Method for non-destructively, quickly and accurately characterizing bonding structure of tetrahedral amorphous carbon film

A tetrahedral amorphous carbon and thin film technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of sample damage, sample preparation difficulty, and low characterization accuracy, and achieve no damage to the sample, simple sample preparation, and fast characterization process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

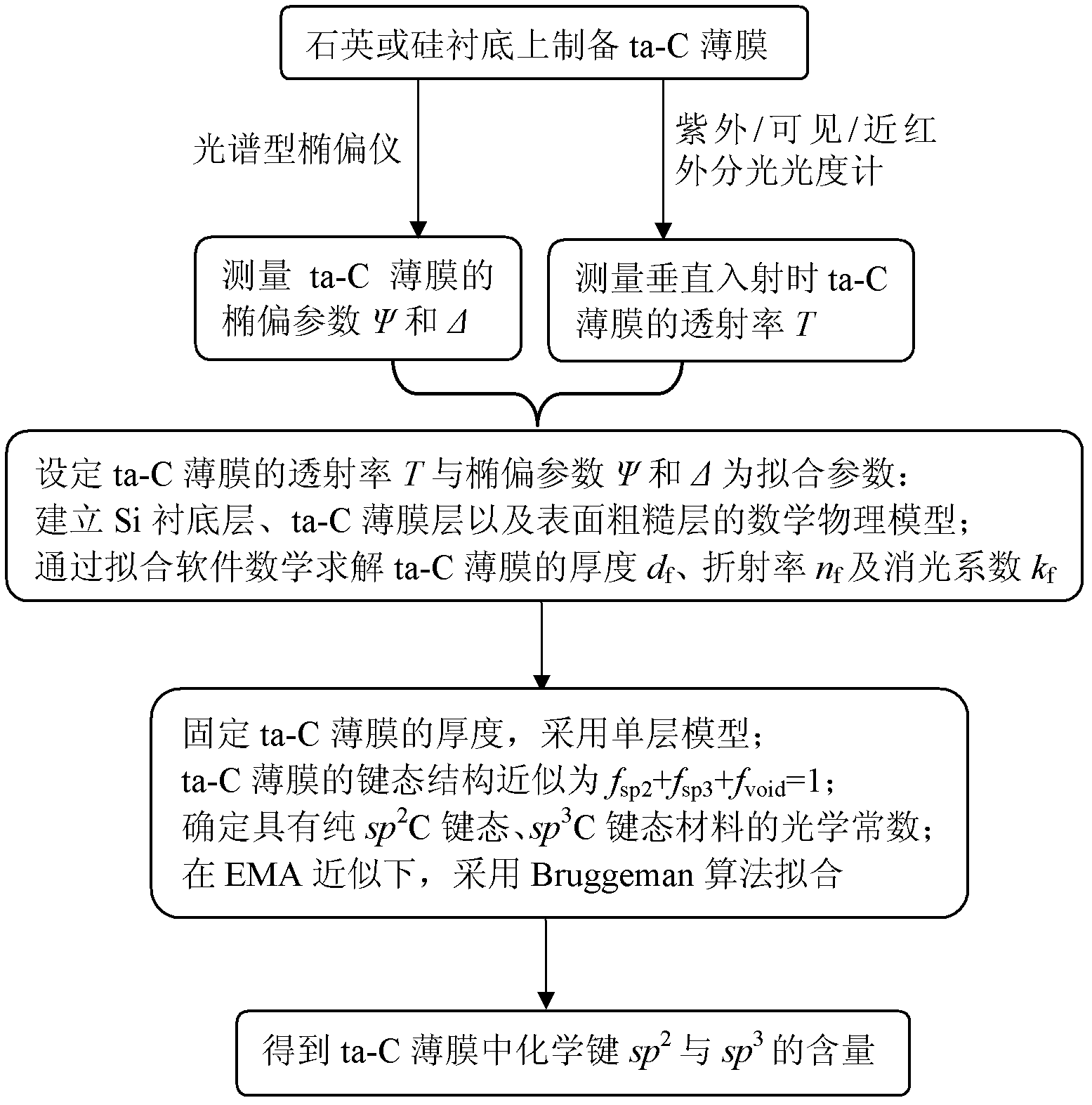

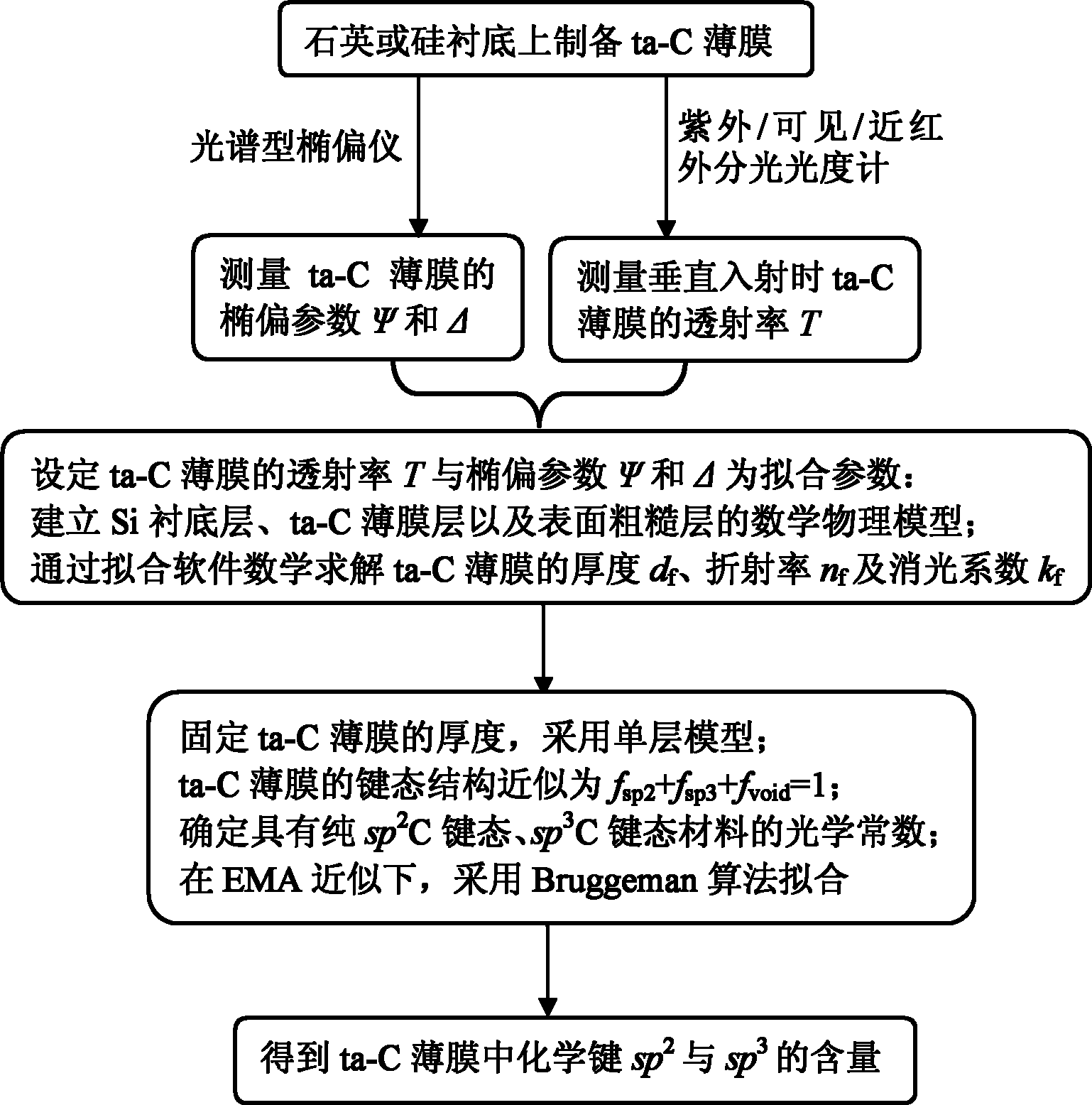

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment 1, sp in the ta-C thin film 2 C bonded state and sp 3 The characterization method of C bond state content is as follows:

[0034] (1) prepare ta-C thin film on quartz or silicon substrate (this preparation process is exactly the same as the preparation process of step (1) in comparative example 1), utilize ultraviolet / visible / near-infrared spectrophotometer to measure after preparation The transmittance T of the ta-C thin film on the substrate at normal incidence, the measurement wavelength is selected as 250-1700nm, and the scanning step is selected as 1nm;

[0035] (2) Start the spectroscopic ellipsometer and initialize it. The spectroscopic ellipsometer includes a sample stage, a vacuum pump, a polarizer, an analyzer and Wvase32 software. The Si substrate of the film is loaded on the sample stage;

[0036] (3) Set the measurement parameters, measure the optical constants of the ta-C film, and select the incident angles of light as 55°, 60° and 6...

