Preparation method of graphene/nanometer particle composite materials based on infrared ray radiation

A nanoparticle and composite material technology, applied in the field of graphene/nanoparticle composite material preparation, can solve difficult reduction processing, uncontrollable size and thickness of graphene sheets, difficult to meet large area or large amount of graphite oxide reduction requirements, etc. problem, to achieve the effect of low production cost, favorable for popularization and utilization, and short heating and cooling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

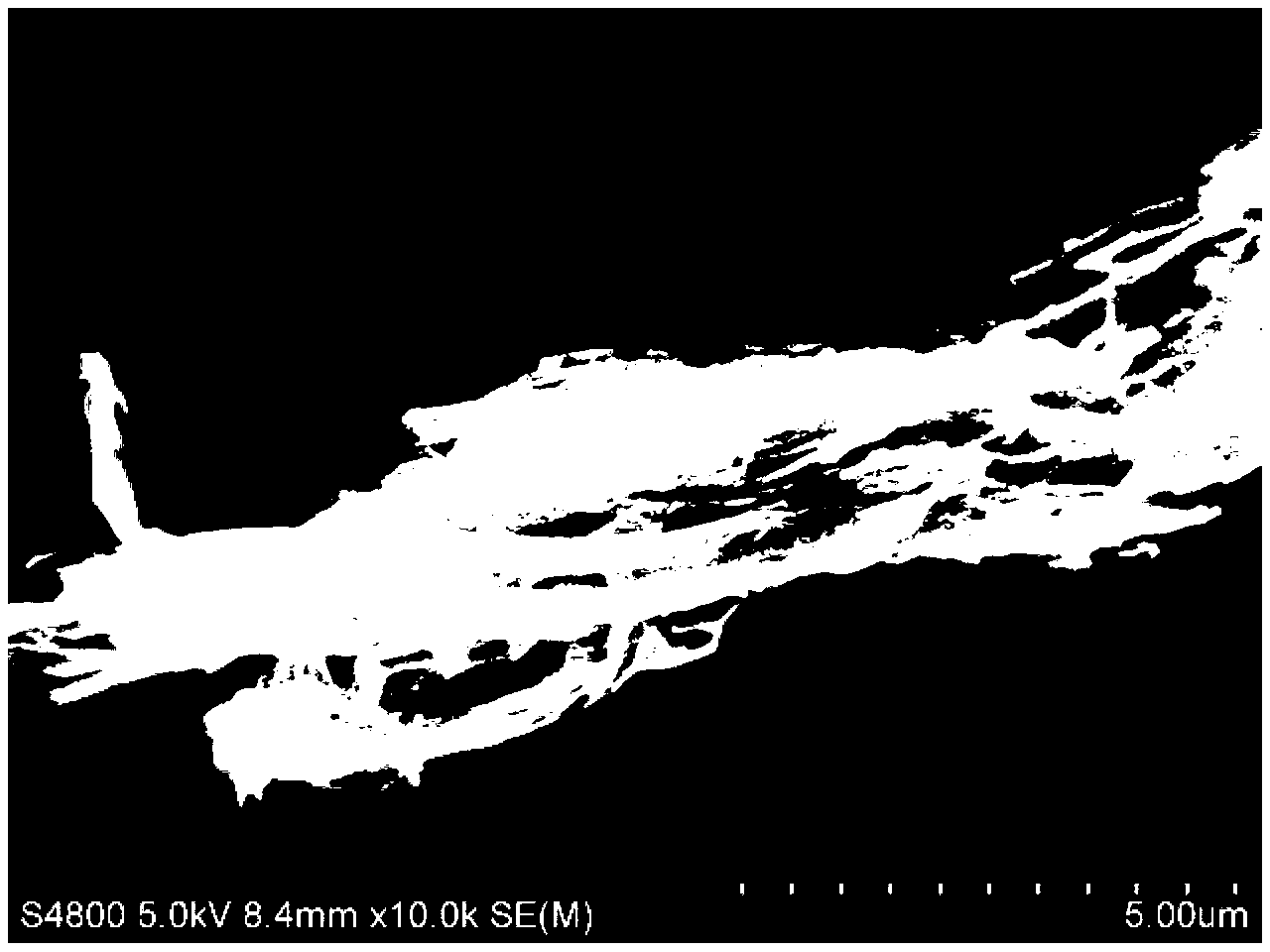

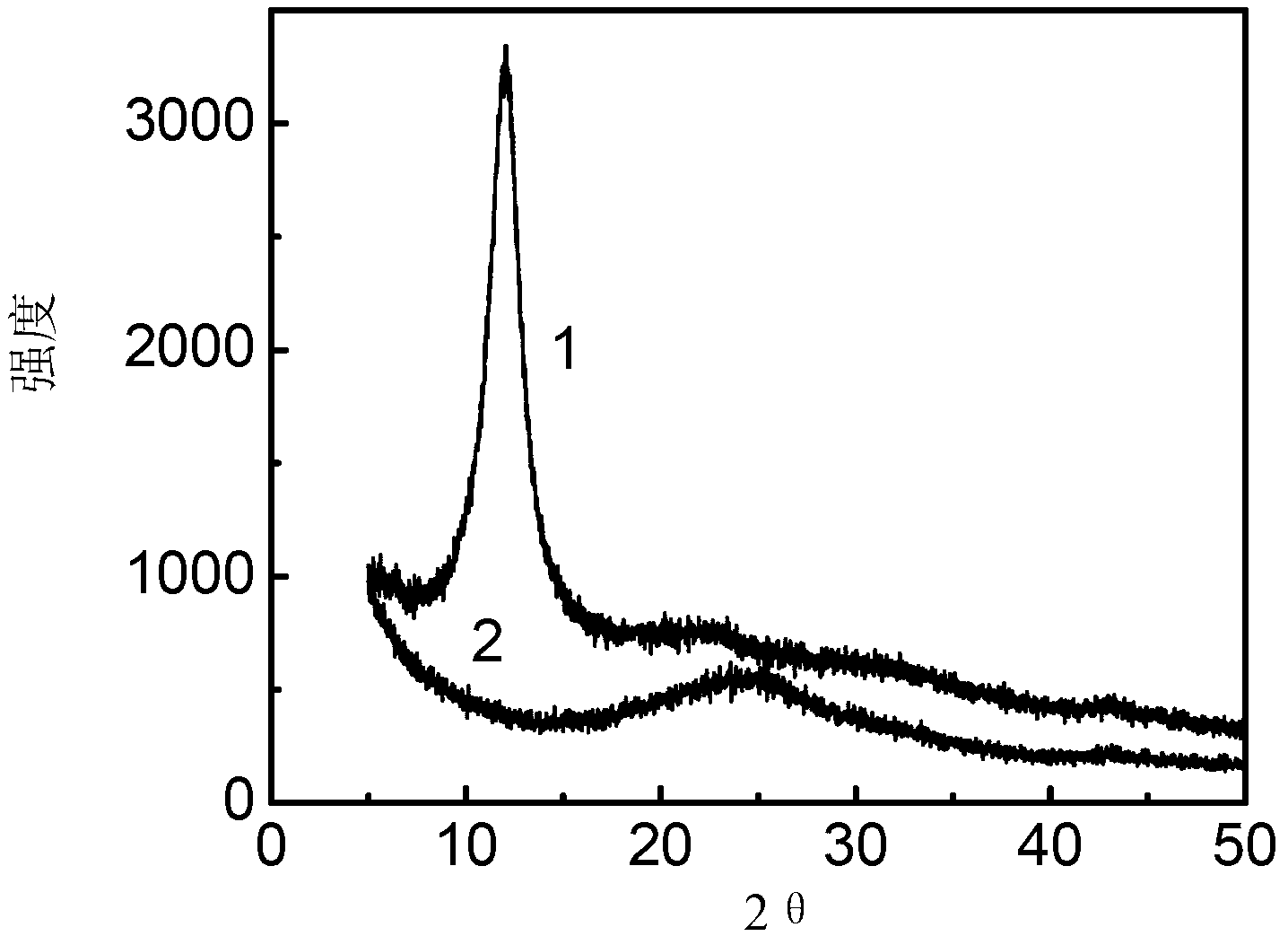

[0031] React 3g of graphite, 3g of sodium nitrate, 60mL of concentrated sulfuric acid (98%) and 6g of potassium permanganate at 35°C for 2 hours, then add 100mL of deionized water, and then add hydrogen peroxide with a weight percentage of 3%. Hydrogen oxide aqueous solution 200mL, pickling and water washing after standing for 12 hours to obtain graphite oxide jelly. The graphite oxide jelly was vacuum-dried or freeze-dried at a room temperature of 25° C. to obtain a solid graphite oxide. Use an infrared heating lamp with a power of 275W to irradiate it at a distance of 10 mm from the graphite oxide solid for 1 minute, and a reduction reaction occurs to obtain a reduced graphite oxide solid. Scanning electron micrographs of reduced graphite oxide solids as figure 1 As shown, it can be seen that the structure of the reduced graphite oxide obtained under this condition is loose and porous, indicating that the reduction process is relatively violent and a large amount of gas is ...

