Squarylium cyanine dye sensitized titanium dioxide visible light catalyst, and preparation method and application thereof

A titanium dioxide and dye sensitization technology, applied in the field of photocatalysis, can solve the problems of difficult purification, unfavorable promotion and application, high production cost, and achieve the effects of high photocatalytic activity, simple process and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

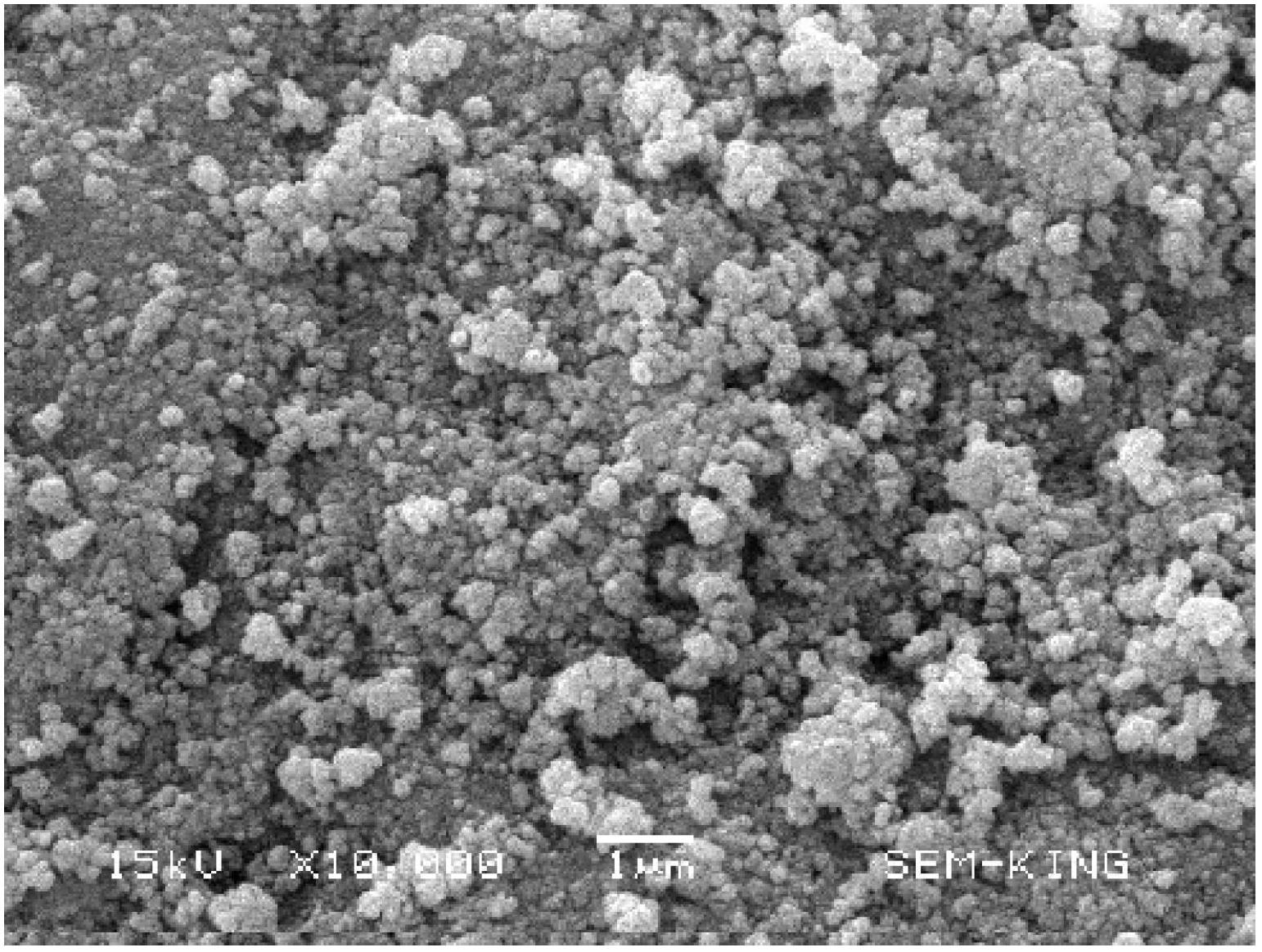

[0026] Mix 15ml of tetrabutyl titanate and 45ml of absolute ethanol to obtain solution A. Take another 32 ml of anhydrous ethanol, adjust the pH to 2~3 with nitric acid, add dropwise to the above-mentioned mixture of tetrabutyl titanate and anhydrous ethanol, stir for 1 hour to mix them thoroughly, and obtain a transparent titanium dioxide sol. After the transparent sol is mixed with 6g of phenol, it is added to the n-heptane dispersion medium, and 8ml of formaldehyde aqueous solution is added dropwise under thorough stirring, and the temperature is raised to 70 ℃ for reaction. After about 1.5 hours, a milky white colloidal liquid is obtained, which is dried at 80 ℃ After calcination at 400℃, titanium dioxide nanoparticles are obtained. The scanning electron micrograph of the nanoparticles is as follows figure 1 Shown.

[0027] The above method was used to prepare nano-titanium dioxide and 2,3,3-trimethyl-3H indole substituted squaraine dye [R 1 H, R 2 Is C(CH 3 ), X is H] and 40...

Embodiment 2

[0029] Substitute the squaraine dye [R] with nano-sized titanium dioxide P25 and 2,3,3-trimethyl-3-ethylindole 1 Is C 2 H 5 ,R 2 Is C(CH 3 ), X is H] and 60ml methanol are added to a single-necked flask, where the mass ratio of nano-titanium dioxide to 2,3,3-trimethyl-3-ethylindole substituted squaraine dye is 100:10, At a temperature of ℃, the mixture was treated with a frequency of 20kHz and an ultrasonic power of 1000W for 0.5 hours, then the methanol solvent was evaporated to dryness, and the solid was dried at 60℃ to obtain 2,3,3-three Methyl-3H indole substituted squaraine dye sensitized titanium dioxide visible light catalyst.

Embodiment 3

[0031] Example 1 prepared nano-titanium dioxide and N-methylbenzothiazole substituted squaraine dye [R 1 For CH 3 ,R 2 Is S, X is H] and 40ml chloroform are added to a single-necked flask, where the mass ratio of nano-titanium dioxide to N-methylbenzothiazole substituted squaraine dye is 100:2, and the mixture is heated at 40℃ The frequency is 30kHz and the ultrasonic power is 500W for 5 hours, then the chloroform solvent is evaporated to dryness, and the obtained solid is dried at 60℃ to obtain N-methylbenzothiazole substituted squaraine dye sensitized Titanium dioxide visible light catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com