Degreasing liquid soap and preparation method thereof

A hand sanitizer and degreasing technology, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of irritating the skin of hands, strong volatility of gasoline, dry skin, etc., and achieve reasonable raw materials, good emulsification, Strong degreasing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: present embodiment degreasing hand sanitizer is made up of each raw material of following percentage by weight: 8% ammonium lauryl sulfonate, 20% coconut oil fatty acid diethanolamide, 0.5% glycerol, 0.5% Sodium polyphosphate, 0.2% sodium benzoate, 0.5% citric acid, 0.01% apple green, 0.5% NaCl, 0.01% 200 mesh walnut shell particles, 0.1% lavender essence and the rest of water.

[0020] The preparation method is as follows: first dissolve ammonium dodecylsulfonate, coconut oil fatty acid diethanolamide, glycerin, sodium polyphosphate and sodium benzoate in water; add NaCl and 200-mesh walnut shell particles and stir evenly, then add lemon Adjust the pH to 6-7 with acid, add a small amount of apple green and lavender essence and stir well to adjust the color and fragrance; finally add water and mix well.

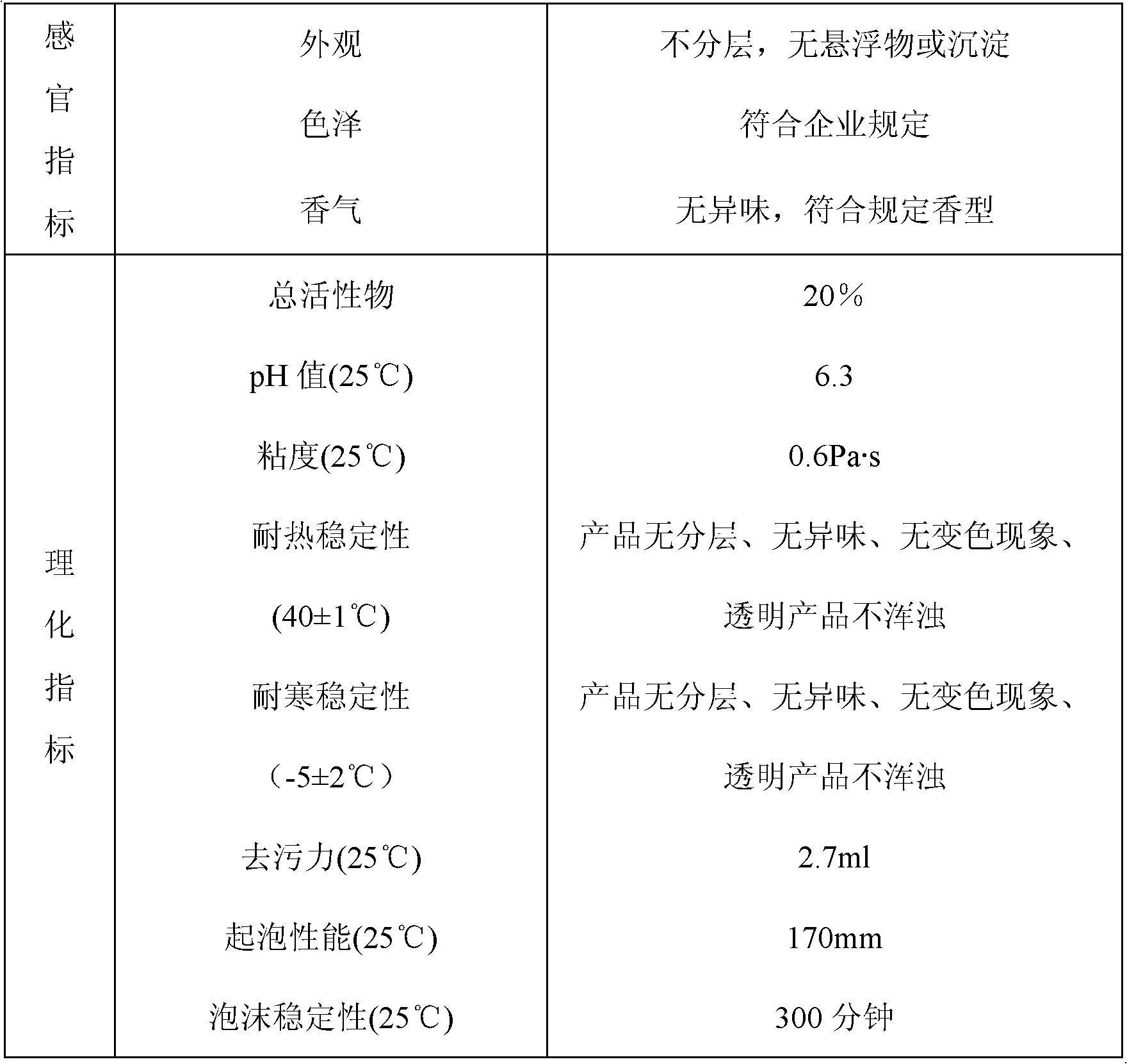

[0021] Product analysis method: at 25°C, use the pHS-2F digital pH meter to measure the pH value of the hand sanitizer; at 25°C, use the AHY-NDJ-1 rotati...

