Surface modification process for low-dielectric material

A low-dielectric material and surface modification technology, applied in the direction of inorganic chemistry, non-metallic elements, silicon compounds, etc., can solve the problems of affecting the electrical properties of materials, difficult to ensure the uniformity of impurities, and the deviation of dielectric constant, so as to reduce water absorption Sexuality, low cost, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

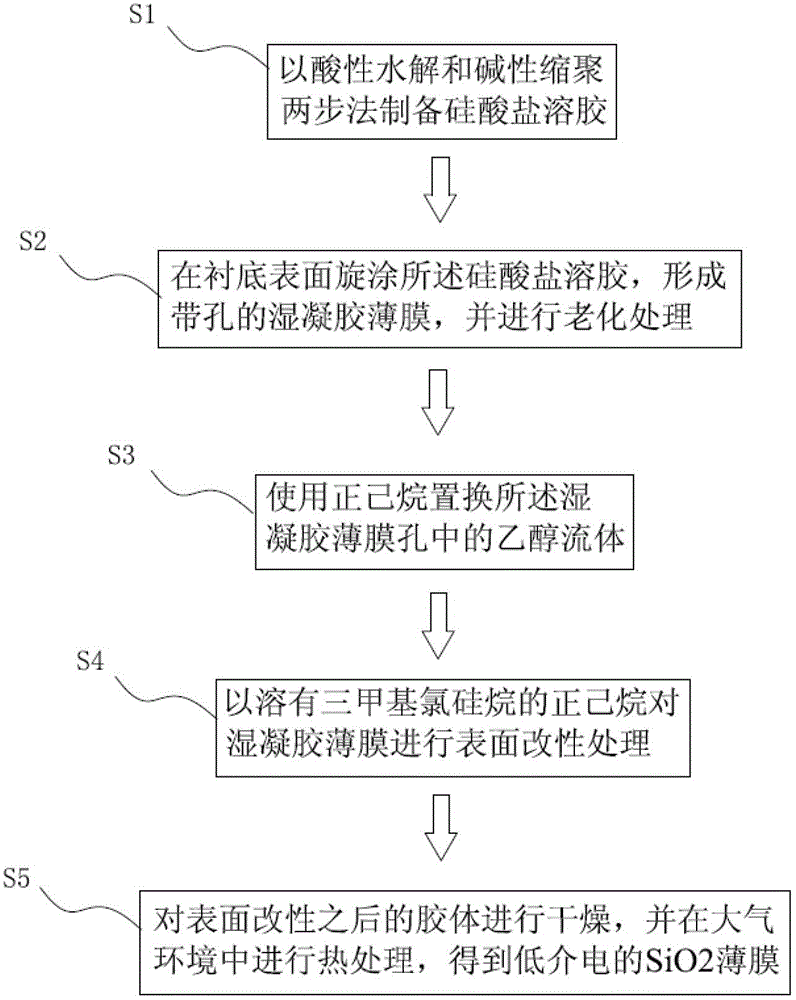

[0045] Mix ethyl silicate (TEOS), ethanol, water and hydrochloric acid in a molar ratio of 1:3:1:1.4×10 -4 Proportional preparation of standard solutions.

[0046] Take ten milliliters of the standard solution, add 2ml of 0.05M / L ammonia solution and 14ml of ethanol, stir for 110 minutes, and when the viscosity coefficient is 8-14cP, spin-coat in an atmosphere of ethanol at a speed of 2000 rpm Minutes, 18 seconds; then place the sample in an atmosphere filled with ethanol for aging treatment, and the temperature is room temperature.

[0047] Replace the ethanol fluid in the pores of the wet gel film with n-hexane.

[0048] The n-hexane solution containing trimethylchlorosilane with a volume fraction of 6% was used to modify the surface of the film, and the sample was immersed in the n-hexane solution at 60°C for 12 hours;

[0049] The sample was heated to 300°C at a rate of 1°C / min, kept for 2 hours, and cooled at a rate of 2°C / min, and the entire heat treatment process was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com