Method for preparing microbiologically treated carbon material for supercapacitor

A supercapacitor and microbial treatment technology, applied in chemical instruments and methods, fermentation, inorganic chemistry, etc., can solve problems such as preparing supercapacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

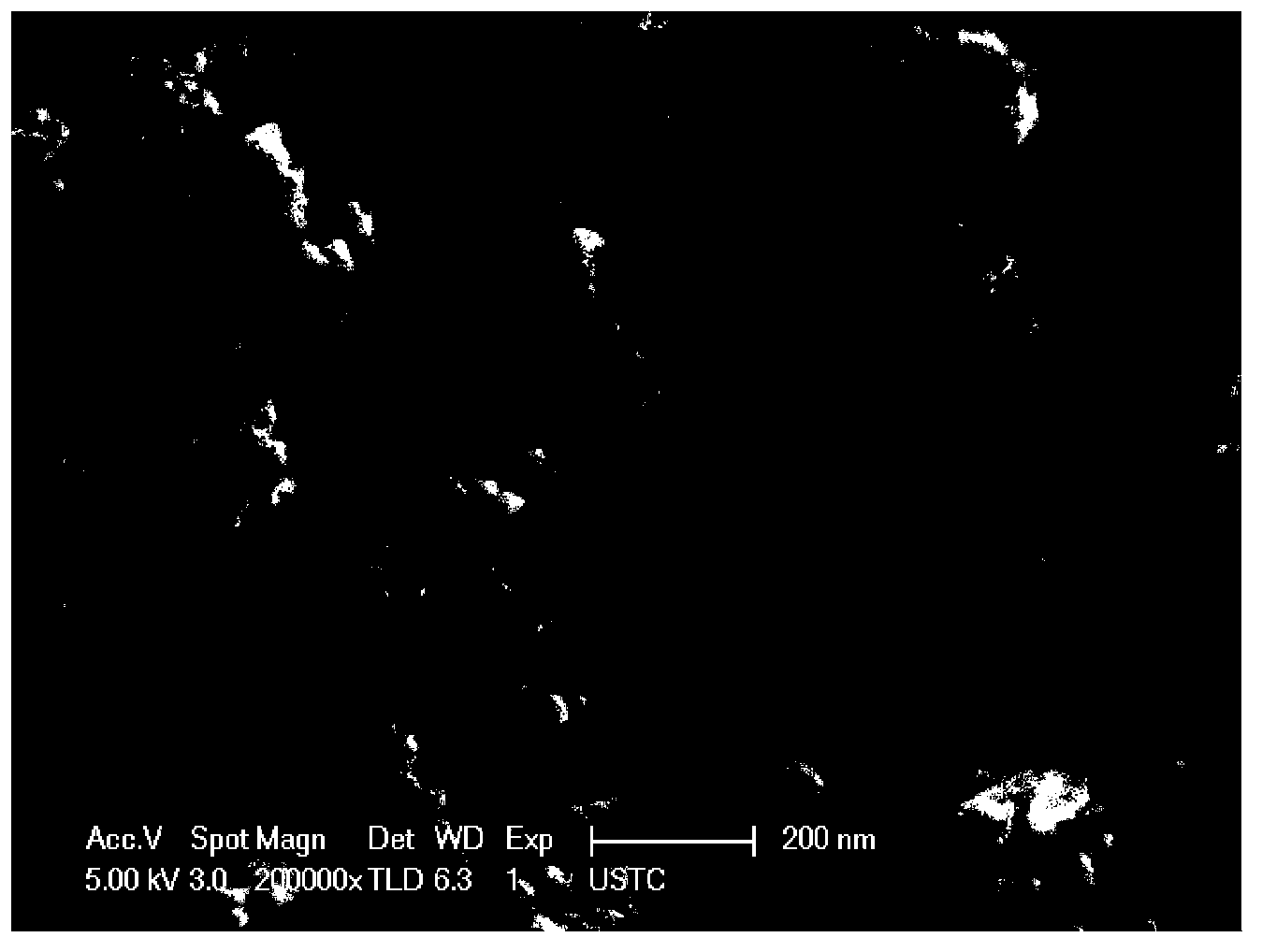

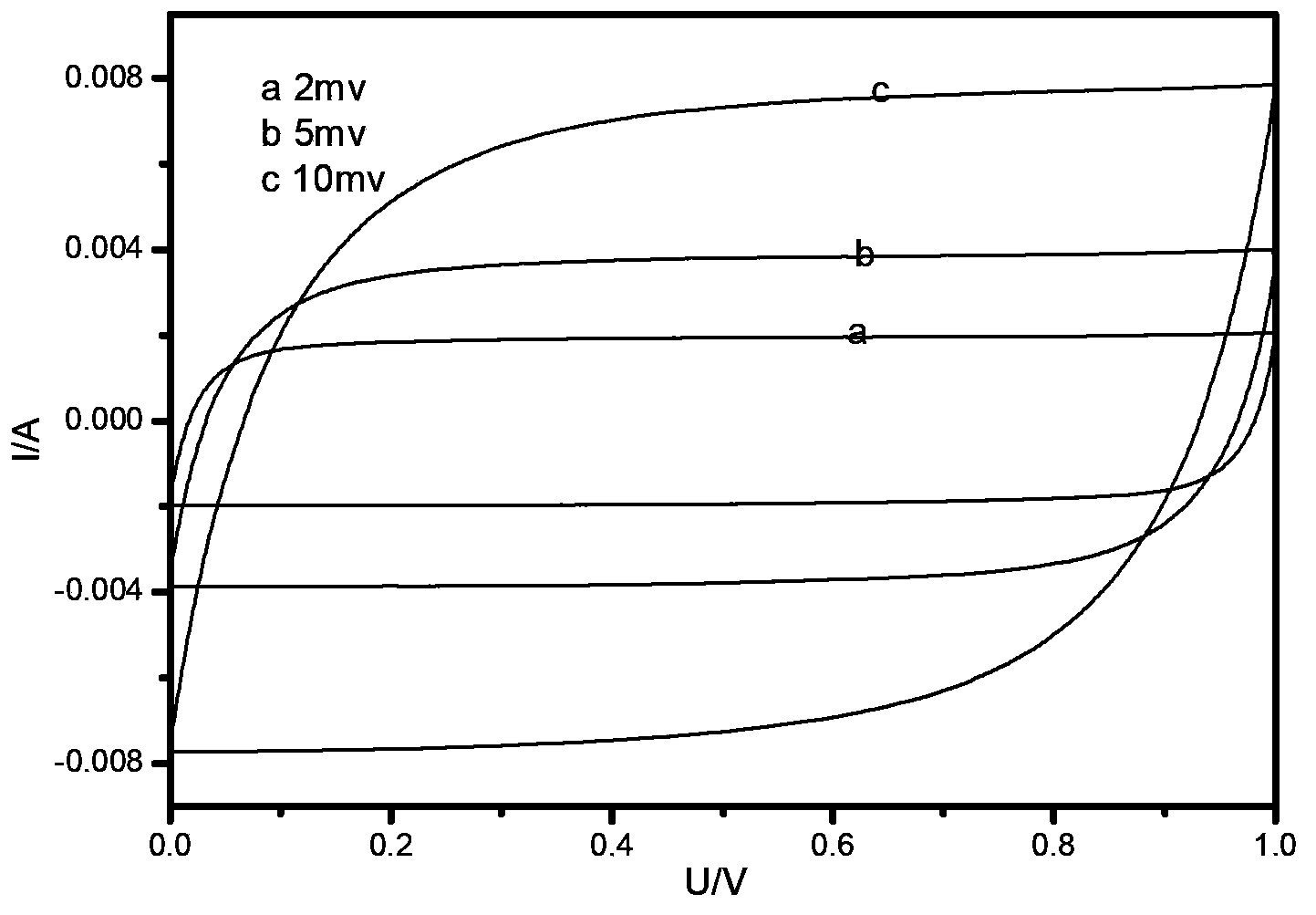

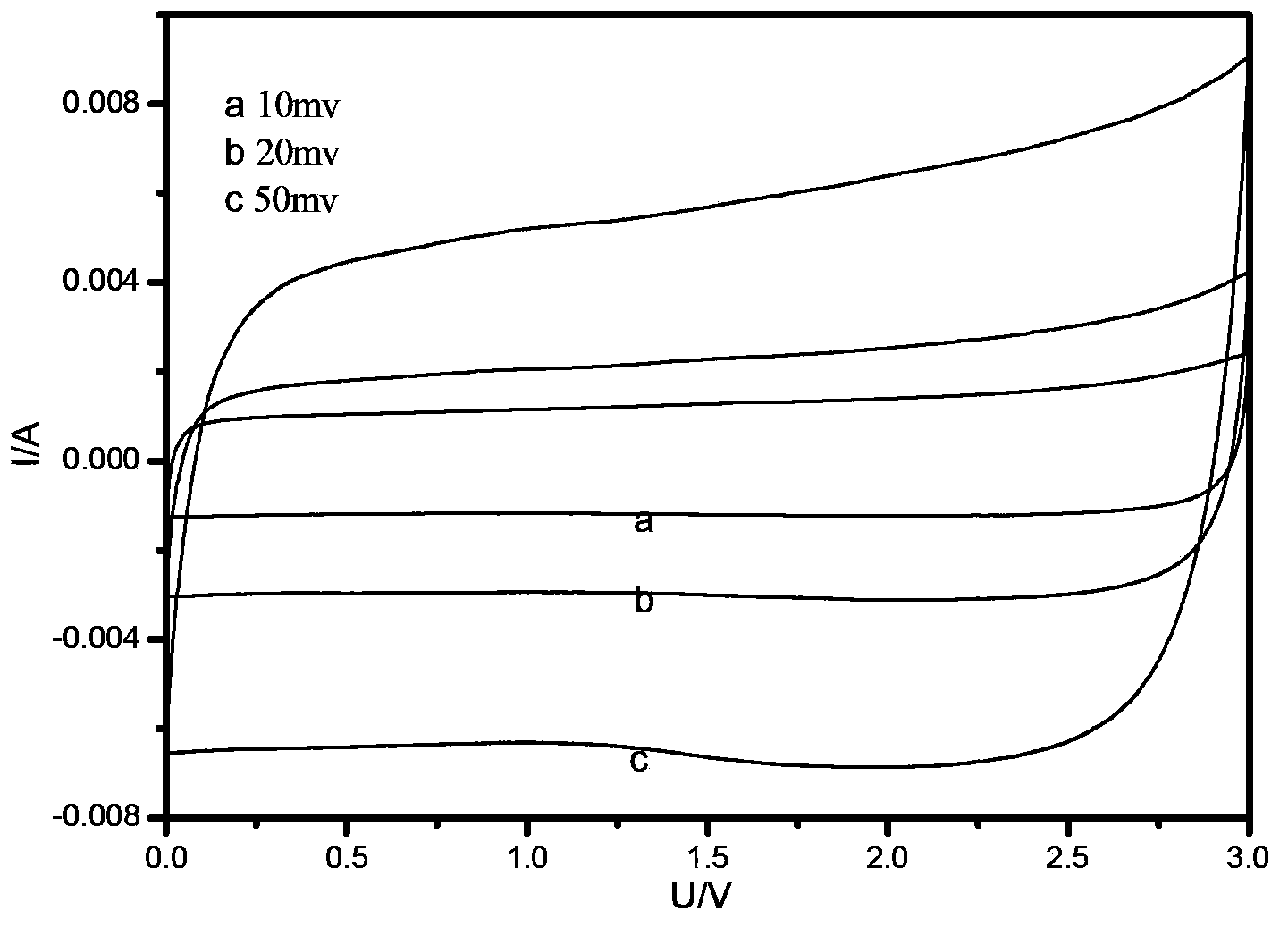

[0028] Weigh 20g of wheat starch and 0.2g of yeast powder, mix them evenly, add water and stir, and ferment at room temperature for 6 hours; place the fermented material in an oven at a temperature of 90°C, and dry it for 20 hours; dry the dried material Put it in a carbonization furnace with a carbonization temperature of 550°C and a carbonization time of 6 hours to obtain a carbonized material; mix the carbonized material with potassium hydroxide at a mass ratio of 1:2, dissolve the potassium hydroxide in water, and mix its aqueous solution with Mix the carbonized material evenly, and then dry it at 100°C; place it in an activation furnace after removing water, the activation temperature is 800°C, and the activation