Method for extracting vanadium from burning slag of stone coal vanadium mine fluidized bed

A technology of burning ash and stone coal vanadium, which is applied in the field of vanadium extraction, can solve the problems of low recovery rate, unstable operation, low roasting conversion rate, etc., and achieve the effects of reducing the consumption of sulfuric acid, reducing the burden of desiliconization, and lowering the roasting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

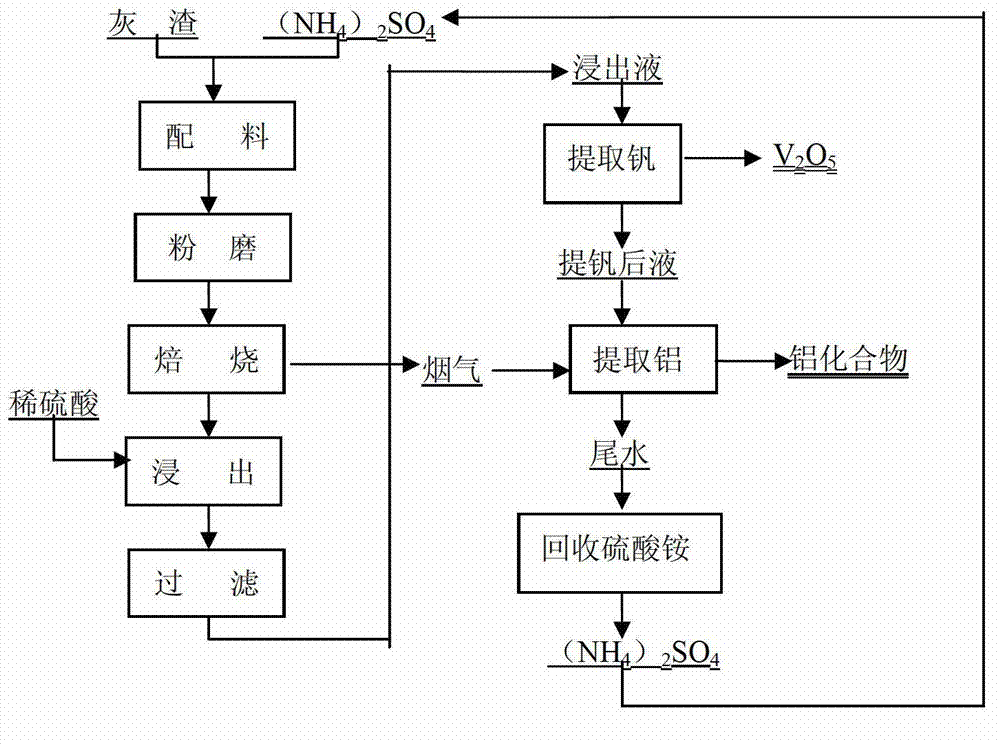

Image

Examples

Embodiment 1

[0037] Hunan Xiangzhong Mining Company's fluidized bed combustion ash contains V 2 O 5 1.25% Al 2 O 3 8.23%, grind the ash and ammonium sulfate at a mass ratio of 1:1.1 to 69% with a particle size of less than 0.043mm, then roast at 380°C for 2h, and use 2 times the weight of the roasted material at 80°C to 3% H 2 SO 4 The solution was leached for 3 hours, the leaching rate of vanadium was 90.1%, and the leaching rate of aluminum reached 93.1%.

Embodiment 2

[0039] The fluidized bed combustion ash and ammonium sulfate of Example 1 were mixed and ground at a mass ratio of 1:0.9 to 90% with a particle size of less than 0.043mm, then calcined at 500°C for 1h, and at 90°C with 2 times the weight of the calcined material 10%H 2 SO 4 The solution was leached for 0.5h, the leaching rate of vanadium was 88.9%, and the leaching rate of aluminum reached 91.8%.

Embodiment 3

[0041] The fluidized bed combustion ash of a vanadium industry company in Guangxi contains Al 2 O 3 18.2%V 2 O 5 1.43%. After mixing furnace ash and ammonium sulfate at a mass ratio of 1:1.5 to 60% with a particle size of less than 0.043mm, smelt at 400℃ for 3h, and at 70℃, leaching with 5% sulfuric acid solution 1.8 times the weight of the calcined material 0.5h, the leaching rate of vanadium reached 88.7%, and the leaching rate of aluminum reached 90.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com