Integrated preparation method for LED fluorescent powder coating

A phosphor and coating technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as electrode pattern separation, and achieve the effect of improving optics and overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

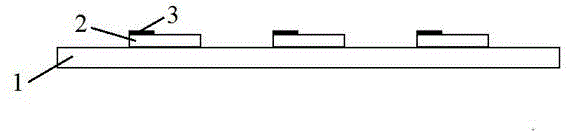

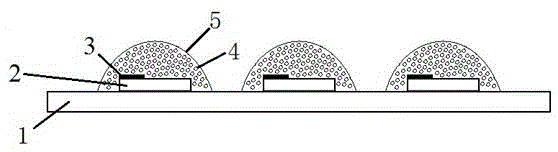

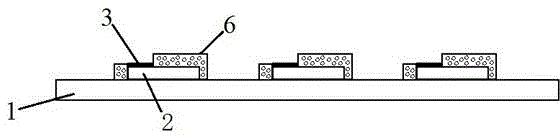

Image

Examples

Embodiment 1

[0072] Take polyvinyl alcohol (PVA), photosensitive agent ammonium dichromate (ADC), phosphor powder and deionized water and mix evenly to form a stable powder PVA dispersion containing phosphor particles. The phosphor powder photosensitive adhesive dispersion is coated on the surface of the LED chip (Wafer, wafer) by the overmolding method, and the required coating thickness is controlled.

[0073] Air-dried or oven-dried, exposed with an external light source (blue light or ultraviolet light) combined with a mask plate, developed with hot water, and obtained a phosphor powder photosensitive adhesive dispersion coating pattern on the surface of the LED chip in the light-emitting direction.

[0074] Put the LED chip with the coating pattern of phosphor photosensitive adhesive dispersion into the plasma degumming equipment, and use the method of oxygen plasma bombardment to remove the organic components in the coating to obtain a powder layer containing phosphor particles.

[0...

Embodiment 2

[0078]Mix polyvinyl alcohol (PVA), diazo resin, phosphor powder and deionized water in a certain proportion (2%: 0.02%: 17.98%: 80%) to form a stable dispersion of diazo photosensitive adhesive containing phosphor particles body.

[0079] Spinning is used to coat the phosphor powder photosensitive adhesive dispersion on the surface of the LED chip (wafer) to control the coating requirements of a certain thickness.

[0080] Air-dried or oven-dried, exposed with an ultraviolet or blue light source combined with a mask plate, and then developed with hot water to obtain a phosphor powder photosensitive adhesive dispersion coating pattern on the surface of the LED chip in the light-emitting direction.

[0081] Put the LED chip (Wafer) with the photosensitive adhesive pattern of the phosphor into the plasma degumming equipment, and use the method of argon / hydrogen (85 / 15) plasma bombardment to remove the organic components in the photosensitive adhesive, and obtain the phosphor with...

Embodiment 3

[0085] Take polyvinyl alcohol (PVA), diazo resin, fluorescent powder, nano-titanium dioxide powder and deionized water and mix evenly to form a stable PVA photosensitive adhesive dispersion containing fluorescent powder particles.

[0086] Use the dipping method (Flowing) to coat the phosphor powder photosensitive adhesive dispersion on the surface of the LED chip (wafer wafer) to control the required thickness.

[0087] Dry it with hot air, expose it with an ultraviolet light source combined with a mask plate, develop it with hot water, and get a phosphor powder photosensitive adhesive dispersion coating pattern on the surface of the LED chip (Wafer) in the light emitting direction.

[0088] Put the LED chip (Wafer) coated with phosphor photosensitive adhesive into a baking oven, bake at 300~500°C for a period of time, heat and oxidize, remove the organic components in the photosensitive adhesive, and obtain the determination of the phosphor powder layer pattern.

[0089] Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com