Method for preparing photoluminescence carbon quantum dot

A carbon quantum dot and photoluminescence technology, applied in the fields of chemistry and nanomaterials science, can solve the problems of difficult large-scale production and promotion, cumbersome process steps, human health pollution, etc., and achieves easy promotion, simple preparation process equipment, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

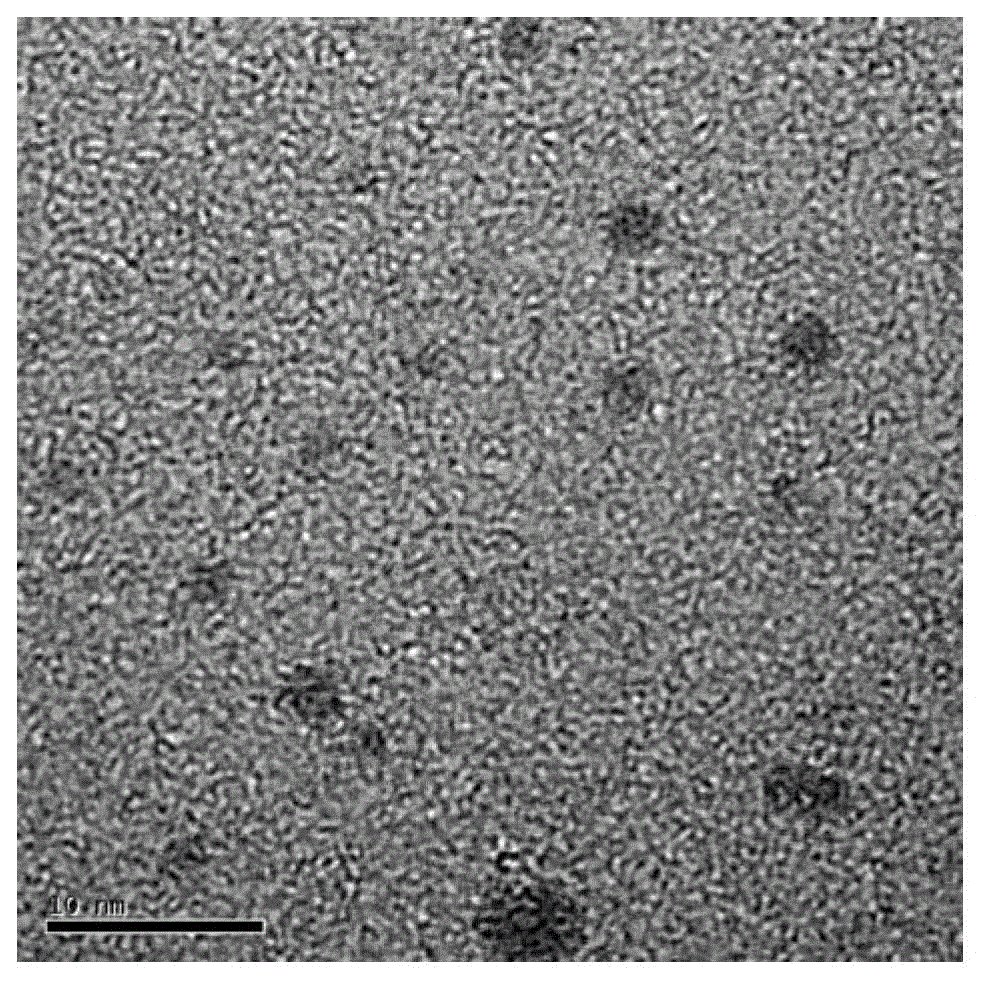

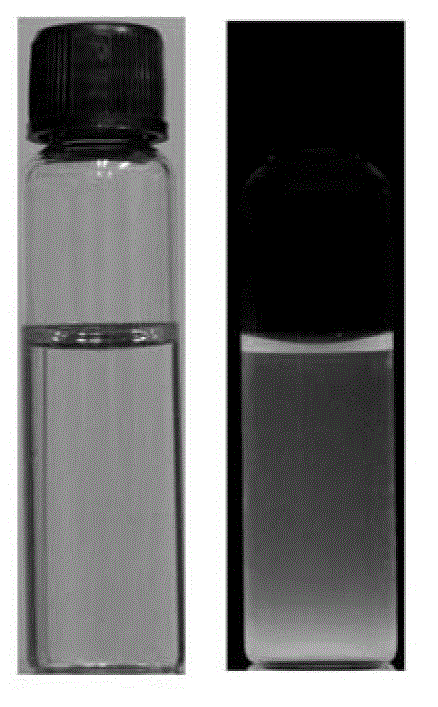

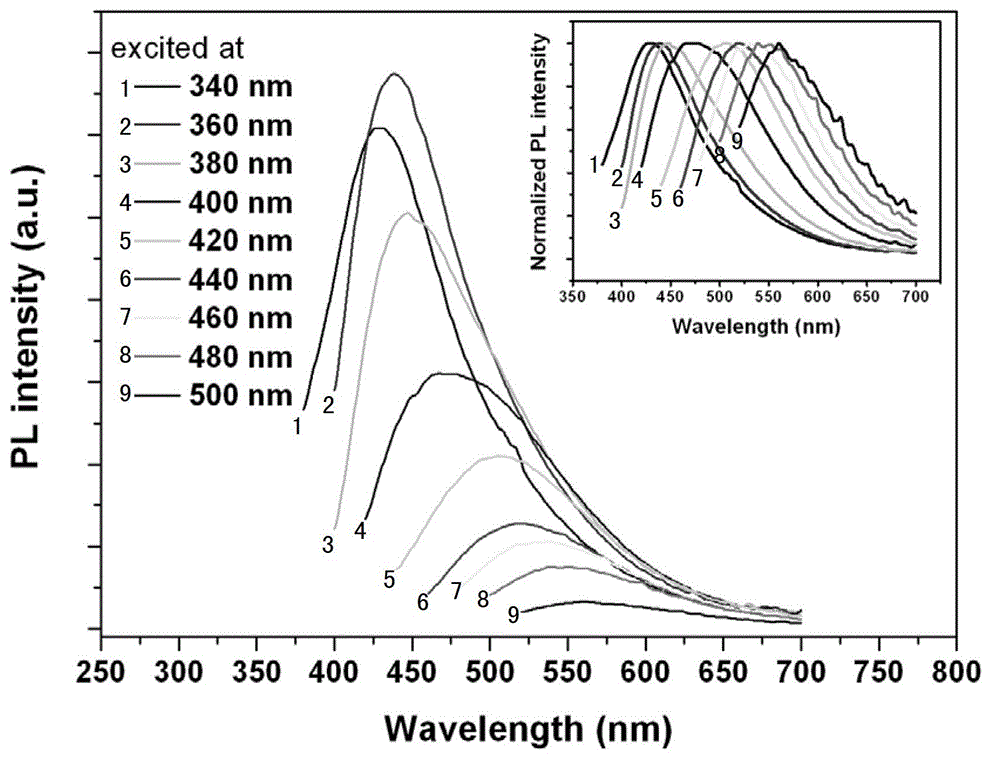

[0023] The solid residue left after extracting soybean milk from soybeans is dried in an oven at 80°C to remove moisture, and then ground to a uniform bean dregs powder, which is evenly dispersed in a glass petri dish; the glass petri dish is placed in an electric heating drum with a power of 850W Heat the center of the tray in the air drying oven at a heating temperature of 200°C and a heating time of 20 minutes to obtain the crude product of carbon quantum dots; grind the crude product of carbon quantum dots and pass through a 200-mesh (200 mesh / square inch) sieve, Obtain a finer carbon quantum dot crude product powder; disperse the above carbon quantum dot crude product powder in a beaker filled with deionized water, stir vigorously with a glass rod, and let stand at room temperature (15-25°C) for 60 minutes. Then centrifuge at 4000rpm for 10min, retain the supernatant and place it in a rotary evaporator for evaporation to remove most of the water to obtain a concentrated so...

Embodiment 2

