Fractional distillation equipment for separating propargyl alcohol and method of equipment

A technology of propynyl alcohol and rectification tower, which is applied in the field of fractionation equipment for separating propynyl alcohol, can solve the problems of high energy consumption, achieve the effects of simplifying the separation process, improving product quality, and improving the separation capacity of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] With reference to the accompanying drawings, the following embodiments will help to understand the present invention, but these embodiments are only for illustrating the present invention, and the present invention is not limited to these contents.

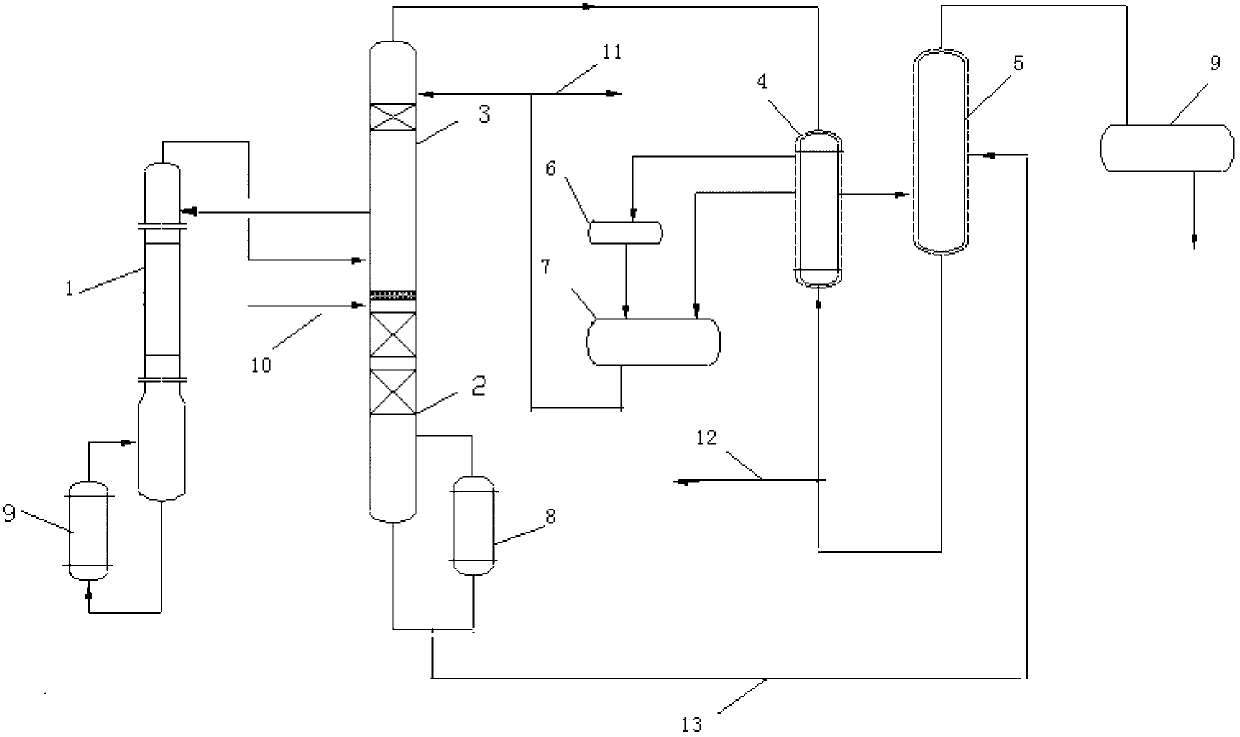

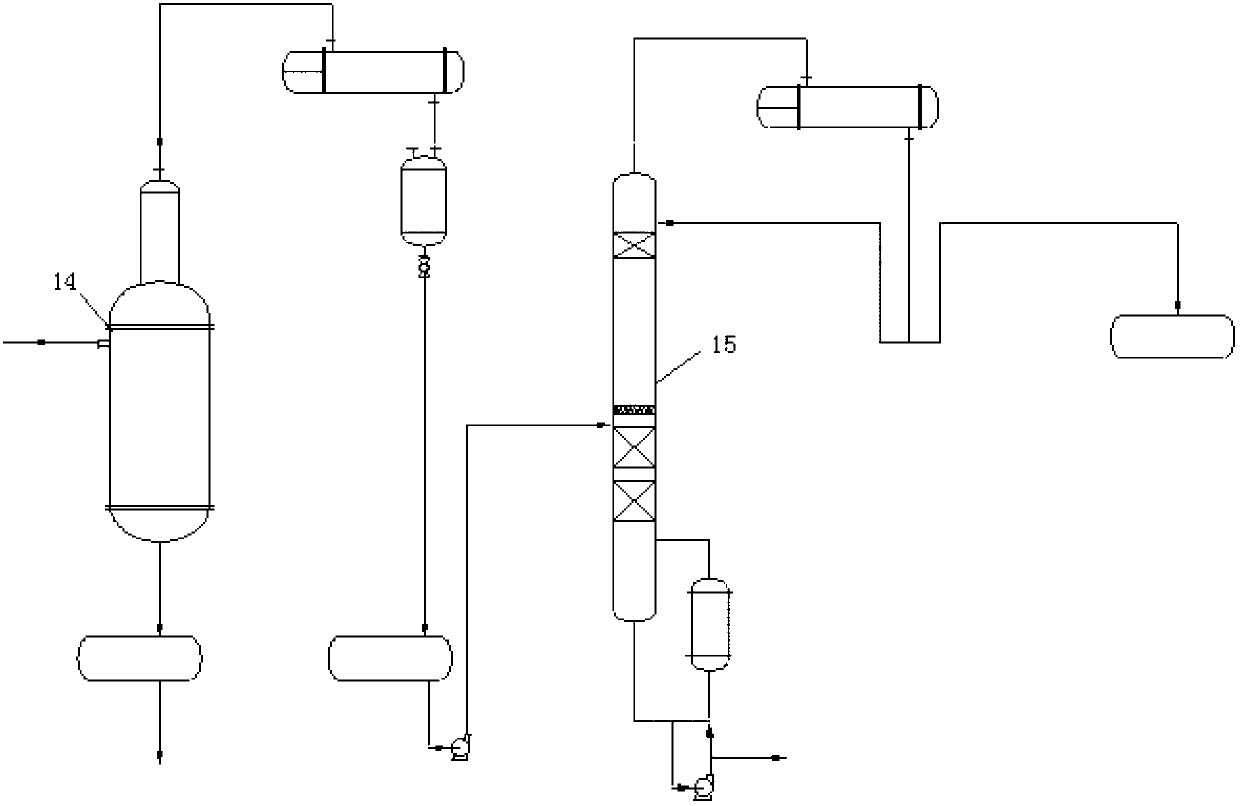

[0011] A fractionation equipment for separating propynyl alcohol, comprising a double wall tower 1, a rectification tower stripping section 2, a rectification tower rectification section 3, a rectification tower condenser 4, a vacuum evaporator 5, and a rectification tower tail cooler 6 , a reflux tank 7, a heater 8, a vacuum evaporator cooler 9, a mixture feed port 10, a first pipeline 11, a second pipeline 12, and a third pipeline 13. The sandwiched wall tower 1 is composed of a stripping section. The top of the wall tower 1 is provided with a lye feed inlet; the rectification tower is composed of a rectification tower stripping section 2 and a rectification tower rectification section 3, between the rectification tower st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com