Method for preparing high-strength hydrogel with macromolecular microgel composite structure

A technology of composite structure and microgel, which is applied in the field of preparation of high-strength hydrogel, can solve the problems of poor improvement of hydrogel mechanical properties, etc., and achieve the effect of wide application range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

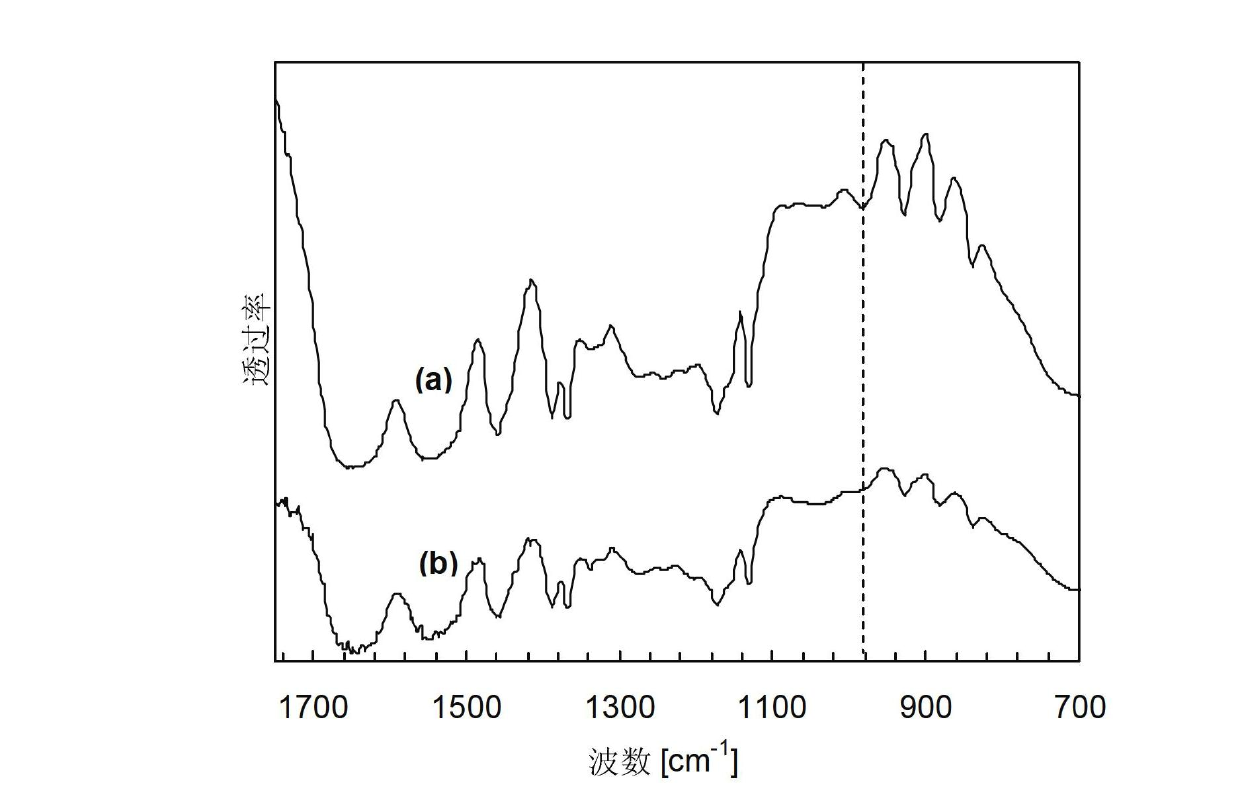

Image

Examples

Embodiment 1

[0021] In this example, the process steps for preparing a high-strength hydrogel with a polymer microgel composite structure are as follows:

[0022] (1) Preparation of poly(N-isopropylacrylamide) microgel aqueous dispersion

[0023] The first monomer N-isopropylacrylamide, cross-linking agent N, N-methylenebisacrylamide, surfactant sodium lauryl sulfate (HLB40), initiator potassium persulfate and deionized water as Raw materials, the ratio of raw materials is: add 20mmol of N-isopropylacrylamide, 0.8mmol of N,N-methylene bisacrylamide, 0.6g of sodium lauryl sulfate, and 0.2 grams of potassium persulfate per 100 mL of deionized water. mmol; Add N-isopropylacrylamide, N,N-methylenebisacrylamide, sodium lauryl sulfate, potassium persulfate and deionized water into the reaction vessel and mix well, then fill with nitrogen to remove oxygen Seal the reaction vessel and react at 60°C for 20 minutes under stirring. After the reaction time expires, cool the reaction product to 15°C w...

Embodiment 2

[0027] In this example, the process steps for preparing a high-strength hydrogel with a polymer microgel composite structure are as follows:

[0028] (1) Preparation of poly(N-isopropylacrylamide) microgel aqueous dispersion

[0029]The first monomer N-isopropylacrylamide, cross-linking agent N, N-methylenebisacrylamide, surfactant sodium lauryl sulfate (HLB40), initiator potassium persulfate and deionized water as Raw materials, the ratio of raw materials is: add 20mmol of N-isopropylacrylamide, 0.8mmol of N,N-methylene bisacrylamide, 0.6g of sodium lauryl sulfate, and 0.2 grams of potassium persulfate per 100 mL of deionized water. mmol; Add N-isopropylacrylamide, N,N-methylenebisacrylamide, sodium lauryl sulfate, potassium persulfate and deionized water into the reaction vessel and mix well, then fill with nitrogen to remove oxygen Seal the reaction vessel and react at 60°C for 10 minutes under stirring. After the reaction time expires, cool the reaction product to 10°C wi...

Embodiment 3

[0033] In this example, the process steps for preparing a high-strength hydrogel with a polymer microgel composite structure are as follows:

[0034] (1) Preparation of poly(N-isopropylacrylamide) microgel aqueous dispersion

[0035] The first monomer N-isopropylacrylamide, cross-linking agent N, N-methylenebisacrylamide, surfactant sodium lauryl sulfate (HLB40), initiator potassium persulfate and deionized water as Raw materials, the ratio of raw materials is: add 20mmol of N-isopropylacrylamide, 0.8mmol of N,N-methylene bisacrylamide, 0.6g of sodium lauryl sulfate, and 0.2 grams of potassium persulfate per 100 mL of deionized water. mmol; Add N-isopropylacrylamide, N,N-methylenebisacrylamide, sodium lauryl sulfate, potassium persulfate and deionized water into the reaction vessel and mix well, then fill with nitrogen to remove oxygen Seal the reaction vessel and react at 60°C for 30 minutes under stirring. After the reaction time expires, cool the reaction product to 10°C w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com