Method for preparing graphene and polyoxometalate composite through electrochemical reduction

A technology of multi-metal oxygen clusters and composite materials, applied in chemical instruments and methods, graphene, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

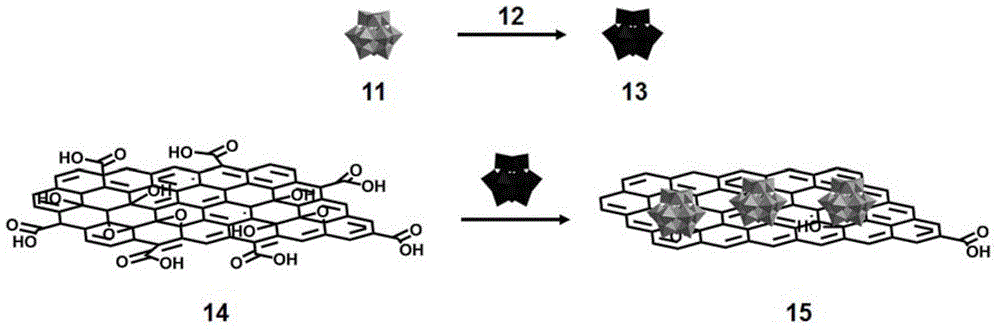

Method used

Image

Examples

Embodiment 1

[0046] Weigh 2g NaNO 3 And 2g graphite in a 1L beaker, add 96mL concentrated sulfuric acid (mass fraction 98%) under stirring in an ice water bath (300rpm), and stir for 10min; slowly add 12g KMnO with a small medicine spoon 4 Add to it and stir for 1.5h in an ice-water bath; then heat to 35℃ and stir for 2h; slowly add 80mL of water with a dropper for about 30min, then directly pour 200mL of water (600rpm), and then add 10mL of H 2 O 2 (Mass fraction 30%), stir for 10min; finally add about 10mL of H 2 O 2 , Until all the manganese compounds in the solution are converted into colorless compounds; centrifuge at 12000rpm for 15min, dialyze to pH 5-6; dilute with water to 1000mL, sonicate for 10min, and centrifuge at 5000rpm for 10min to remove unstripped carbon particles; Centrifuge at 12000 rpm for 1 hour to collect the flocculent viscous material. The collection still contains a lot of water. Add about 200 mL of ethanol, centrifuge, collect the precipitate, and dry it in a vacuum ...

Embodiment 2

[0048] Example 2: Preparation of a mixture of graphene oxide and 12-tungstosilicic acid

[0049] Weigh 100 mg of the graphene oxide prepared in Example 1 and place it in a 250 mL two-neck round bottom flask, add 90 mL of water, and stir with ultrasonic (100W) (300 rpm) for 1 h. The graphene oxide is completely dispersed to obtain an aqueous graphene oxide suspension; Dissolve 2.88 g of 12-tungstosilicic acid in 10 mL of water, add dropwise to the graphene oxide aqueous suspension under the combined action of ultrasound and stirring; after the dropwise addition, continue to ultrasonically stir for 1 hour; add ice to cool the entire process. In the mixed solution, the concentration of graphene oxide is 1 mg / mL and the concentration of 12-tungstosilicic acid is 10 mM.

Embodiment 3

[0050] Example 3: Preparation of a mixture of graphene oxide and 12-tungstosilicic acid

[0051] Weigh 100 mg of the graphene oxide prepared in Example 1 and place it in a 250 mL two-neck round bottom flask, add 90 mL of water, and stir with ultrasonic (100W) (300 rpm) for 1 h. The graphene oxide is completely dispersed to obtain an aqueous graphene oxide suspension; Dissolve 5.76 g of 12-tungstosilicic acid in 10 mL of water, add dropwise to the graphene oxide aqueous suspension under the combined action of ultrasound and stirring; after the addition, continue to stir with ultrasound for 1 hour; add ice to cool the entire process. In the mixed solution, the concentration of graphene oxide is 1 mg / mL, and the concentration of 12-tungstosilicic acid is 20 mM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com