Anti-bacterial and anti-wrinkling finishing method for cotton fabric

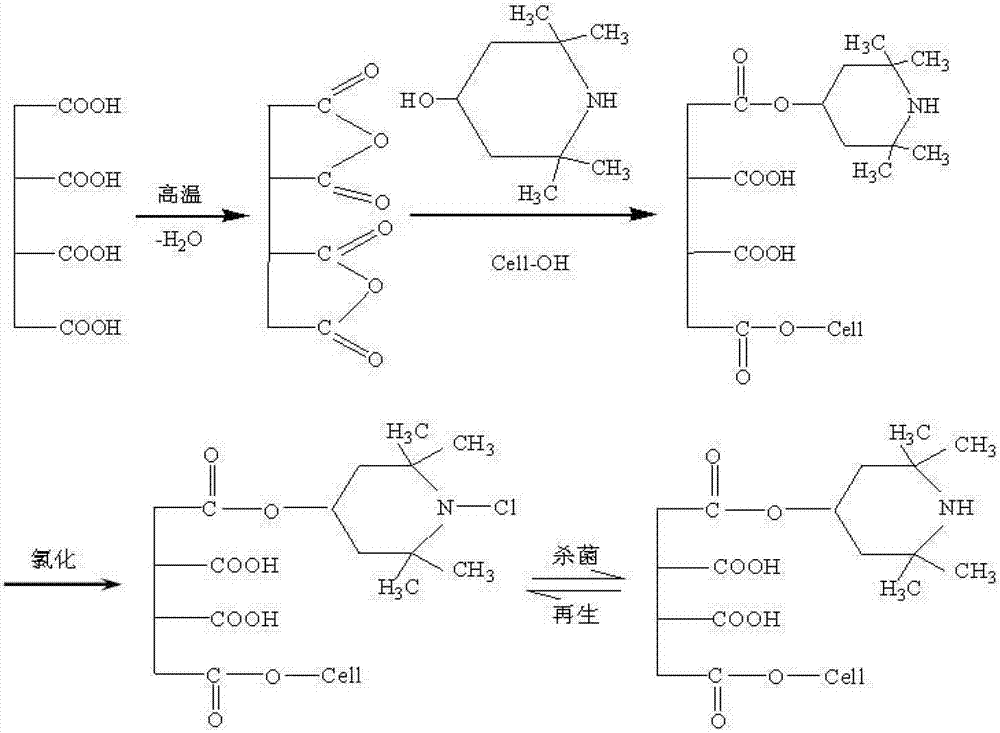

An anti-wrinkle finishing, cotton fabric technology, applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve the problems of fabric strength loss, irritation of human skin and respiratory mucosa, carcinogenicity, etc., to achieve wrinkle recovery angle improvement, antibacterial efficiency High, formaldehyde-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

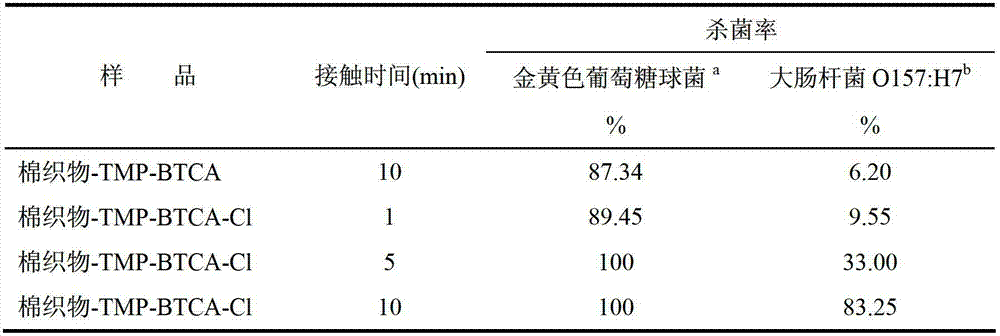

Examples

Embodiment 1

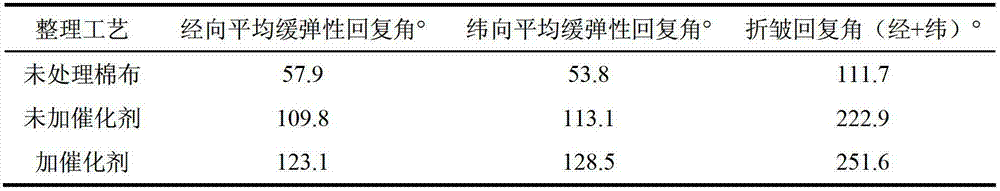

[0018] Dissolve sodium dihydrogen phosphate, equimolar 2,2,6,6-tetramethyl-4-piperidinol (TMP) and butane tetracarboxylic acid (BTCA) in water to form a finishing bath, in which phosphoric acid di The mass percent concentration of sodium hydrogen was 10%, and the mass percent concentration of 2,2,6,6-tetramethyl-4-piperidinol (TMP) was 1%; the untreated cotton fabric samples (purchased (Zhejiang Guandong Printing and Dyeing Garment Co., Ltd.) was immersed in the finishing bath liquid, and it was pressed and rolled on the padding car by means of two dipping and two rolling. The time was 10 minutes, and the rolling rate was 100%. ℃ pre-baking in a dryer for 10 minutes, and then baking in a baking machine at 150 ℃ for 300s; soaping the cotton fabrics after the above-mentioned baking treatment (washing the finished cotton fabrics in commercially available washing liquid for 15 minutes ), then wash and dry, and finally soak the dried cotton fabric in a sodium hypochlorite solution ...

Embodiment 2

[0020] Dissolve disodium hydrogen phosphate, equimolar 2,2,6,6-tetramethyl-4-piperidinol (TMP) and butane tetracarboxylic acid (BTCA) in water to form a finishing bath, in which hydrogen phosphate The mass percentage concentration of disodium is 5%, and the mass percentage concentration of 2,2,6,6-tetramethyl-4-piperidinol (TMP) is 5%; the untreated cotton fabric sample (same as above ) dipped in the finishing bath liquid, and rolled it on the padding car by means of double dipping and rolling for 10 minutes, and the liquid rolling rate was 100%. The cotton fabric was taken out and pre-dried in a dryer at 90°C 6min, then bake in a baking machine at 180°C for 210s; soap the cotton fabric after the above baking treatment (wash the finished cotton fabric in commercially available washing liquid for 15min), then wash and dry, Finally, soak the dried cotton fabric in a 0.5% sodium hypochlorite solution (pH 7.0) by mass percentage, take out the cotton fabric after 1 hour, and dry it...

Embodiment 3

[0022] Sodium polyphosphate, equimolar 2,2,6,6-tetramethyl-4-piperidinol (TMP) and butane tetracarboxylic acid (BTCA) are dissolved in water to form a finishing bath, in which poly The mass percentage concentration of sodium phosphate is 5%, and the mass percentage concentration of 2,2,6,6-tetramethyl-4-piperidinol (TMP) is 5%; the untreated cotton fabric sample (same as above ) dipped in the finishing bath liquid, and rolled it on the padding car by means of double dipping and rolling for 10 minutes, and the liquid rolling rate was 100%. The cotton fabric was taken out and pre-dried in a dryer at 100°C 5min, then bake in a baking machine at 180°C for 120s; soap the cotton fabric after the above baking treatment (wash the finished cotton fabric in commercially available washing liquid for 15min), then wash and dry, Finally, soak the dried cotton fabric in a calcium hypochlorite solution (pH 7) with a concentration of 0.5% by mass, take out the cotton fabric after 1 hour, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com