Method for preparing high-power microwave chip type multilayer ceramic dielectric capacitor

A technology of capacitors and microwave chips, which is applied in the direction of laminated capacitors, fixed capacitor electrodes, and parts of fixed capacitors. Layer ceramic capacitors can not wait for the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

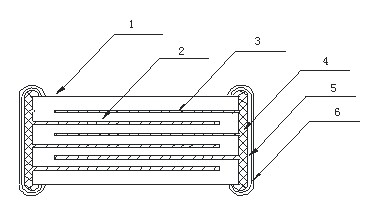

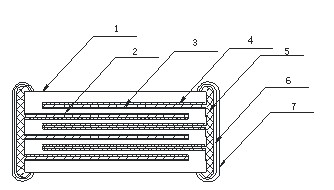

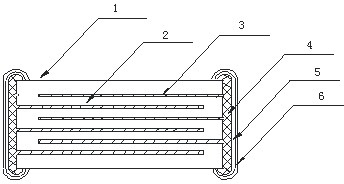

[0042] Such as figure 1 As shown, it consists of multi-layer porcelain dielectric layer, internal electrode layer and three-layer terminal electrode.

[0043] The palladium-silver paste electrode layers on both sides of the ceramic medium are printed in the same pattern, so only one side has a palladium-silver layer at both ends, and each palladium-silver inner electrode layer is electrically connected to the terminal electrode at the end (in this manual) Electrical connection means that there is an electrical connection between two parts, which can be a contact connection, a wire connection, or a conductive connection through other parts).

[0044] From figure 1 It can be seen that the stacked chip multilayer ceramic capacitor has six surfaces, where the surfaces at both ends expose the palladium-silver layer, and a silver electrode layer 4 is provided, and a nickel layer 5 and a tin layer 6 are electroplated on the silver electrode layer 4. , The silver electrode layer 4...

Embodiment 2

[0046] Preparation of a microwave multilayer ceramic capacitor with a working voltage of 500V and a capacitance of 150pF

[0047] a. Put the material-bearing aluminum plate on the base of the medium paste printing machine, and print a layer of 85×85mm on the material-bearing aluminum plate through the non-mark printing method (the size of the hollow non-polyester film is 85×85mm) , a niobium-bismuth-zinc porcelain dielectric slurry film with a thickness of 100 μm, remove the aluminum plate as the material, and dry it in a tunnel oven at 120 ° C for 7 minutes; b. Lower the base of the aluminum plate for the material by 100 μm, repeat the above process After 3 times, an attached piece of the capacitor was formed on the receiving aluminum plate; c. Put the receiving aluminum plate on the base of another printing machine for printing electrodes, and print the product on the surface of the attached sheet. For the electrode paste pattern of 506 capacitors, remove the aluminum plate,...

Embodiment 3

[0050] Preparation of high-power multilayer ceramic capacitors with a working voltage of 1500V and a capacitance of 0.15μF

[0051] a. Put the material-bearing aluminum plate on the base of the medium paste printing machine, and print a layer of 80×80mm on the material-bearing aluminum plate through the non-mark printing method (the size of the hollow non-polyester film is 80×80mm) , a barium titanate porcelain dielectric slurry film with a thickness of 100 μm, remove the aluminum plate as the material, and dry it in a tunnel oven at 130 ° C for 8 minutes; b. Lower the base of the aluminum plate for the material by 100 μm, and repeat the above process After 3 times, an attached sheet of the capacitor was formed on the receiving aluminum plate; c. Put the receiving aluminum plate on the base of another printing machine for printing electrodes, and print 24 electrode paste patterns of capacitors on the surface of the attached sheet, Remove the material-bearing aluminum plate, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com