Embodiment 2

[0025] Embodiment 2: present embodiment degreasing hand sanitizer is made up of each raw material of following percentage by weight: 13% fatty alcohol polyoxyethylene ether ammonium sulfate, 12% alkylphenol polyoxyethylene ether, 3% ethylene glycol, 3% sodium polyphosphate, 1% sodium benzoate, 0.05% citric acid, 0.1% rose bengal, 5% NH 4 Cl, 0.1% of 150 mesh walnut shell particles, 0.01% of apple essence and the rest of the water.

[0026] The preparation method is: first dissolve fatty alcohol polyoxyethylene ether ammonium sulfate, alkylphenol polyoxyethylene ether, ethylene glycol, sodium polyphosphate, and sodium benzoate in water; add NH 4 After Cl and 150 mesh walnut shell particles are mixed evenly, then add citric acid to adjust the pH to 6-7, add a small amount of rose red and apple essence and stir evenly to adjust the color and fragrance; finally add water and mix evenly.

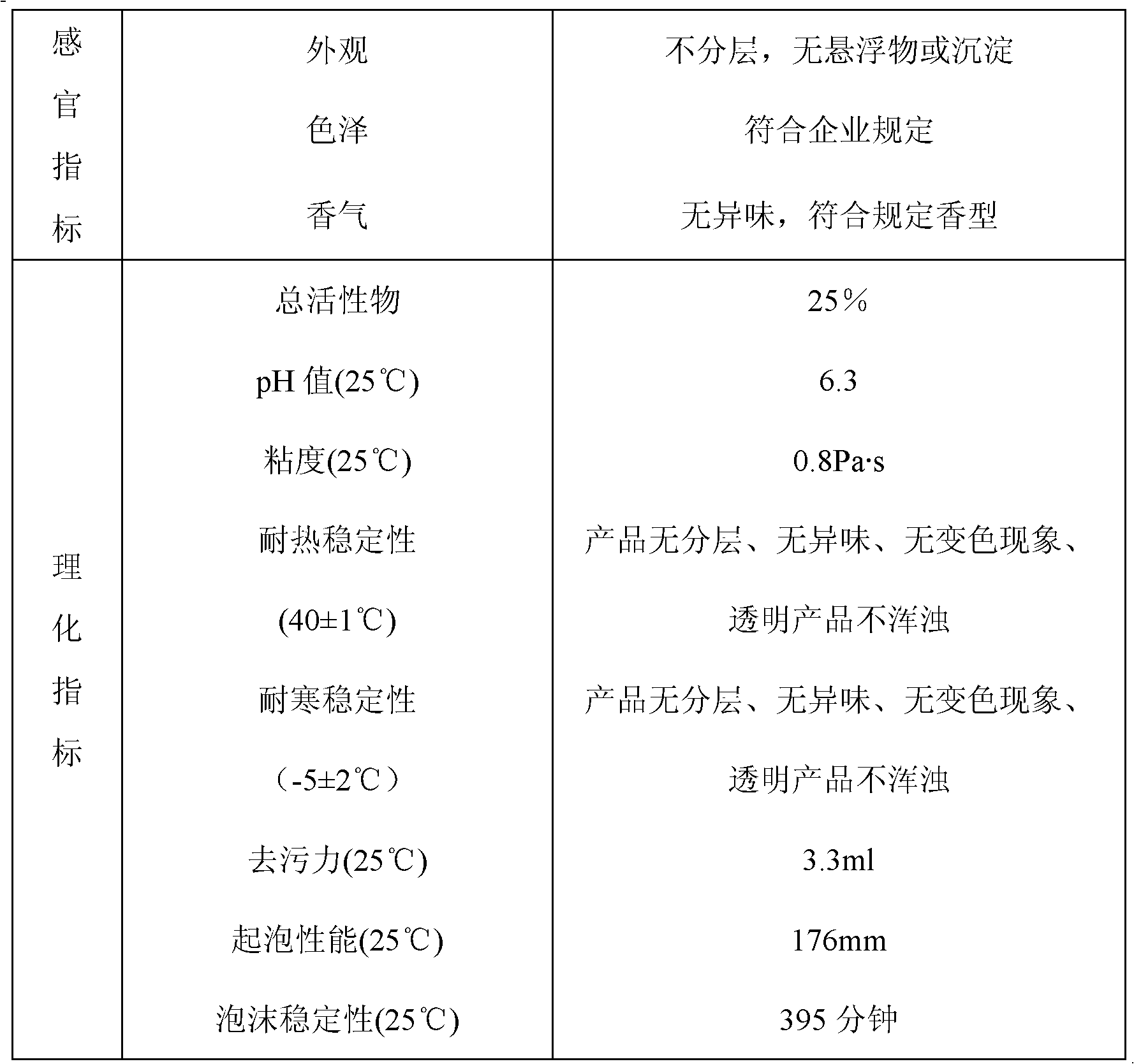

[0027] The product analysis method is the same as in Example 1.