time is 2.5 hours; the activation material is ground to a particle size of 200 mesh, and then washed with water, 6% Wash with hydrochloric acid, then wash with water until the filtrate is clear and the pH reaches about 7; then dry the activated material obtained t...

Embodiment 2

[0033] Weigh 20g of cornstarch and 0.4g of yeast powder, mix them evenly, add water and stir, and ferment at 20°C for 6 hours; put the fermented material in an oven at 150°C, and dry it for 0.5 hours; dry the dried fermented The material is placed in a carbonization furnace, the carbonization temperature is 900°C, and the carbonization time is 0.5 hours to obtain the carbonized material; the carbonized material and potassium hydroxide are mixed in a mass ratio of 1:2, and the potassium hydroxide is dissolved in water, and its aqueous solution is Mix evenly with the carbonized material, then dry at 100°C; place in an activation furnace after removing water, the activation temperature is 500°C, and the activation time is 8 hours; the activation material is ground to a particle size of 100 mesh and then washed with water, 6 % hydrochloric acid, and then washed until the filtrate is clear and the pH reaches about 7; then the activated material obtained by filtration is dried, first...

Embodiment 3

[0036] Weigh 20g of tapioca starch and 0.02g of yeast powder, mix them evenly, add water and stir, and ferment at 25°C for 24 hours; put the fermented material in an oven at 70°C, and dry it for 24 hours; dry the dried fermented The material is placed in a carbonization furnace, the carbonization temperature is 270 ° C, and the carbonization time is 12 hours to obtain the carbonized material; the carbonized material is mixed with potassium hydroxide and sodium hydroxide in a mass ratio of 1:2, potassium hydroxide and hydroxide After the sodium is dissolved in water, mix its aqueous solution with the carbonized material evenly, and then dry it at 100°C; after removing the water, place it in an activation furnace with an activation temperature of 950°C and an activation time of 0.5 hours; grind the activation material to the particle size After being 400 mesh, it was washed with water, washed with 6% hydrochloric acid, and then washed with water until the filtrate was clarified a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com