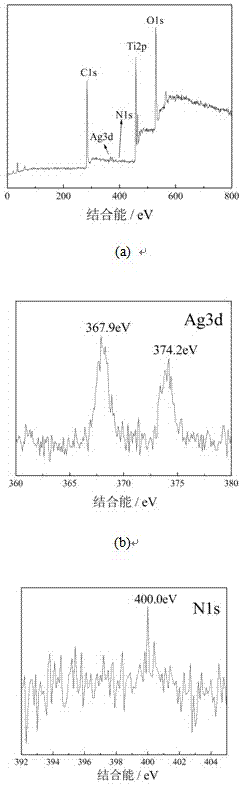

Rodlike N-Ag codoped TiO2 and preparation method thereof

A co-doped, rod-shaped technology, applied in the direction of titanium oxide/hydroxide, nanotechnology, titanium dioxide, etc., can solve the problems of great harm to the human body, and achieve the effects of reducing pollution, excellent performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh 0.007g of urea (the molar ratio of N and Ti is 1:100), 8 mL of butyl titanate and 32 mL of absolute ethanol, pour them into the same three-necked flask, turn on the magnetic stirring, and mix them evenly. dubbed into a solution;

[0026] (2) After 5 min, turn on the air pump switch, with 40 L min -1 The air is delivered to the water in the airtight container at a rate of 2.5-3.5g·L through another port on the container. -1 , input the gas containing water into the mixed solution of butyl titanate and ethanol. Under the condition of mechanical stirring, the mixed solution gradually becomes turbid from light yellow transparent liquid, and finally turns into white emulsion. Stop inputting air and react for 30 minutes. stop;

[0027] (3) Distill the three-neck flask containing the white emulsion under reduced pressure to collect absolute ethanol for reuse; collect the white powder, put it in a blast drying oven, and let it stand at 40 °C for 12 h to obtain a d...

Embodiment 2

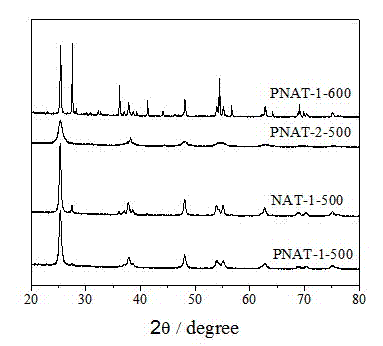

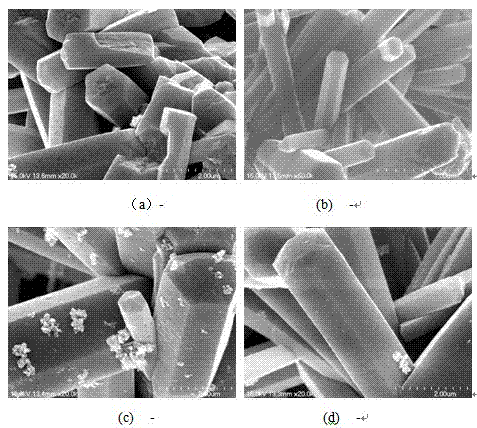

[0031] According to the technical scheme of Example 1, the nanopowder obtained in step (4) was calcined at 500 °C for 2 h to obtain rod-shaped N and Ag co-doped TiO calcined at 500 °C without nitrogen protection. 2 , marked as NAT-1-500, its X-ray diffraction pattern is shown in the attached figure 1 The curve b of the scanning electron microscope is shown in the appendix figure 2 Figure (b).

Embodiment 3

[0033](1) Weigh 0.007 g of urea and 0.009 g of ammonium nitrate (the molar ratio of N and Ti is 2:100) and dissolve them in 8 mL of butyl titanate and 32 mL of absolute ethanol; pour them into the same three-necked flask, and turn on the magnetic stirring , make it evenly mixed to form a solution;

[0034] (2) After 5 min, turn on the air pump switch, with 40 L min -1 The air is delivered to the water in a closed container with a small amount of water at a certain rate, and the air containing water is output through another port on the container, and the quality of the water vapor delivered is 2.5~3.5g·L -1 , input the gas containing water into the mixed solution of butyl titanate and ethanol, and carry out mechanical stirring. The mixed solution gradually becomes turbid from a light yellow transparent liquid, and finally turns into a white emulsion. Stop inputting air, and stop after 30 minutes of reaction;

[0035] (3) Distill the three-neck flask containing the white emul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com