Surface-enhanced Raman scattering active substrate and preparation method thereof

A surface-enhanced Raman and active substrate technology, applied in Raman scattering, spinning solution preparation, rayon manufacturing, etc., can solve the problem of limited range of change and achieve the effect of a wide range of wavelengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Synthesis of Gold-Silver Alloy Nanoparticles

[0026] Add 2.4 g of polyvinyl alcohol (PVA) into 13.6 g of water, slowly raise the temperature to 80°C, heat for 1 hour, the PVA is completely dissolved, and the obtained PVA solution is a colorless, transparent and viscous uniform solution. The mass fraction of the PVA solution is 15%.

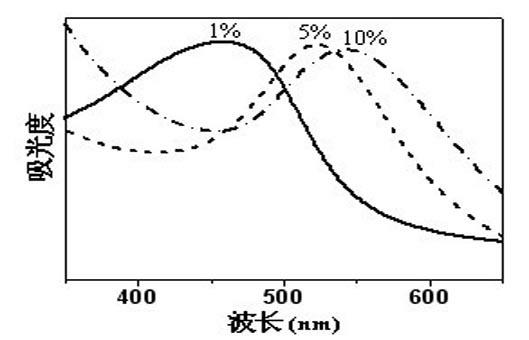

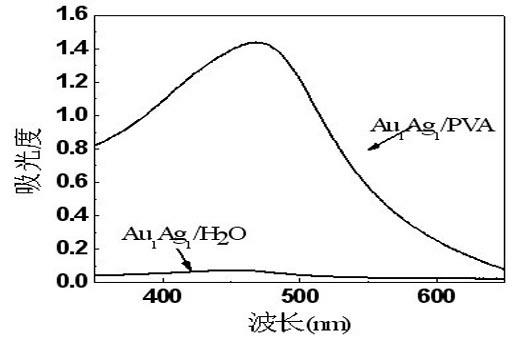

[0027] Three different concentrations of PVA solutions with mass fractions of 1%, 5%, and 10% were prepared as solutions for the reduction of gold-silver alloy nanoparticles. In the PVA solutions of different concentrations, HAuCl 4 (2 mmol, 6 mL) and AgNO 3 (2 mmol, 6 mL), then heated to boiling, and then added 5 mL of sodium citrate solution with a mass concentration of 1% (accounting for 0.3 % of the reaction system), and continued to boil for 2 h to obtain a gold-silver alloy nanoparticle / PVA solution , wherein the gold-silver alloy nanoparticles, the molar ratio of gold and silver is 1:1 (denoted as Au 1 Ag 1 ).

[0028] see atta...

Embodiment 2

[0035] Add 2.4 g of polyvinyl alcohol (PVA) into 13.6 g of water, slowly raise the temperature to 80°C, heat for 1 hour, the PVA is completely dissolved, and the obtained PVA solution is a colorless, transparent and viscous uniform solution. The mass fraction of the PVA solution is 15%.

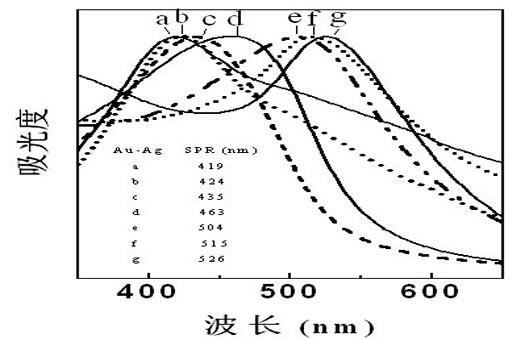

[0036] Add HAuCl configured according to the ratio in Table 1 to the PVA solution with a mass concentration of 1%. 4 (2 mmol) and AgNO 3 (2 mmol), that is, the molar ratios of Au and Ag are 0:1, 1:1, 2:1, 3:1, 1:0; then heated to boiling, and then added 5 mL of 1 % mass concentration Sodium citrate solution (accounting for 0.3% of the reaction system), continued to boil for 2 h to obtain a PVA / Au-Ag nanoparticle solution, and reduced and synthesized alloy nanoparticles with different proportions of Au-Ag, which were successively counted as Ag, Au 1 Ag 1 , Au 2 Ag 1 , Au 3 Ag 1 and Au.

[0037] Table 1

[0038] Nanoparticles HAuCl 4 (2 mmol, mL) AgNO 3 (2 mmol, mL)...

Embodiment 3

[0046] According to embodiment 2 technical scheme, in the PVA solution that mass concentration is 1%, add the HAuCl of configuration simultaneously 4 (2 mmol, 3 mL) and AgNO 3 (2 mmol, 9 mL), then heated to boiling, adding 0.3% sodium citrate solution to the reaction system according to the mass fraction, and continued boiling for 2 h to obtain a colloidal solution of gold-silver alloy nanoparticles, which was reduced to synthesize Au and Ag The molar ratio of alloy nanoparticles is 1:3, counted as Au 1 Ag 3 .

[0047] The prepared Au 1 Ag 3 The alloy nanoparticle colloidal solution was centrifuged three times at 6000 rpm for 25 minutes each time to remove the unreacted metal salt solution; an appropriate amount of 10 wt% PVA solution was added and mixed thoroughly to obtain PVA / Au 1 Ag 3 The PVA concentration in the solution was controlled to be 8 wt%, Au 1 Ag 3 A 4 mmol spinning solution was used for electrospinning.

[0048] A parallel electrospinning device is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com