[0025] The solid residue left after extracting soybean milk from soybeans is dried in an oven at 80°C to remove moisture, and then ground to a uniform bean dregs powder, which is evenly dispersed in a glass petri dish; the glass petri dish is placed in an electric heating drum with a power of 850W Heat the center of the tray in the air drying oven at a heating temperature of 200°C and a heating time of 30 minutes to obtain the crude product of carbon quantum dots; grind the crude product of carbon quantum dots and sieve through a 200-mesh sieve to obtain finer carbon quantum dot crude products. Product powder: Disperse the above-mentioned carbon quantum dot crude product powder in a beaker filled with deionized water, stir vigorously with a glass rod, let stand at room temperature for 60min, then centrifuge at 4000rpm for 10min, keep the supernatant and place it in a spinner Evaporate in an evaporator to remove most of the water to obtain a concentrated solution, which is then ...

Embodiment 3

[0027] The solid residue left after extracting soybean milk from soybeans is dried in an oven at 80°C to remove moisture, and then ground to a uniform bean dregs powder, which is evenly dispersed in a glass petri dish; the glass petri dish is placed in an electric heating drum with a power of 850W Heat the center of the tray in the air drying oven at a heating temperature of 200°C and a heating time of 40 minutes to obtain the crude product of carbon quantum dots; grind the crude product of carbon quantum dots and sieve through a 200-mesh sieve to obtain finer carbon quantum dot crude products. Product powder: Disperse the above-mentioned carbon quantum dot crude product powder in a beaker filled with deionized water, stir vigorously with a glass rod, let stand at room temperature for 60min, then centrifuge at 4000rpm for 10min, keep the supernatant and place it in a spinner Evaporate in an evaporator to remove most of the water to obtain a concentrated solution, which is then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com