Embodiment 2

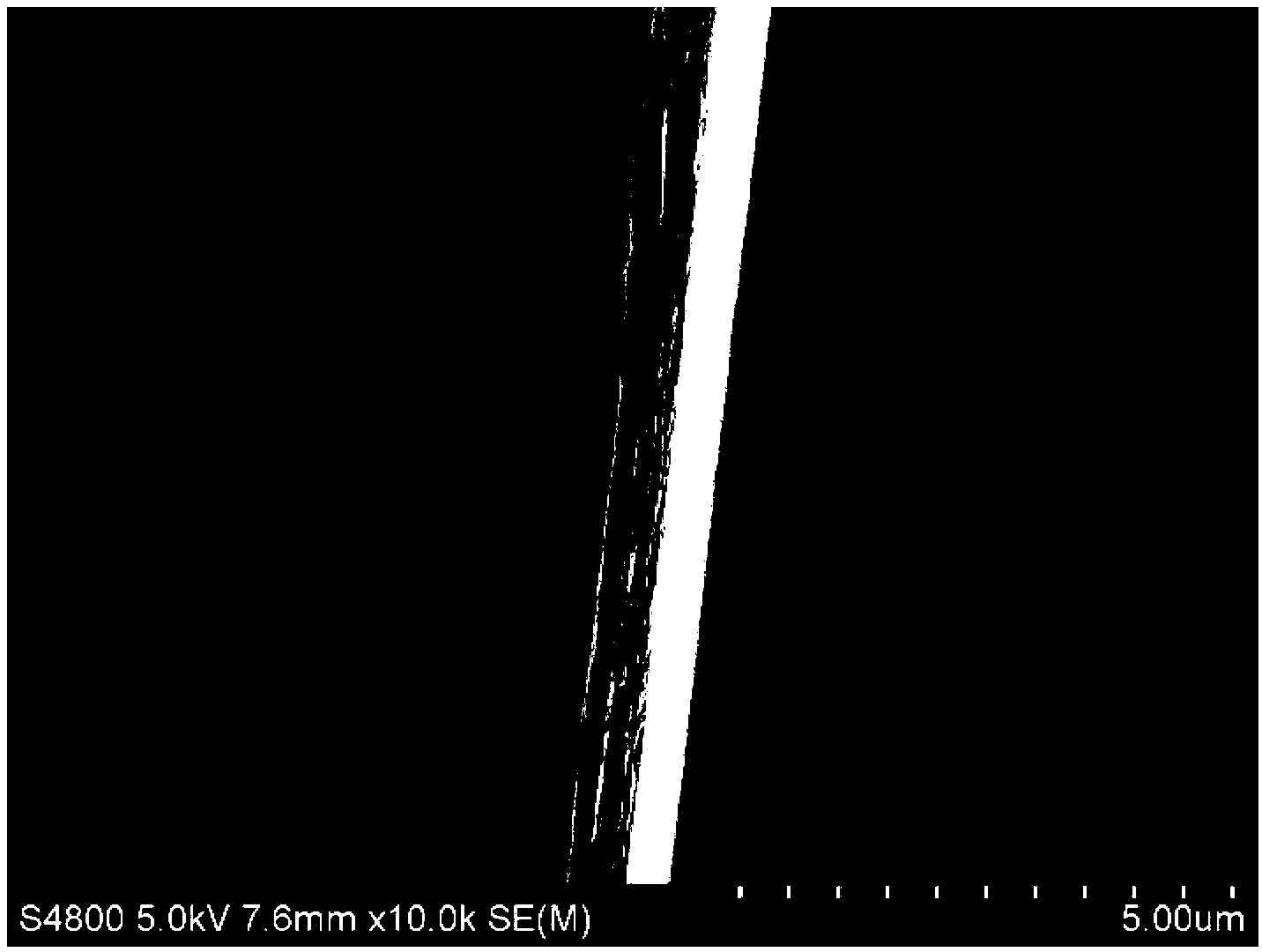

[0034] The graphite oxide jelly prepared in Example 1 was diluted with water to a weight percentage of graphite oxide of 0.01%, and then spin-coated on the glass surface to form a film of graphite oxide. After heating and drying at 70°C, the water content was reduced to 5%, and then an infrared heating lamp with a power of 275W was irradiated at a distance of 200 mm from the graphite oxide film for 60 minutes to obtain a reduced graphite oxide film. Scanning electron micrographs of the cross-section of the reduced graphite oxide film image 3 As shown, uniform and non-porous reduced graphite oxide films can be obtained under this condition.

Embodiment 3

[0036] 1) Mix 200 parts of an aqueous suspension of graphite oxide with a weight percent of graphite oxide of 0.5% and 10 parts of an aqueous suspension of silicon nanoparticles with a weight percent of silicon nanoparticles of 1%, and the silicon nanoparticles The diameter of the particles is 40nm~60nm, and the mixed solution is obtained after stirring evenly. The mixed solution is poured into the sample tank, and dried in an oven at 70°C for 2 hours until the weight percentage of the total solvent is equal to 46%, and graphite oxide is obtained. / composite of silicon nanoparticles;

[0037] 2) Use an infrared heating lamp with a power of 275W to irradiate it at a distance of 100 mm from the composite of graphite oxide / silicon nanoparticles in step 1) for 60 minutes to obtain 0.6 parts of reduced graphite oxide / silicon nanoparticles composite material ( That is, graphene / silicon nanoparticle composite material), its volume resistivity is 150Ω·cm, and its conductivity is exce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com