the pressure in the kettle is reduced to zero (gauge pressure), the reaction is completed. Nitrogen was introduced into the kettle to blow off the residual PO, recovered by ammonium chloride aqueous solution, dehydrated under reduced pressure, cooled, crystallized and filtered, washed with a small amount of water, drained, and vacuum-dried at ≤ 50°C to obtain MNPA. HCl, then add it to the methanol solution with equivalent caustic soda under stirring, free MNPA, filter out most of the sodium chloride at lower temperature, recover methanol, remove water and distill under reduced pressure, control 20mmHg a...

Embodiment 2

[0037] Mix 214 grams of ammonium chloride in 144 ml of deionized water, then inject nitrogen to replace the air in the reactor, vacuumize the air to remove it, then inject a total of 280 grams of PO under stirring, gradually increase the temperature and control the reaction to 60~80 ° C, the pressure ≤ 0.3MPa, until the internal pressure of the kettle reaches zero reaction. Recover residual PO, remove water under reduced pressure, cool down, crystallize and filter, wash the filter cake with methanol, drain, and dry to obtain MNPA. About 90 grams of HCl was recovered from the washing liquid and combined with the filtrate, and put into the kettle together with the "MNPA.HCl, TNPA.HCl mixture" in Example 1, and gradually injected about 230 grams of PO under stirring. Pressure ≤ 0.3MPa, stop injecting PO until the gauge pressure does not drop, and then stir for 30 minutes to complete the reaction, recover excess PO, remove water, cool down, crystallize and filter, wash with methan...

Embodiment 3

[0039] Get MNPA in embodiment 2. Add 100 grams of dry HCl to the methanol solution containing the equivalent of sodium methoxide in portions, free MNPA under stirring, filter out sodium chloride, recover methanol, and then distill under reduced pressure, control 20mmHg to take a fraction at about 81-83°C to obtain MNPA , content ≥ 95%,.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com