Novel crystal form of cefuroxime acid and preparation method thereof

A technology of cefuroxime acid and crystal form, which is applied in the field of new crystal form of cefuroxime acid and its crystal preparation, can solve the problems of poor crystal form of cefuroxime acid, high labor intensity, difficulty in filtration and drying, etc., and achieves thermal stability Good, low labor intensity, complete crystal form effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 5g of cefuroxime sodium to a container containing 50ml of acetonitrile and N,N-dimethylformamide mixed solvent (volume ratio 1:9), stir and dissolve at a constant temperature of 25°C, and after continuous stirring for 30 minutes, Filter and decolorize. Transfer the filtrate into a crystallizer, add 6mol / l hydrochloric acid solution to adjust the pH of the solution to 3, cool to 15℃, add 0.25g seed crystals, grow crystals for 1h, add 50ml eluent water, continue to cool to 5℃, grow crystals for 1h After suction filtration, the filter cake was washed with 10 ml of pure water, and dried at 30° C. under a vacuum of 0.08 MPa for 5 hours. The molar yield of the final crystal product was 88.3%. The HPLC purity is 99.3%, and the main particle size is 120 μm.

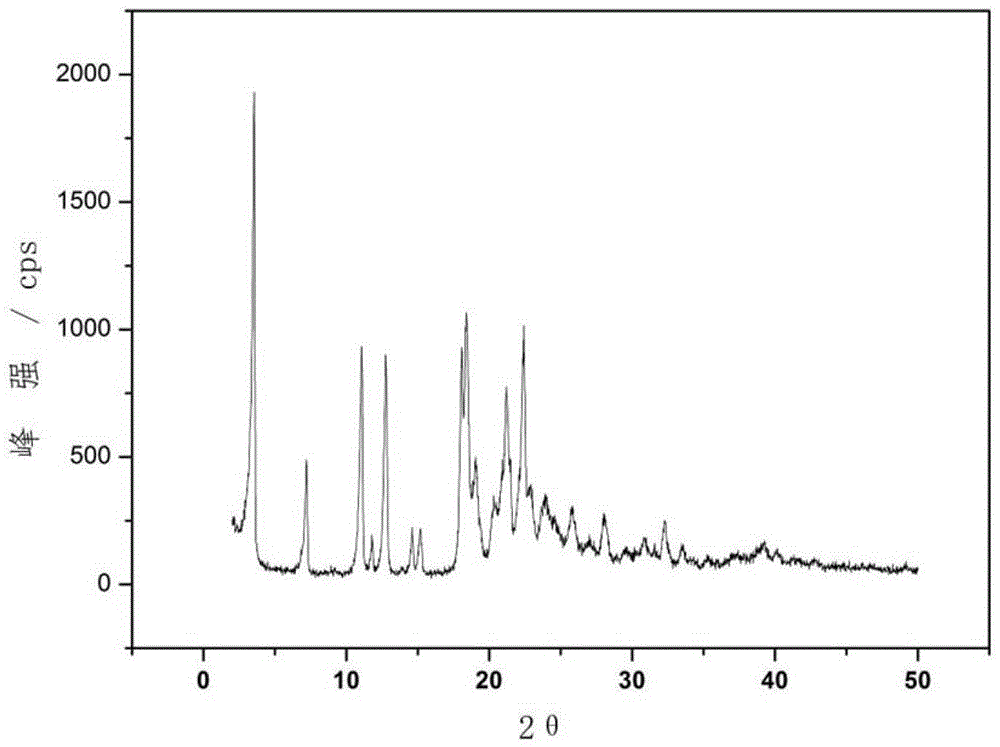

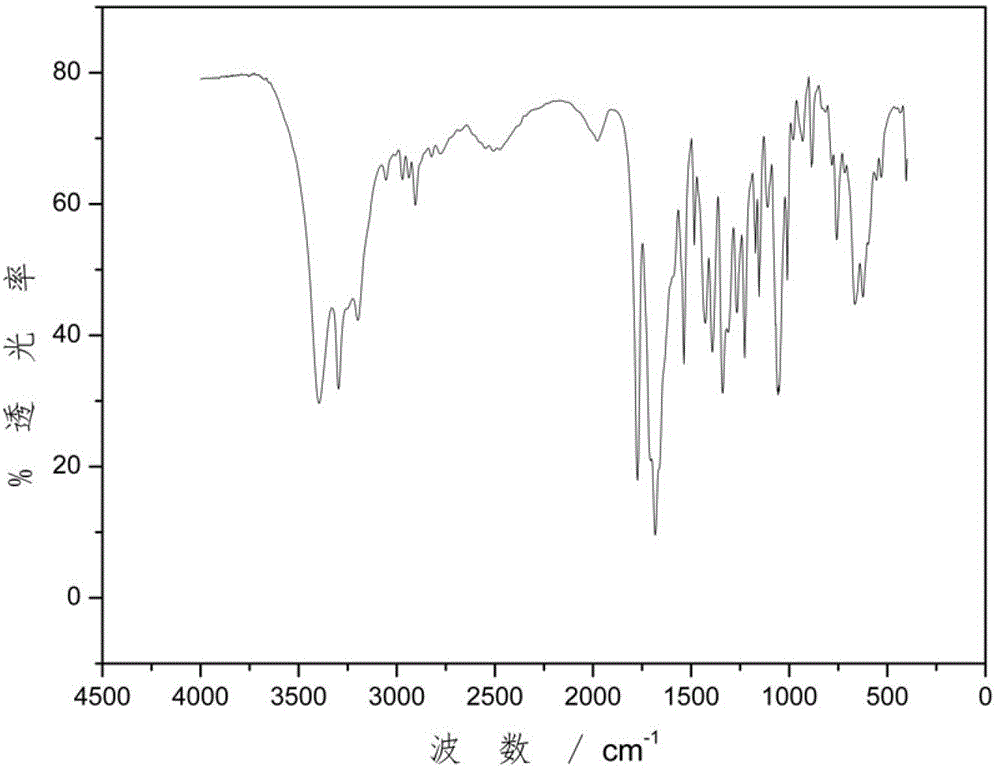

[0027] The XRD pattern of the resulting product is as figure 2 As shown, the infrared absorption spectrum is as image 3 As shown, the scanning electron microscope photos are as Figure 4 Shown.

