Up-and-down-conversion luminescent high-transmittance amorphous fluoride film and preparation method thereof

A fluoride and thin film technology, applied in the field of high-transparency amorphous fluoride thin film and its preparation, can solve problems such as low transmittance, achieve the effects of high transmittance, improve photoelectric conversion efficiency, and reduce light reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

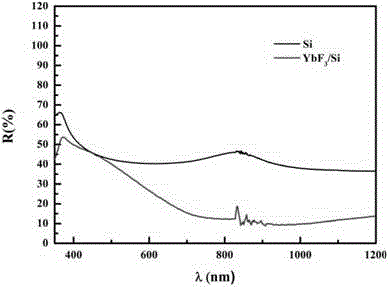

[0032] (1) In YbF 3 Add ErF to the powder 3 Powder, where ErF 3 The mole fraction of the powder is 5%, then ball milled and mixed, dried and pressed into tablets, and calcined at 600°C for 8 hours by carbon coating to make a ceramic target. The XRD pattern of its ceramic target material (see figure 1 ) basically conforms to YbF 3 PDF 34-0102 Diffraction Standard Spectrum.

[0033] (2) YbF prepared by the above method 3 : Er ceramic target material, using electron beam deposition method: using silicon wafer as the substrate, under vacuum conditions, the substrate temperature is 500°C, the target distance is 32cm, the deposition beam current is 4, and the deposition time is 15min to obtain YbF 3 film.

Embodiment 2

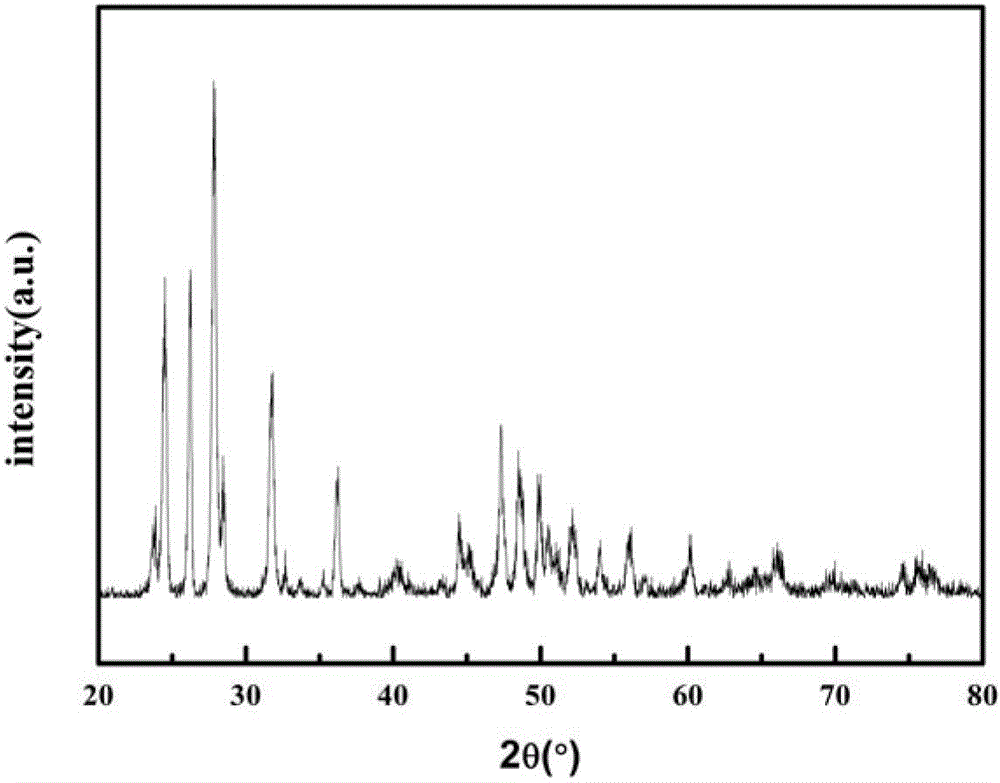

[0035] (1) In YbF 3 Add ErF to the powder 3 Powder, where ErF 3 The mole fraction of the powder is 5%, and then ball milled and mixed, dried and pressed into tablets, and calcined at 650°C for 8 hours by carbon coating, and fired into a ceramic target.