Embodiment 2

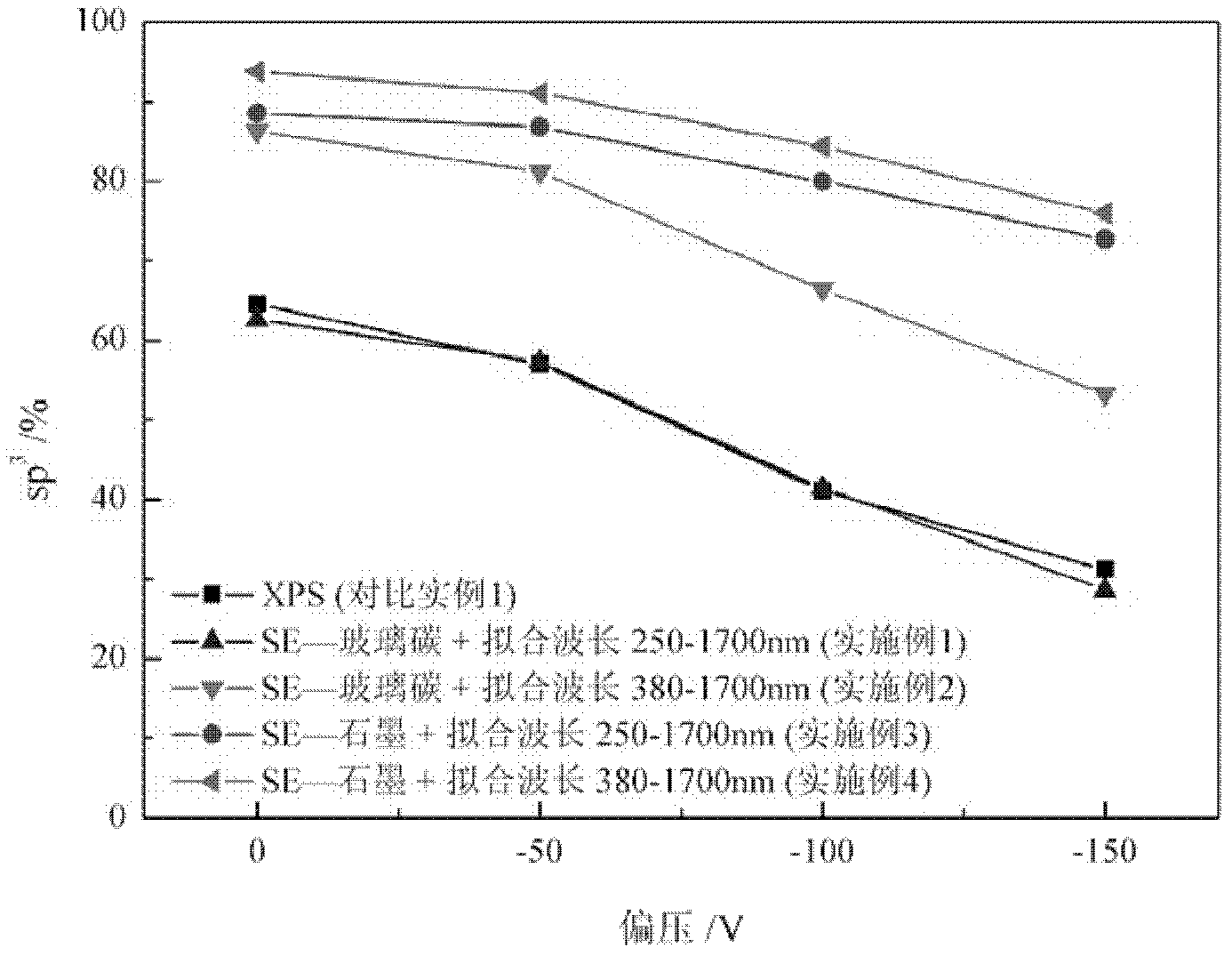

[0042] This embodiment is basically the same as Embodiment 1, the only difference is that in the step (5), the wave band is selected as 380-1700nm, under the EMA approximation, the ta-C thin film is obtained by using the Bruggeman algorithm for fitting chemical bond sp 2 with sp 3 content, where sp 3 content such as figure 2 shown.

Embodiment 3

[0044] The present embodiment is basically the same as embodiment 1, and the only difference is that in the described step (5), the optical constant of graphite is used to represent the pure sp 2 C bond state (ie f sp2 =1) the optical constants of the material, the fitting waveband is selected as 250 ~ 1700nm, under the EMA approximation, by using the Bruggeman algorithm to fit, the chemical bond sp in the ta-C film is obtained 2 with sp 3 content, where sp 3 content such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com