Peracetic acid in single-ingredient disinfection solution and preparation method thereof

A technology of monobasic peracetic acid and disinfectant, applied in the field of disinfectant and monobasic peracetic acid disinfectant, can solve the problems of complex production technology, high production cost, strong corrosiveness, etc., and achieves simple production process and high production safety. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

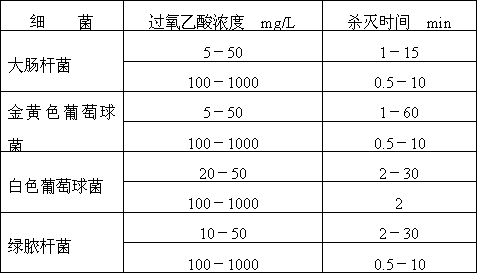

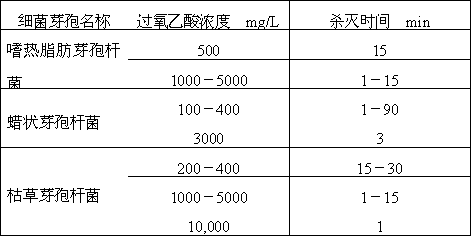

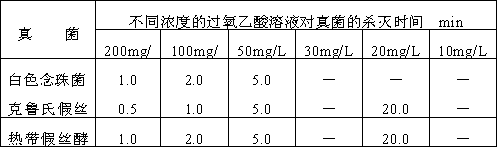

Image

Examples

Embodiment 1

[0022] A monobasic peracetic acid disinfectant, composed of the following raw materials in weight percentage: 25% hydrogen peroxide; 35% acetic acid; 0.01% HWP comprehensive cooperative stabilization system based on polyhydroxy polycarboxylate multi-ligand structure compound; special block Nonionic surfactant 0.15%. Among them, the HWP comprehensive cooperative stabilization system is a polyhydroxy polycarboxy multi-coordination system formed by the condensation reaction of ethylenediaminetetraacetic acid and 2-phosphonobutane-1,2,4-tricarboxylic acid in a molar ratio of 1:1. body complex; wherein the special block nonionic surfactant is a C6 fatty alcohol-initiated ethylene oxide / propylene oxide block copolymer, wherein the molecular weight of the ethylene oxide / propylene oxide block copolymer is 10000; the rest is water.

[0023]The preparation method includes the following steps in sequence: 1) Weigh the nitrogen-containing compound and the phosphorus-containing compound i...

Embodiment 2

[0025] A monobasic peracetic acid disinfectant, composed of the following raw materials in weight percentage: 30% hydrogen peroxide; 35% acetic acid; 1% HWP comprehensive cooperative stabilization system based on polyhydroxy polycarboxylate multi-ligand structure complex; special block Nonionic surfactant 0.55%. Among them, the HWP comprehensive cooperative stabilization system is a polyhydroxy polycarboxylate multi-ligand complex formed after the condensation reaction of hydroxyethyl ethylenediamine triacetic acid and ethylenediamine tetramethylene phosphonic acid in a molar ratio of 1:1; The special block nonionic surfactant is an ethylene oxide / propylene oxide block copolymer initiated by C9 isomeric decanyl alcohol, wherein the molecular weight of the ethylene oxide / propylene oxide block copolymer is 12000; The rest is water.

[0026] The preparation method includes the following steps in sequence: 1) Weigh the nitrogen-containing compound and the phosphorus-containing co...

Embodiment 3

[0028] A monobasic peracetic acid disinfectant, composed of the following raw materials in weight percentage: 35% hydrogen peroxide; 25% acetic acid; 1.5% HWP comprehensive cooperative stabilization system based on polyhydroxy polycarboxylate multi-ligand structure compound; special block Non-ionic surfactant 0.01%, among which the HWP comprehensive cooperative stabilization system is a polyhydroxy polycarboxylate formed by the condensation reaction of hydroxypropyl ethylenediamine triacetic acid and diethylene triamine pentamethylene phosphonic acid in a molar ratio of 1:1 Multi-ligand complex; wherein the special block nonionic surfactant is an ethylene oxide / propylene oxide block copolymer initiated by C12 isomeric tridecanyl alcohol, wherein ethylene oxide / propylene oxide The molecular weight of the block copolymer is 12000; the remainder is water.

[0029] The preparation method includes the following steps in sequence: 1) Weigh the nitrogen-containing compound and the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com