Gynura bicolor protein extract, and preparation method and application thereof

A protein extract and a protein extraction technology are applied in the field of red phoenix protein extract and its preparation, which can solve the problems of imperfection and no hypoglycemic effect, and achieve the effect of preventing degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

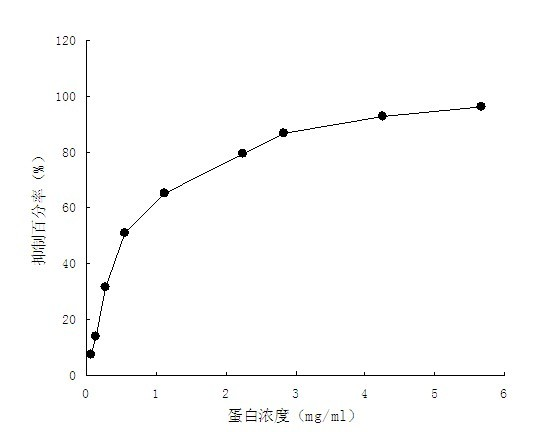

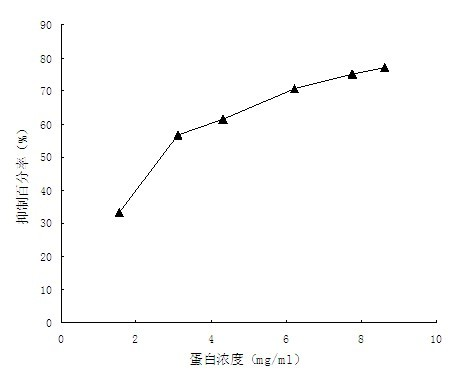

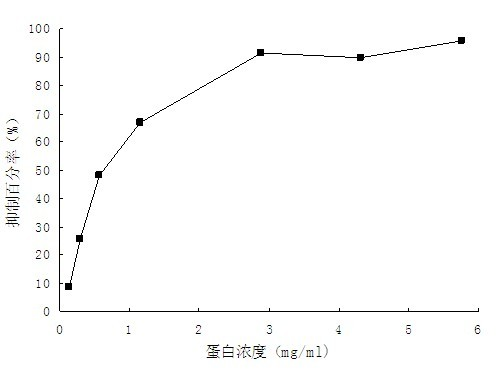

Image

Examples

Embodiment 1

[0024] TCA / acetone method to extract red broccoli protein:

[0025] Weigh 10 g of the penultimate 3-4 fresh leaves of the red phoenix plant, wash them twice with tap water, then wash them once with distilled water, add liquid nitrogen and grind them into fine powder, pour them into a 50 ml centrifuge tube, add 30 ml Add 3ml of trichloroacetic acid (TCA) to ice-cooled acetone at -20°C, vortex and mix well, place the mixture at -20°C for 90 minutes, centrifuge at 4°C (10,000 rpm×20 min), discard the supernatant, The obtained precipitate was washed twice with 30 ml of cold acetone, centrifuged, and the precipitate was taken to dry at room temperature, and 6 ml of extraction buffer (8 mol / L urea, 2 mol / L thiourea, 4% (W / V) CHAPS , 0.4% (V / V) amphoteric carrier buffer (Ampholin pH 3.0-9.5, 50 mmol / L DTT), shake and mix, let stand for 5 minutes, centrifuge at 18°C (10,000 rpm×20 min), and take the supernatant , add 8 ml 10% TCA / cold acetone (containing 20 mmol / L DTT), store at -2...

Embodiment 2

[0028] Tris-HCl buffer extraction / (NH 4 ) 2 SO 4 Precipitation method to extract red broccoli protein:

[0029]Take 20 g of the penultimate 3-4 fresh leaves of the red phoenix plant, add 200 ml of pre-cooled extraction buffer (50 mmol / L Tris-HCl pH 8.5, 0.1 mmol / L PMSF, 1% NaCl), homogenate, Extract at 4°C for 20 min, centrifuge (10,000 rpm×15 min), take the supernatant, add (NH 4 ) 2 SO 4 Make the saturation up to 80%, place it at 4°C for 20 min, then centrifuge (10,000 rpm×15 min), and the resulting precipitate is the protein of 0-80% saturation of red phoenix. Add an appropriate amount of 50 mmol / L Tris-HCl (pH 8.5) to the precipitate, and after complete dissolution, put the protein solution into a dialysis bag for dialysis to remove residual (NH 4 ) 2 SO 4 and finally freeze-drying the protein solution to prepare the freeze-dried powder of the red broccoli protein extract.

[0030] 1.55 g sample was obtained by this method, and the protein content was 49.4% by Kj...

Embodiment 3

[0032] Tris-HCl buffer extraction / (NH 4 ) 2 SO 4 Fractional precipitation method to extract red broccoli protein:

[0033] Take 20g of the penultimate 3-4 fresh leaves of the red phoenix plant, add pre-cooled extraction buffer (50 mmol / L Tris-HCl pH 8.5, 0.1 mmol / L PMSF, 1% PVP, 2 mmol / L EDTA-Na 2 , 20 mmol / L DTT, 10 mmol / L Vc, 1% NaCl) 200ml, homogenate, extract at 4°C for 20min, filter through 2 layers of gauze, take the filtrate and centrifuge (10,000 rpm×15min), get the supernatant, and put it on the Added to the supernatant (NH 4 ) 2 SO 4 Make the saturation up to 20%, put it at 4°C for 10min, and then centrifuge (4°C, 10,000 rpm×15min), the obtained precipitate is the protein of 0-20% saturation of the extracted Chinese cabbage; take the supernatant, add (NH 4 ) 2 SO 4 Make the saturation reach 50%, place it at 4°C for 10 minutes, and then centrifuge (4°C, 10,000 rpm×15 min), the obtained precipitate is the protein of 20-50% saturation of the extracted Chinese c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com