[0028] The sensory and ph...

Embodiment 3

[0031] Embodiment 3: present embodiment degreasing hand sanitizer is made up of each raw material of following percentage by weight: 15% fatty alcohol polyoxyethylene ether sodium sulfate, 15% fatty alcohol polyoxyethylene ether, 2% medicinal lanolin, 2% sodium edetate, 0.7% sodium benzoate, 0.3% citric acid, 0.05% rose bengal, 3% NaCl, 0.05% 100 mesh walnut shell particles, 0.03% lavender essence and the balance of water.

[0032] The preparation method is: first dissolve fatty alcohol polyoxyethylene ether sodium sulfate, fatty alcohol polyoxyethylene ether, medicinal lanolin, sodium edetate, and sodium benzoate in water; add NaCl and 100-mesh walnut shell particles and stir evenly , then add citric acid to adjust the pH to 6-7, add rose red and lavender essence and stir well to adjust the color and fragrance; finally add water and mix well.

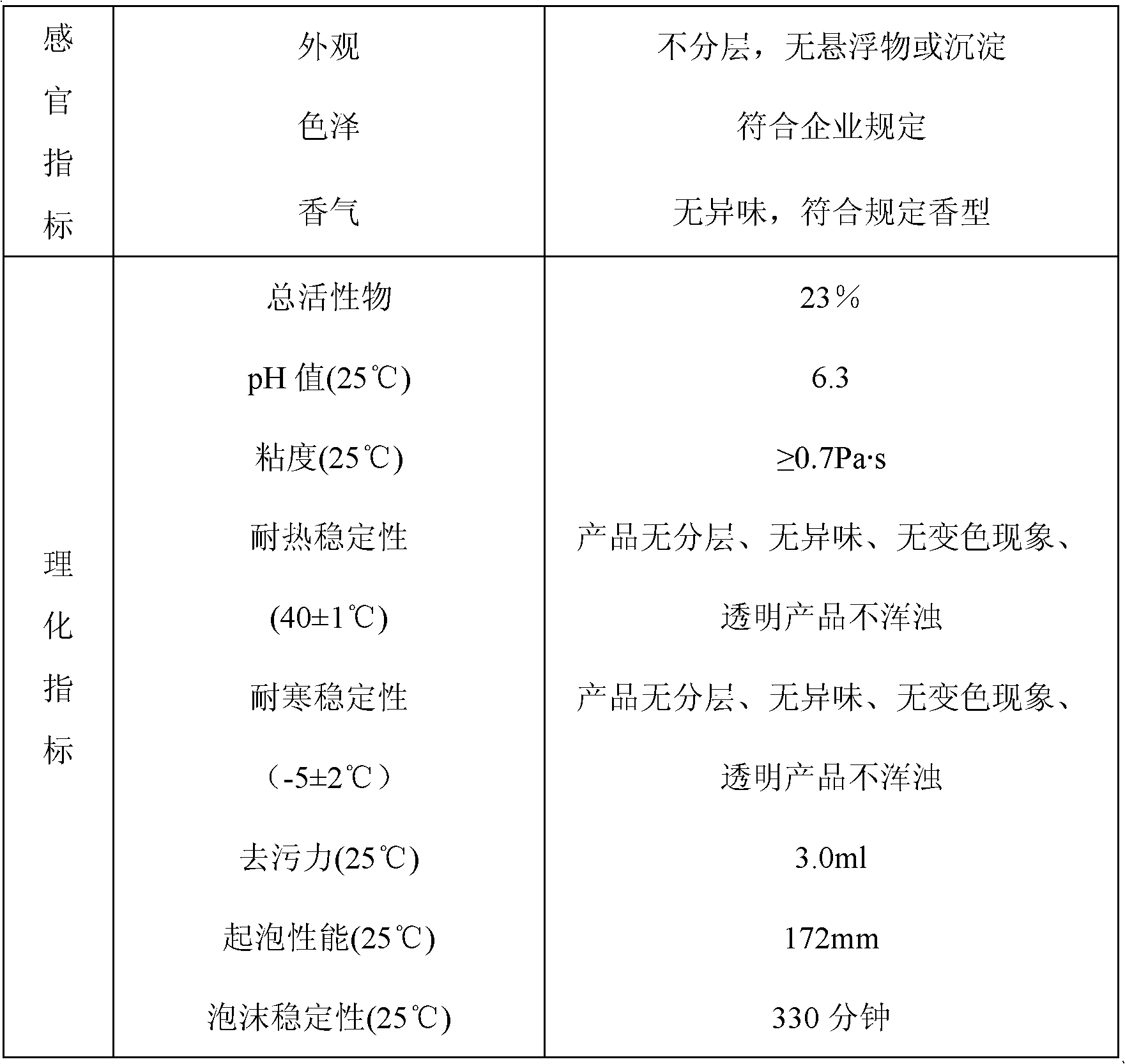

[0033] The product analysis method is the same as in Example 1.

[0034] The sensory and physical and chemical properties of the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com