Method and device for processing ship ballast water by applying advanced electro catalysis oxidation

A technology for ship ballast water and advanced oxidation, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc. It can solve the problem of carcinogenic chloroform, microbial methods that cannot meet the requirements, and secondary environmental pollution, etc. problem, to achieve the effect of fast response, reduced energy consumption, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

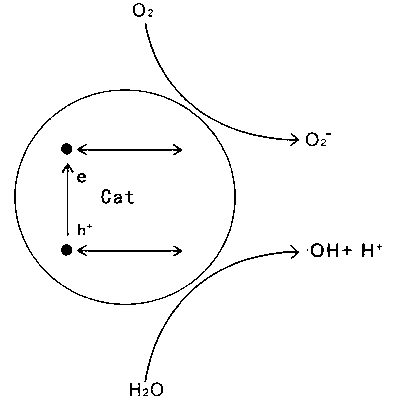

[0048] A method for electrocatalytic advanced oxidation treatment of ship ballast water, the process is as follows: using special catalytic electrode materials, through electrocatalytic advanced oxidation in the ballast water body, high concentration of hydroxyl radicals are generated under micro current density, The hydroxyl radicals react biochemically with the microorganisms in the ballast water, causing oxidative stress damage to the microorganisms in the ballast water, thereby terminating their life. The biochemical reaction refers to the lipid peroxidation between the hydroxyl radicals and the microorganisms in the ballast water. , amino acid oxidative decomposition, protein conformation changes, DNA oxidation and cytochrome decolorization and other biochemical processes.

[0049] Such as figure 1 As shown, the special semiconductor catalytic electrode produces a "hole" effect under the action of an electric field, that is, when the special semiconductor catalytic elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com