A kind of preparation method of flower-shaped molybdenum disulfide hollow microspheres

A technology of molybdenum disulfide and hollow microspheres, which is applied in the direction of molybdenum sulfide and nanotechnology, can solve the problems that the shape of molybdenum disulfide hollow microspheres is difficult to control, the nanoparticles are easy to agglomerate, and affect the large-scale application. The effect of simple and easy to control, obvious layered structure, high specific surface area and tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 0.2g C 13 h 22 Dissolve ClN in 70ml of distilled water, then add 1.40g CS(NH 2 ) 2 , 0.725gNH 2 OH·HCl and 0.88g (NH 4 ) 2 MoO 4 . After completely dissolving, use 2mol·L -1 Adjust the pH to around 6 with HCl. After stirring for 30 min, the mixture was transferred to a 100 ml stainless steel reaction kettle, placed in a vacuum drying oven at 180° C. for 24 h, and cooled to room temperature. After the reaction product was separated by centrifugation, it was repeatedly washed with deionized water and absolute ethanol, and finally dried at 80°C for 10 h under vacuum to obtain a gray-black product powder, namely flower-shaped molybdenum disulfide hollow microspheres.

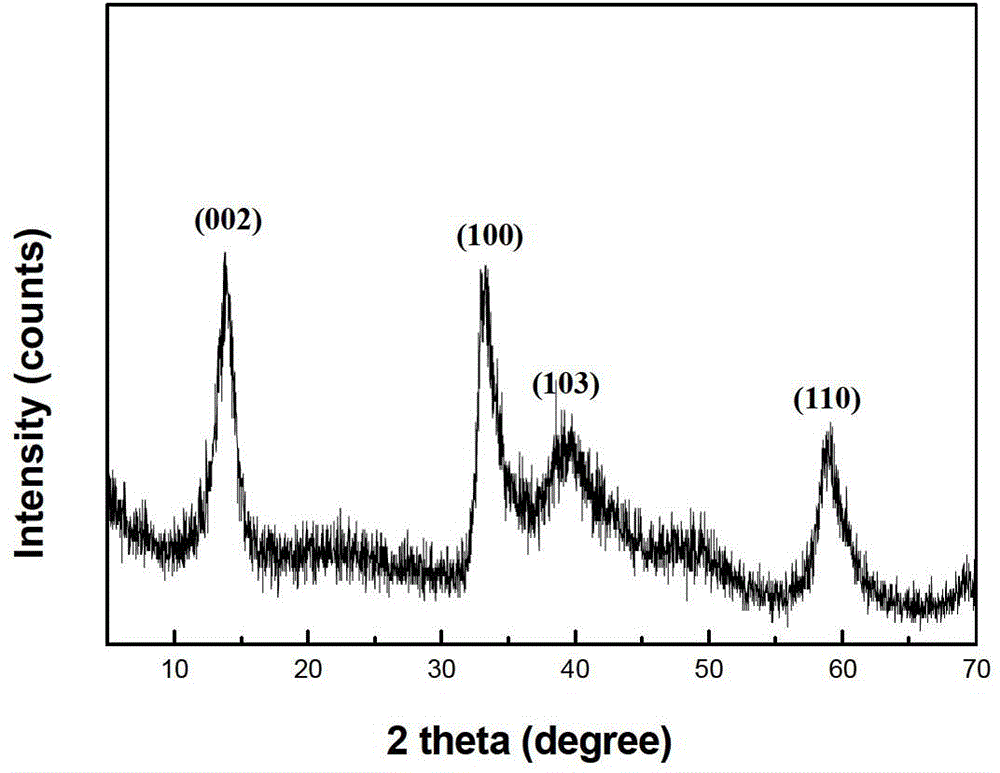

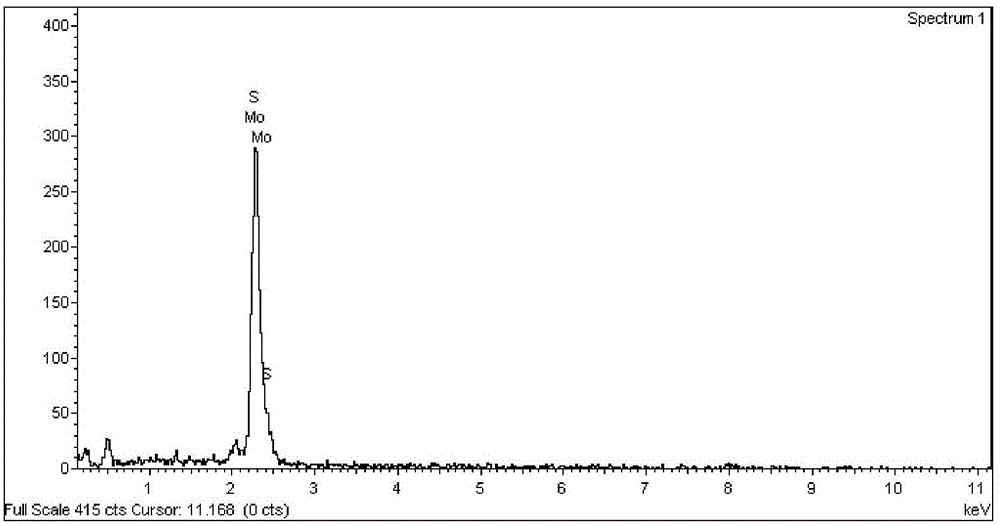

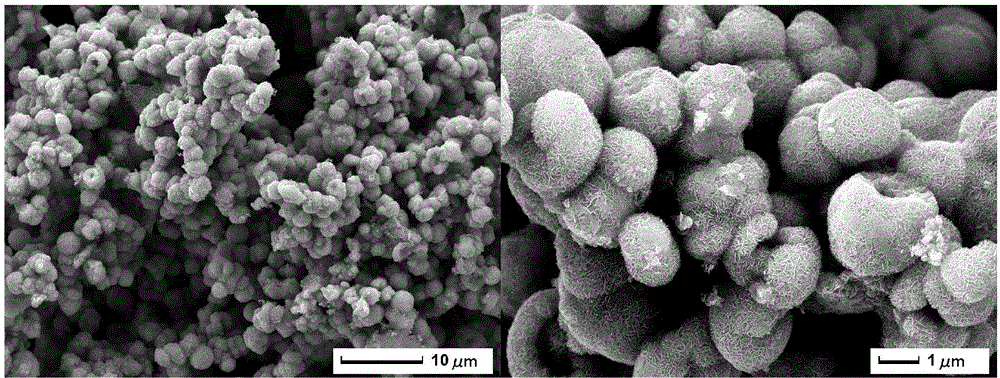

[0042] figure 1 It is a flower-like molybdenum disulfide hollow microsphere XRD pattern, all diffraction peaks are consistent with pure MoS 2 The crystal standard diffraction pattern (PDF No.37-1492) of the hexagonal phase is consistent. Therefore, nanoscale MoS should be synthesized by hydrotherm...

