Method for producing monocrystalline silicon cast ingot

A production method, single crystal silicon technology, applied in the direction of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of battery efficiency reduction, achieve the effects of reducing light attenuation, low energy consumption, and improving photogenerated current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

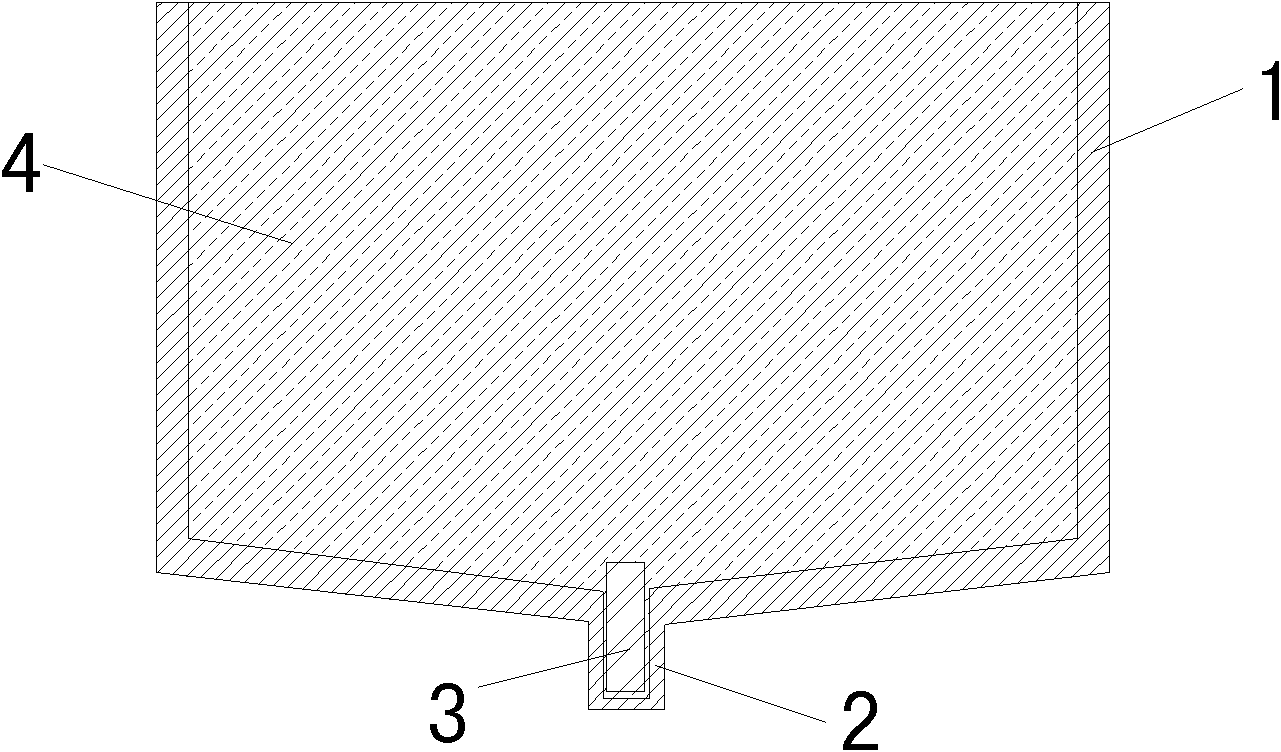

[0029] 1) Put the dislocation-free raw material monocrystalline silicon block as the seed crystal 3 into the seed crystal tank 2 of the crucible 1. The crucible is a square quartz ceramic crucible coated with silicon nitride. The main body of the crucible is 450Kg grade 840mm*840mm*400mm , make sure that the crystal direction of the seed crystal is vertically upward; then place 450Kg polysilicon 4 on the raw material monocrystalline silicon block 3, and add P-type dopant boron to keep the doped crystal resistivity at 1.5- 2Ω·cm.

[0030] 2) The furnace chamber of the ingot casting furnace is evacuated and then directly fed with argon gas. Adjust the position of the crucible so that the dopant, polysilicon and part of the seed crystal close to the polysilicon are heated; gradually heating to above 1412°C makes the polysilicon begin to melt, and keeps the temperature above 1412°C for a period of time, so that the dopant, polysilicon and the seed crystal close to the polysilicon...

Embodiment 2

[0034] 1) Put the dislocation-free raw material monocrystalline silicon block as the seed crystal 3 into the seed crystal tank 2 of the crucible 1. The crucible is a silicon nitride-coated round quartz ceramic crucible, and the main body of the crucible is a 60Kg-grade 18-inch crucible. The height is 450mm, and the crystal direction of the seed crystal is determined to be vertically upward; then 50Kg of polysilicon 4 is placed on top of 3 pieces of raw material single crystal silicon, and the P-type dopant boron is added to keep the resistivity of the doped crystal At 1.5-2Ω·cm.

[0035] 2) The furnace chamber of the ingot casting furnace is evacuated and then directly fed with argon gas. Adjust the position of the crucible in the furnace so that the dopant, polysilicon and some seed crystals close to the polysilicon are heated; gradually heating to above 1412°C makes the polysilicon begin to melt, and keeps the temperature above 1412°C for a period of time, so that the dopan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com