Ofloxacin molecular inclusion nanometer preparation and preparation method thereof

A technology of ofloxacin and nano preparations, applied in the field of medicine, can solve the problems of reduced curative effect, drug waste, and reduced bioavailability, and achieve the effects of simple preparation process, improved utilization, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

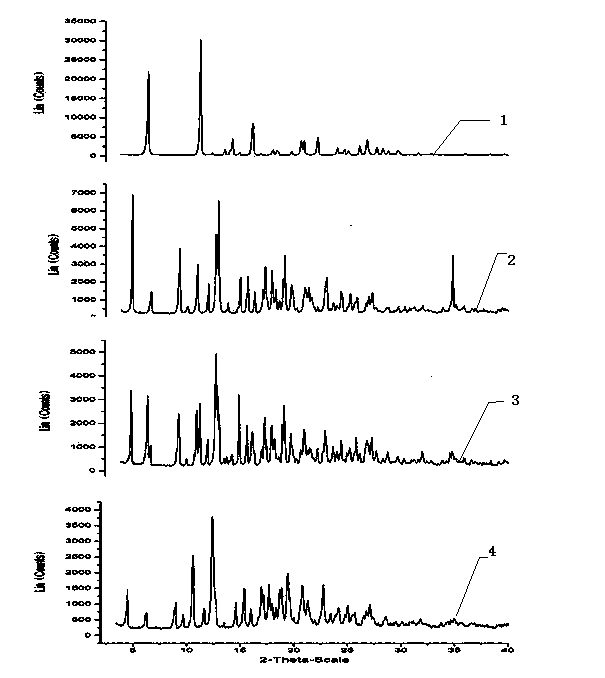

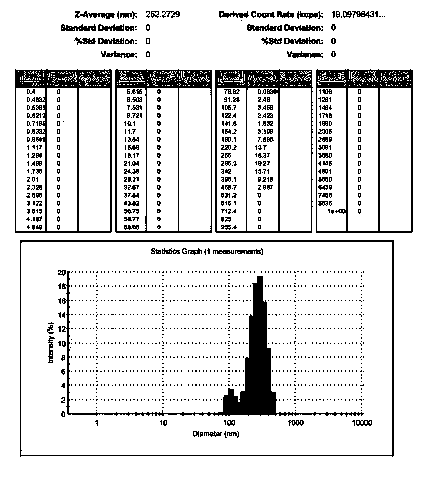

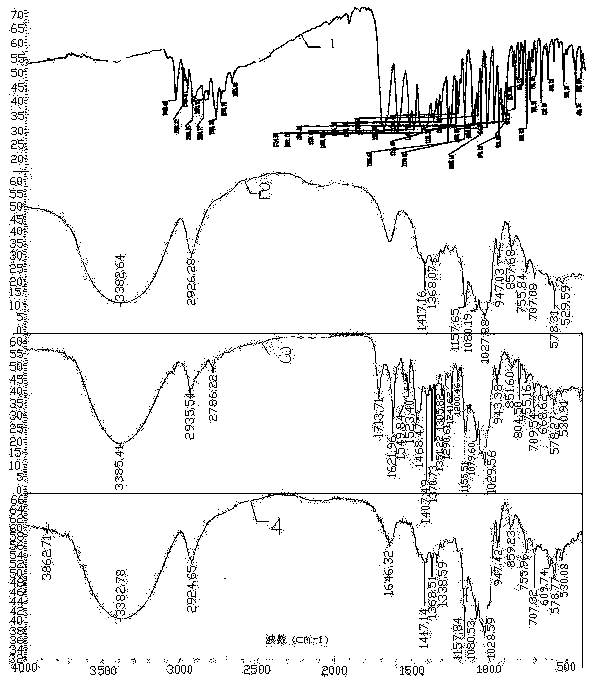

Image

Examples

Embodiment 1

[0028] (1) The molecular inclusion nano-preparation of ofloxacin is mainly made of the following raw materials in parts by weight:

[0029] Ofloxacin 0.5 parts by weight,

[0030] 5 parts by weight of β-cyclodextrin,

[0031] 0.05 parts by weight of acetic acid,

[0032] 0.5 parts by weight of hydroxypropyl methylcellulose.

[0033] (2) The method for preparing ofloxacin molecular inclusion nano-preparation:

[0034] Dissolve 0.5 parts by weight ofloxacin in distilled water containing 0.05 parts by weight of acetic acid; add 5 parts by weight of β-cyclodextrin to the ofloxacin solution under 100KHz ultrasonic conditions in a water bath at 40°C for 10 minutes Minutes; Stir and sonicate for 25 minutes under 45KHz ultrasonic conditions in a 40°C water bath; Stir and sonicate for 15 minutes under 28KHz ultrasonic conditions in a 40°C water bath; then mechanically grind for 20 minutes. After adding 0.5 parts by weight of hydroxypropylmethylcellulose, continue to grind for 20 mi...

Embodiment 2

[0036] (1) The molecular inclusion nano-preparation of ofloxacin is mainly made of the following raw materials in parts by weight:

[0037] 1 part by weight ofloxacin,

[0038] 7 parts by weight of beta-cyclodextrin,

[0039] 0.05 parts by weight of acetic acid,

[0040] 1.95 parts by weight of hydroxypropyl methylcellulose.

[0041] (2) The method for preparing ofloxacin molecular inclusion nano-preparation:

[0042] Dissolve 1 part by weight ofloxacin in distilled water containing 0.05 parts by weight of acetic acid; add 7 parts by weight of β-cyclodextrin to the ofloxacin solution under 100KHz ultrasonic conditions in a water bath at 40°C, and ultrasonic time for 10 Minutes; Stir and sonicate for 20 minutes under 45KHz ultrasonic conditions in a 40°C water bath; Stir and sonicate for 15 minutes under 28KHz ultrasonic conditions in a 40°C water bath; then mechanically grind for 25 minutes. After adding 1.95 parts by weight of hydroxypropylmethylcellulose, continue to gri...

Embodiment 3

[0044] (1) The molecular inclusion nano-preparation of ofloxacin is mainly made of the following raw materials in parts by weight:

[0045] Ofloxacin 2 parts by weight,

[0046] 6 parts by weight of hydroxypropyl-β-cyclodextrin,

[0047] 0.1 parts by weight of methanesulfonic acid,

[0048] 1.9 parts by weight of hydroxypropyl methylcellulose.

[0049] (2) The method for preparing ofloxacin molecular inclusion nano-preparation:

[0050] Dissolve 2 parts by weight ofloxacin in distilled water containing 0.1 part by weight of methanesulfonic acid; add 6 parts by weight of hydroxypropyl-β-cyclodextrin to ofloxacin under 100KHz ultrasonic conditions in a water bath at 40°C In the solution, ultrasonic time was 20 minutes; stirred and sonicated for 30 minutes under 45KHz ultrasonic conditions in a 40°C water bath; stirred and sonicated for 25 minutes under 28KHz ultrasonic conditions in a 40°C water bath; then mechanically ground for 30 minutes. After adding 1.9 parts by weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com