Embodiment 2

[0029] Add 5g of cefuroxime acid to a container containing 30ml of a mixed solvent of acetonitrile and acetone (volume ratio 1:5), stir to dissolve at a constant temperature of 30°C, continue stirring for 40 minutes, filter and decolorize. Transfer the filtrate into a crystallizer, add 3mol / l hydrochloric acid solution to adjust the pH of the solution to 3.5, cool to 15°C, add 0.15g seed crystals, grow the crystals for 2h, add 100ml of eluent ethyl acetate, and continue to cool to 2°C. After crystallizing for 3 hours, filter with suction, wash the filter cake with 10ml ethyl acetate, and dry for 12 hours at 40°C under a vacuum of 0.05MPa. The molar yield of the final crystal product was 90.2%. The HPLC purity is 99.5%, and the main particle size is 130 μm.

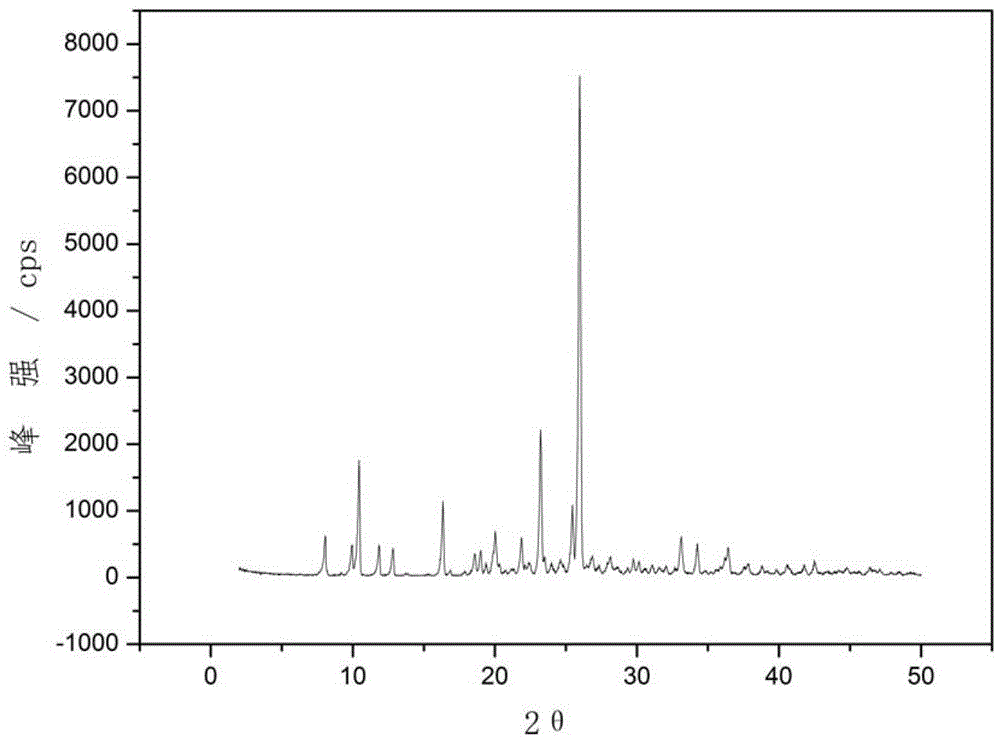

[0030] The XRD of the product has characteristic peaks at 8.06, 9.96, 10.45, 11.84, 12.82, 16.33, 19.02, 20.03, 21.86, 23.22, 25.46, 25.99, 33.12, 34.22 and 36.40 degrees. The infrared absorption spectrum is at 3396.03, 3296...

Embodiment 3

[0032] Add 25g of cefuroxime sodium to a container containing 125ml of mixed solvent of acetonitrile and N,N-dimethylformamide (volume ratio 1:4), stir and dissolve at a constant temperature of 35°C, and after continuous stirring for 60 minutes, Filter and decolorize. Transfer the filtrate into a crystallizer, add 6mol / l hydrochloric acid solution to adjust the pH of the solution to 3.8, cool to 10°C, add 0.025g seed crystals, grow crystals for 1.3h, add 550ml eluent water, continue to cool to 0°C, grow crystals After 2.5h, filter with suction, wash the filter cake with 40ml pure water, and dry for 7h at a vacuum of 0.09MPa at 50°C. The molar yield of the final crystal product was 91.5%. The HPLC purity is 99.4%, and the main particle size is 110 μm.

[0033] The XRD of the product has characteristic peaks at 8.07, 9.96, 10.44, 11.85, 12.82, 16.34, 19.03, 20.02, 21.86, 23.21, 25.46, 25.98, 33.14, 34.24 and 36.40 degrees. The infrared absorption spectrum is at 3396.01, 3296.56, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com