Method for synthesizing fluorine halogenated ether

A synthesis method and fluorohalogenated ether technology, applied in the direction of ether preparation, etc., can solve the problems of long reaction time, harsh reaction conditions, difficult storage, etc., and achieve the effects of stable product quality, low reaction pressure and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

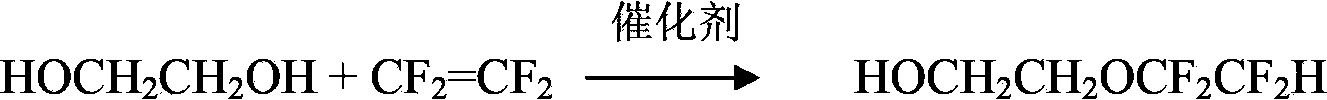

Image

Examples

Embodiment 1

[0031] Add 800g of ethylene glycol, 600g of sulfolane, and 40g of potassium hydroxide into a 2L stainless steel autoclave with mechanical stirring. After the raw materials are added, close the feeding port and replace the gas in the kettle with high-purity nitrogen. When the oxygen content in the kettle is less than 50ppm, start stirring, and feed tetrafluoroethylene through the gas mass flow meter until the pressure in the kettle reaches 0.8MPa. Raise the temperature to 60°C to start the reaction, continuously feed tetrafluoroethylene during the reaction, keep the reaction pressure at 0.8-0.9MPa, and control the reaction temperature at 60-65°C. After feeding 400g of tetrafluoroethylene, stop passing through tetrafluoroethylene, cool, discharge, and rectify to obtain 492g of 2-(1,1,2,2-tetrafluoroethoxy)ethanol, 2-(1,1,2, The purity of 2-tetrafluoroethoxy)ethanol is 99.6%. Yield 75.0%.

[0032] In a 500ml four-neck flask with mechanical stirring and a reflux condenser, add 2...

Embodiment 2

[0034] Add 800g of ethylene glycol, 400g of N,N-methylformamide, and 80g of sodium hydroxide into a 2L stainless steel autoclave with mechanical stirring. After the oxygen content in the kettle is less than 50ppm, start stirring, and feed tetrafluoroethylene through the gas mass flowmeter until the pressure in the kettle reaches 0.5MPa, then raise the temperature to 10°C to start the reaction, and continuously feed tetrafluoroethylene during the reaction process to make the reaction The pressure is kept at 0.5-0.6 MPa, and the reaction temperature is controlled at 10-20°C. After feeding 200g of tetrafluoroethylene, stop passing through tetrafluoroethylene. Cool, discharge, and rectify to obtain 259g of 2-(1,1,2,2-tetrafluoroethoxy)ethanol with a purity of 99.2% and a yield of 79.9%.

[0035]In a 500ml four-neck flask with mechanical stirring and a reflux condenser, add 250g of 2-(1,1,2,2-tetrafluoroethoxy)ethanol prepared by the above method, stir, and cool the flask with an ...

Embodiment 3

[0037] Add 400g ethylene glycol, 1200g sulfolane, and 80g potassium hydroxide to a 2L stainless steel autoclave with mechanical stirring. After the raw materials are added, close the feeding port and replace the gas in the kettle with high-purity nitrogen. When the oxygen content in the kettle is less than 50ppm, start stirring, and feed tetrafluoroethylene through the gas mass flow meter until the pressure in the kettle reaches 1.0MPa. Raise the temperature to 90°C to start the reaction, continuously feed tetrafluoroethylene during the reaction, keep the reaction pressure at 1.0-1.1MPa, and control the reaction temperature at 90-95°C. After feeding 100g of tetrafluoroethylene, stop passing through tetrafluoroethylene, cool, discharge, and rectify to obtain 129g of 2-(1,1,2,2-tetrafluoroethoxy)ethanol, with a purity of 99.5% and a yield of 79.6% .

[0038] In a 500ml four-necked flask with mechanical stirring and a reflux condenser, add 125g of 2-(1,1,2,2-tetrafluoroethoxy)et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com