Anion exchange membrane based on ionic liquid crosslinking agent and preparation method of anion exchange membrane

A technology of anion exchange membrane and ionic liquid, which is applied in the field of anion exchange membrane based on ionic liquid crosslinking agent and its preparation, can solve the problems of poor chemical stability, achieve good thermal stability, improve electrical conductivity and mechanical properties, and avoid The effect of the use of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

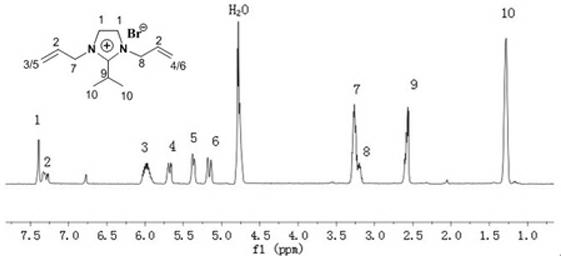

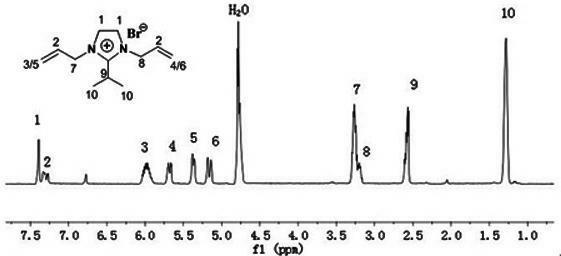

[0028] Ionic Liquid Crosslinker Preparation of:

[0029] Under nitrogen protection, 6.05g (0.05mol) allyl bromide, 4.05g (0.05mol) 2-methylimidazole, 0.05g hydroquinone and 5.61g (0.10mol) were added to a three-necked flask with 40ml of acetonitrile ) KOH stirred at room temperature for 4 hours, filtered and rotary evaporated to obtain the crude product, the crude product was dissolved in chloroform, extracted with water, the chloroform layer was taken, anhydrous magnesium sulfate was added to remove water, and the product 2-methyl-1 was obtained by rotary evaporation Allylimidazole 5.3 g (87% yield).

[0030] Under nitrogen protection, add 2-methyl-1 allyl imidazole 3.05g (0.025mol), allyl bromide 3.03g (0.025mol), 0.03g hydroquinone and 20ml ethyl acetate in the three-necked flask, React at room temperature for 48 hours, the reactant was washed 3 times with ethyl acetate, and vacuum-dried at room temperature for 24 hours. 6.60 g of the final product (yield 92%) was obtain...

Embodiment 2

[0032] 0.2g, acrylonitrile 0.2g, styrene 0.1g, 0.01g, divinylbenzene 0.02g, mix the solution evenly, apply it on the mold, irradiate with ultraviolet light (wavelength 240nm-380nm) for 30min, and polymerize in situ to form a film. The anion exchange membrane was then soaked in 1M KOH solution at 60°C for 24 hours to convert anions into OH - , the OH obtained in this example - The ion conductivity of the type anion exchange membrane at room temperature is 1.6×10 -2 S cm -1 , the ionic conductivity at 90°C is 4.53×10 -2 S cm -1 . The tensile strength is 9.23 Mpa, the Young's modulus is 421.34 Mpa, and the elongation at break is 61.34%.

Embodiment 3

[0034] 0.2g, acrylonitrile 0.3g, 0.01g, divinylbenzene 0.02g, mix the solution evenly, apply it on the mold, irradiate with ultraviolet light (wavelength 240nm-380nm) for 30min, and polymerize in situ to form a film. The anion exchange membrane was then soaked in 1M KOH solution at 50°C for 24 hours to convert anions into OH - , the OH obtained in this example - The ion conductivity of the type anion exchange membrane at room temperature is 1.8×10 -2 S cm -1 , the ionic conductivity at 90°C is 5.03×10 -2 S cm -1 . The tensile strength is 8.76 Mpa, the Young's modulus is 391.53Mpa, and the elongation at break is 68.12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com