Preparation method of graphene-based composite separation membrane device

A graphene-based, separation membrane technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve problems such as unrealized, and achieve the effects of low cost, easy availability of raw materials, and low operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of graphene-based composite separation membrane device comprises the following steps:

[0020] 1) dissolving 1 part by weight of graphene oxide raw material in 100-5000 parts by weight of deionized water, and treating it in an ultrasonic bath of 1-50 Hz for 0.1-1 hour to obtain a graphene oxide solution;

[0021] 2) Mix 1 part by weight of graphene oxide solution with 0.0001 part by weight of alkali, stir for 0.1 to 5 hours at a temperature of 80 to 100 degrees Celsius, cool to room temperature, centrifuge, and wash with deionized water until pH = 6 to 12 , to obtain a reduced graphene oxide dispersion;

[0022] 3) Pour the graphene dispersion into a suction filter bottle lined with a filter membrane, filter for 0.1-10 hours, and dry in a vacuum oven to obtain a graphene thin layer with a thickness of 20-200nm and a filter pore size of 0.2-2μm. Graphene-based composite separation membrane made of laminated filter membrane;

[0023] 4) The graphe...

Embodiment 1

[0028] 1) Dissolving 1 part by weight of graphene oxide raw material in 100 parts by weight of deionized water, and treating it in a 1 Hz ultrasonic bath for 0.1 hour to obtain a graphene oxide solution;

[0029] 2) Mix 1 part by weight of graphene oxide solution with 0.0001 part by weight of NaOH, stir at 80 degrees Celsius for 0.1 hour, cool to room temperature, centrifuge, wash with deionized water to pH = 6, and obtain reduced graphite oxide olefin dispersion;

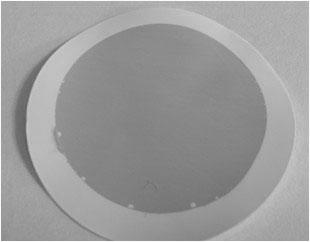

[0030] 3) Pour the graphene dispersion into a suction filter bottle lined with anodized aluminum, filter for 0.1 hour, and dry in a vacuum oven to obtain a graphene thin layer with a thickness of 200nm and a filter membrane with a filter pore size of 0.2μm. The graphene-based composite separation membrane formed;

[0031] 4) The graphene-based composite separation membrane is placed in a cross-flow filtration device to obtain a graphene-based composite separation membrane device.

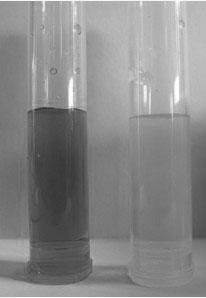

[0032] After the above steps, t...

Embodiment 2

[0034] 1) Dissolving 1 part by weight of graphene oxide raw material in 5000 parts by weight of deionized water, and treating it in a 50 Hz ultrasonic bath for 1 hour to obtain a graphene oxide solution;

[0035] 2) Mix 1 part by weight of graphene oxide solution with 0.0001 part by weight of KOH, stir at 100 degrees Celsius for 5 hours, cool to room temperature, centrifuge, wash with deionized water until pH = 12, and obtain reduced graphite oxide olefin dispersion;

[0036] 3) Pour the graphene dispersion into a suction filter bottle filled with mixed cellulose esters, filter for 10 hours, and dry in a vacuum oven to obtain a graphene thin layer with a thickness of 20nm and a filter membrane with a filter pore size of 2 μm. The graphene-based composite separation membrane formed;

[0037] 4) Putting the graphene-based composite separation membrane in a dead-end filter device to obtain a graphene-based composite separation membrane device.

[0038] After the above steps, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filter pore size | aaaaa | aaaaa |

| Filter pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com