Segmented copolymer type dispersing agent and photo-initiation polymerization preparation method thereof

A technology of block copolymer and photo-initiated polymerization, which is applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., and can solve the problems of difficulty in adapting to grinding and dispersing environments, weak resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

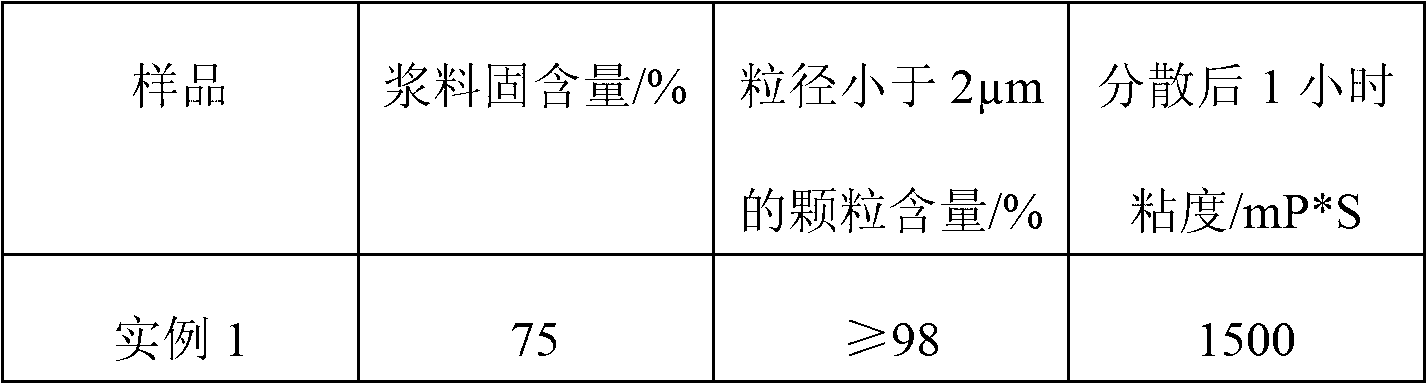

Embodiment 1

[0028] Preparation of low molecular weight narrow distribution poly(acrylic acid-b-vinyl alcohol) sodium salt:

[0029] Add CuCl to the reaction kettle 2 7.2g, add 300.20g of xylene after sufficient nitrogen to expel oxygen, stir and mix, continue to pass nitrogen for 30 minutes, then add 16.74g of 2,2′-bipyridine, raise the temperature to 50°C under the protection of nitrogen and react for 1 hour to obtain a uniform complex solution.

[0030] Raise the temperature to 100°C, turn on the ultraviolet lamp to irradiate the reaction kettle, add dropwise the mixture of tert-butyl acrylate monomer (30g) and benzophenone (4g), the dropwise addition time is 30 minutes, and keep the constant temperature for 30 minutes after the dropwise addition is completed. Then stop the UV light irradiation.

[0031] At the same temperature, add 250.10 g of tert-butyl acrylate monomer, react for 5 hours, add 31 g of vinyl acetate, and react for 3 hours to obtain block copolymer poly(tert-butyl acr...

Embodiment 2

[0034] Preparation of low molecular weight narrow distribution poly(methacrylic acid-b-vinyl alcohol) sodium salt:

[0035] Add CuBr to the reactor 2 16.02g, add 350.20g of xylene after sufficient nitrogen to drive oxygen, stir and mix, continue to pass nitrogen for 30 minutes, then add 22.50g of 2,2′-bipyridine, raise the temperature to 50°C under the protection of nitrogen and react for 1 hour to obtain a uniform complex solution.

[0036] Raise the temperature to 120°C, turn on the UV lamp to irradiate the reactor, add the mixture of vinyl acetate monomer (20.11g) and benzophenone (6.02g) dropwise for 30 minutes, and react at constant temperature for 30 minutes after the addition is completed , and then stop the UV light irradiation.

[0037] At the same temperature, 15.10 g of vinyl acetate monomer was added and reacted at constant temperature for 2 hours. Add 350 g of tert-butyl methacrylate and react at constant temperature for 5 hours to obtain a block copolymer poly...

Embodiment 3

[0040] Preparation of low molecular weight narrow distribution poly(acrylic acid-co-methacrylic acid-b-vinyl alcohol) sodium salt:

[0041] Add CuCl to the reaction kettle 210.02g, add 350.15g of xylene after sufficient nitrogen to drive away oxygen, stir and mix, continue to pass nitrogen for 30 minutes, then add 23.50g of 2,2′-bipyridine, heat up to 50°C under nitrogen protection, and react for 1 hour to obtain a uniform complex solution.

[0042] Raise the temperature to 105°C, turn on the UV lamp to irradiate the reactor, and add tert-butyl acrylate monomer (12g), tert-butyl methacrylate (13.5g) and benzophenone (7.05g) dropwise through nitrogen to drive oxygen The mixture was added dropwise for 30 minutes. After the dropwise addition was completed, the reaction was carried out at a constant temperature for 30 minutes, and then the ultraviolet light irradiation was stopped.

[0043] At the same temperature, tert-butyl acrylate monomer (132 g) and tert-butyl methacrylate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com