[0036] (2) YbF prepared by the above method 3 : Er ceramic target material, using electron beam deposition method: using silicon wafer as the substrate, under vacuum conditions, the substrate temperature is 500 ℃, the target distance is 32cm, the deposition beam current is 3, and the deposition time is 60min to obtain YbF 3 film, its XRD pattern is shown in figure 2 .

Embodiment 3

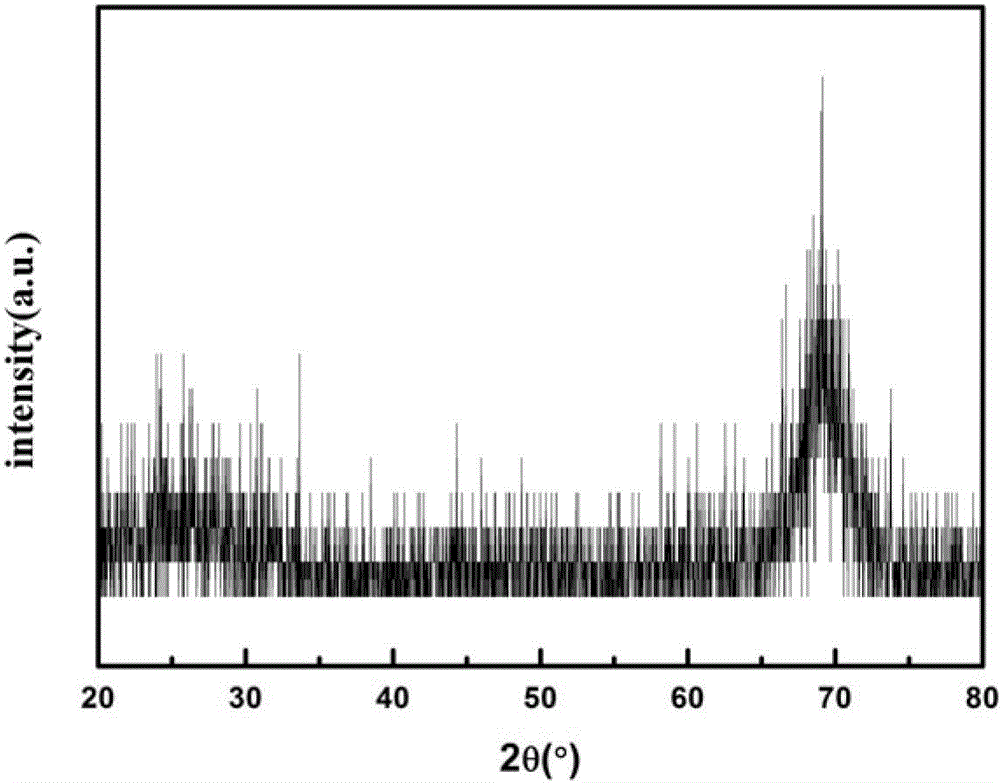

[0038] (1) In YbF 3 Add ErF to the powder 3 Powder, where ErF 3 The mole fraction of the powder is 10%, then ball milled and mixed, dried and pressed into tablets, and calcined at 750°C for 8 hours by carbon coating to make a ceramic target. Its XRD pattern is shown in image 3 .

[0039] (2) YbF prepared by the above method 3 : Er ceramic target material, using the electron beam deposition method: using a silicon wafer as the substrate, under vacuum conditions, the substrate temperature is 500°C, the target distance is 32cm, the deposition beam current is 5, and the deposition time is 60min to obtain YbF 3 film, its XRD pattern is shown in Figure 4 . Use the FLS920 fluorescence spectrometer to measure the emission spectrum at room temperature under the excitation condition of 378nm. For the emission spectrum, see Figure 5 ; For the luminescence spectrum excited at 980nm see Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com