Preparation method for processing wastewater adsorbing material containing lead

An adsorption material and wastewater technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of high price, large usage, low adsorption rate, etc., and achieve high adsorption selectivity, Effect of extended service life and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

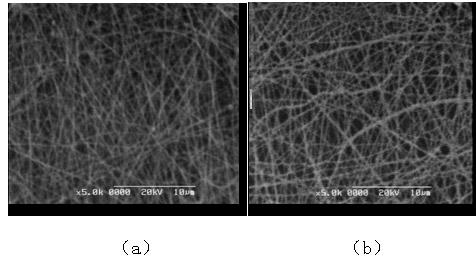

[0030] Weigh 0.66 g of chitosan and 0.10 g of lead chloride with an electronic balance, and dissolve them in a mixed solvent of 20 ml of trifluoroacetic acid and 2 ml of dichloromethane, and magnetically stir for 24 hours to obtain a spinning solution of chitosan. Then add the spinning stock solution to a 20 ml syringe, adjust the flow rate to 0.8 ml / h by a micro syringe pump, use 8 # needle as the spinneret, use aluminum foil as the receiving device, and ground the aluminum foil. The receiving distance between the needle and the aluminum foil is 9 cm, and a voltage of 18 kV is applied for spinning. The nanofiber felt obtained by electrospinning was placed in a closed glass container containing 3 ml of glutaraldehyde, and cross-linked in glutaraldehyde steam at 20°C for 48 hours. The cross-linked chitosan nanofiber mat was washed with 1 mol / L EDTA solution to obtain a lead ion imprinted cross-linked chitosan nanofiber adsorption material.

Embodiment 2

[0032] Weigh 1.00 g of chitosan and 0.10 g of lead nitrate with an electronic balance, and dissolve them in a mixed solvent of 20 ml of trifluoroacetic acid and 2 ml of ioverol, and magnetically stir for 24 hours to obtain a spinning solution of chitosan. Then add the spinning stock solution to a 20 ml syringe, adjust the flow rate to 1.6 ml / h by the micro-injection pump, use the 9 # needle as the spinneret, use the aluminum foil as the receiving device, and the aluminum foil to ground. The receiving distance between the needle and the aluminum foil is 9 cm, and a voltage of 22 kV is applied for spinning. The nanofiber felt obtained by electrospinning was placed in a closed glass container containing 3ml of glyoxal, and cross-linked in glyoxal steam at 30°C for 24 hours. The cross-linked chitosan nanofiber felt was washed with 1 mol / L HCl solution to obtain a lead ion imprinted cross-linked chitosan nanofiber adsorption material.

Embodiment 3

[0034] Weigh 1.32 g of chitosan and 0.16 g of lead chloride with an electronic balance, dissolve them in a mixed solvent of 30 ml of dimethylformamide and 3 ml of dichloromethane, and magnetically stir for 24 hours to obtain a spinning solution of chitosan. Then add the spinning stock solution to a 20 ml syringe, adjust the flow rate to 1.0 ml / h by a micro syringe pump, use a 10 # needle as a spinneret, use aluminum foil as a receiving device, and ground the aluminum foil. The receiving distance between the needle and the aluminum foil is 10 cm, and a 25 kV voltage is applied for spinning. The nanofiber felt obtained by electrospinning was placed in a closed glass container containing 3ml of formaldehyde, and crosslinked in formaldehyde vapor at 40°C for 24h. The cross-linked chitosan nanofiber membrane was washed with 1 mol / L EDTA to obtain a lead ion imprinted cross-linked chitosan nanofiber adsorption material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com