Embodiment 2

[0044] Dissolve 13.6g of F127 in 70ml of distilled water, then add 1.40g of CS(NH 2 ) 2 , 0.725gNH 2 OH·HCl and 0.88g (NH 4 ) 2 MoO 4 . After completely dissolving, use 2mol·L -1 Adjust the pH to around 6 with HCl. After stirring for 30 min, the mixture was transferred to a 100 ml stainless steel reaction kettle, placed in a vacuum drying oven at 180° C. for 24 h, and cooled to room temperature. After the reaction product was separated by centrifugation, it was repeatedly washed with deionized water and absolute ethanol, and finally dried at 80°C for 10 h under vacuum to obtain a gray-black product powder, namely flower-shaped molybdenum disulfide hollow microspheres.

Embodiment 3

[0046] 0.383g (C 8 h 17 ) 2 (CH 3 ) 2 NCl was dissolved in 60ml of distilled water, and then 2.28g of CS (NH 2 ) 2 , 1.45g NH 2 OH·HCl and 1.01g (NH 4 ) 2 MoO 4 . After completely dissolving, use 2mol·L -1 Adjust the pH to around 5 with HCl. After stirring for 20 min, the mixture was transferred to a 100 ml stainless steel reaction kettle, placed in a vacuum oven at 140° C. for 30 h, and cooled to room temperature. After the reaction product was separated by filtration, it was repeatedly washed with deionized water and absolute ethanol, and air-dried to obtain a gray-black product powder, that is, flower-shaped molybdenum disulfide hollow microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com