Preparation method of ultrahigh-viscosity sodium carboxymethyl cellulose

A technology of sodium carboxymethyl cellulose and viscosity, applied in the field of chemical modification of natural polymer materials, can solve the problems of inability to meet customers and large market demand, and achieve the effects of simple process, low equipment investment and high viscosity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

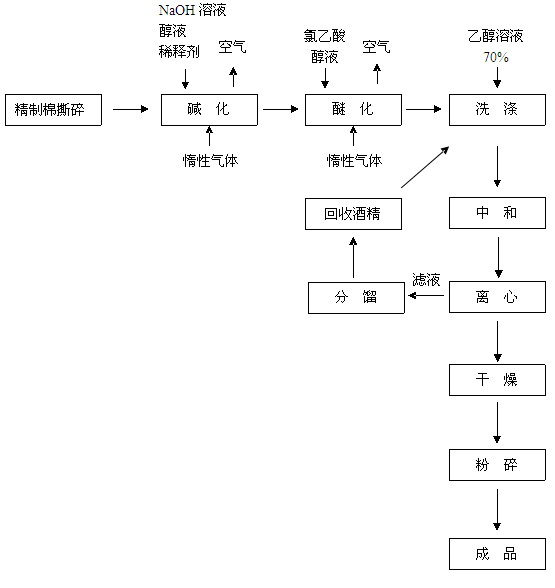

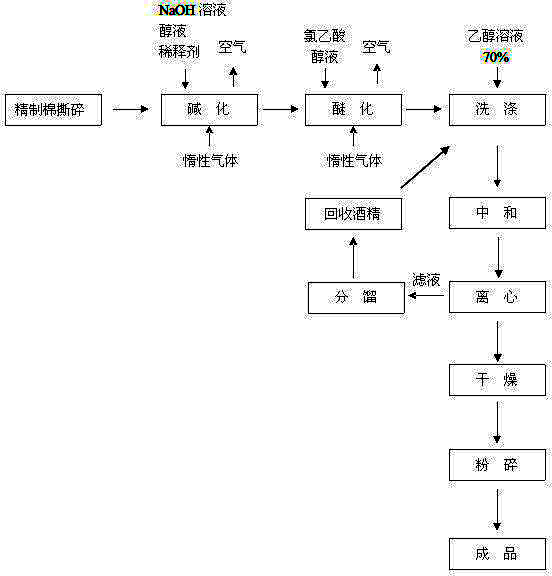

Method used

Image

Examples

Embodiment 1

[0029] A certain amount of shredded refined cotton, mixed with 1.5 times the mass of ethanol solution and 0.3 times the mass of water, is put into the reactor, and then 0.96 times the mass of sodium hydroxide aqueous solution and 0.13 times the mass of sodium hydroxide solid Put it into the reactor. After feeding, remove the air in the reactor to make the vacuum degree reach -0.08MPa, fill the reactor with inert gas to make the internal pressure of the reactor greater than 0.02MPa, repeat the above vacuuming and inert filling Gas operation 2-3 times, get rid of the air in the reactor as much as possible, after stirring and alkalizing for 70 minutes, spray the ethanol solution of chloroacetic acid with 1.18 times of quality evenly into the reactor, get rid of the air in the reactor, make The vacuum degree reaches -0.08MPa, and then the inert gas is filled into the reactor, so that the internal pressure of the reactor is greater than 0.02MPa, and then the etherification reaction ...

Embodiment 2

[0031] A certain amount of shredded refined cotton, mixed with 1.0 times the mass of ethanol solution and 0.8 times the mass of water, is put into the reactor, and then 0.60 times the mass of sodium hydroxide aqueous solution and 0.30 times the mass of sodium hydroxide solid Put it into the reactor. After feeding, remove the air in the reactor to make the vacuum degree reach -0.08MPa, fill the reactor with inert gas to make the internal pressure of the reactor greater than 0.02MPa, repeat the above vacuuming and inert filling The operation of the gas is 2-3 times, try to get rid of the air in the reactor, after stirring and alkalizing for 50 minutes, spray the ethanol solution of chloroacetic acid with 1.50 times the quality evenly into the reactor, and get rid of the air in the reactor, so that The vacuum degree reaches -0.08MPa, and then the inert gas is filled into the reactor, so that the internal pressure of the reactor is greater than 0.02MPa, and then the etherification ...

Embodiment 3

[0033] A certain amount of shredded refined cotton, mixed with 2.0 times the mass of ethanol solution and 0.8 times the quality of water, is put into the reactor, and then 0.78 times the quality of sodium hydroxide aqueous solution and 0.25 times the quality of sodium hydroxide solid Put it into the reactor. After feeding, remove the air in the reactor to make the vacuum degree reach -0.08MPa, fill the reactor with inert gas to make the internal pressure of the reactor greater than 0.02MPa, repeat the above vacuuming and inert filling Gas operation 2-3 times, get rid of the air in the reactor as much as possible, after stirring and alkalizing for 60 minutes, spray the ethanol solution of chloroacetic acid with 1.24 times of quality evenly into the reactor, get rid of the air in the reactor, make The vacuum degree reaches -0.08MPa, and then the inert gas is filled into the reactor, so that the internal pressure of the reactor is greater than 0.02MPa, and then the etherification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com