Lithium-oxygen battery capable of improving battery energy density and method for manufacturing lithium-oxygen battery

A lithium-oxygen battery and battery energy technology, applied in the direction of fuel cell half-cells and secondary battery-type half-cells, active material electrodes, etc., can solve space utilization, material utilization, weight saving and safety technical indicators Poor, difficult to meet the capacity requirements of electric vehicles, low utilization of battery electrodes, etc., to achieve the effect of increasing the working voltage and open circuit voltage, improving space utilization, and increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

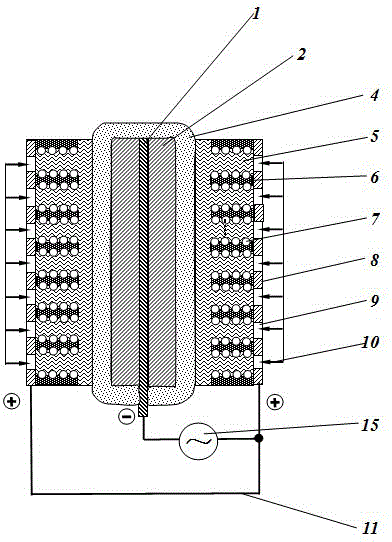

[0064] (1) Preparation of the positive electrode element: nickel foam is used as the positive electrode current collector 8, and the holes of the nickel foam are used as compressed air channel holes 9 for compressed air to enter, and a load of 20wt% Mn 2.7 Ni 0.3 o 4 Sheet-like nanostructured graphene as the oxygen reduction catalyst 7 is used as the carbon-oxygen positive electrode material 6, the conductive agent is acetylene black, and the binder is polytetrafluoroethylene (PTFE). The detailed formula is acetylene black: binder: nanostructured graphene = 5:12:88. According to this ratio, a slurry is made, and the surface of nickel foam is coated, then rolled, baked and dried to make a positive electrode component. An electrode post is welded to one end of the positive electrode collector 7 .

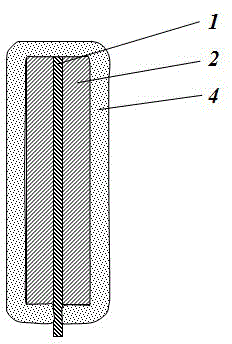

[0065] (2) Preparation of the negative electrode element: the negative electrode current collector 1 is made of nickel foil with a thickness of 0.1 mm. The negative electrode mater...

Embodiment 2

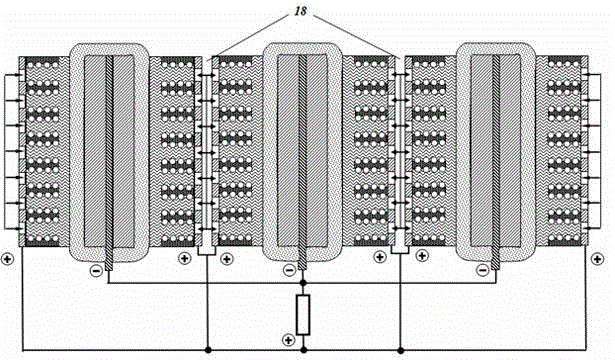

[0074] like Figure 2~6 The lithium-oxygen battery shown is an embodiment of the present invention, and the difference from embodiment 1 is:

[0075] (2) Negative electrode element: the negative electrode current collector 1 is made of copper foil with a thickness of 0.1 mm.

[0076] (3) Solid electrolyte diaphragm: solid electrolyte diaphragm 4 adopts polyethylene oxide PEO with catalyst 18 LiTFSI film. The polymer film is made into a packaging bag for wrapping the negative electrode element in advance, and the part with the lithium metal sheet in the negative electrode element is inserted into the packaging bag, and then the solid electrolyte diaphragm is pressed on the surface of the two lithium metal sheets and The opening of the packaging bag was sealed, thereby sealing the periphery of the part having the lithium metal sheet in the negative electrode element. The polymer film has a thickness of 100 μm and a Li-ion conductivity of 10 -4 S / cm, electrochemical window>5V...

Embodiment 3

[0079] The difference between this embodiment and embodiment 1 is:

[0080] (1) Preparation of positive electrode components: Nickel mesh is used as the positive electrode current collector 8, and columnar nanostructured graphene is used as the carbon-oxygen positive electrode material 6.

[0081] (2) Negative electrode element: the negative electrode current collector 1 adopts a nickel mesh with a thickness of 0.1mm.

[0082] A pure lithium sheet with a thickness of 0.5 mm was used as the negative electrode material.

[0083] (3) Solid electrolyte diaphragm: solid electrolyte diaphragm 4 adopts polyethylene oxide PEO with catalyst 18 LiTFSI film. The polymer film is made into a packaging bag for wrapping the negative electrode element in advance, and the part with the lithium metal sheet in the negative electrode element is inserted into the packaging bag, and then the solid electrolyte diaphragm is pressed on the surface of the two lithium metal sheets and The opening of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com