Method for culturing chlorella by heterotrophism with sludge hydrolysate

A technology of chlorella and hydrolyzate, applied in the direction of microorganism-based methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of high cost of microalgae biodiesel, achieve resource utilization and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

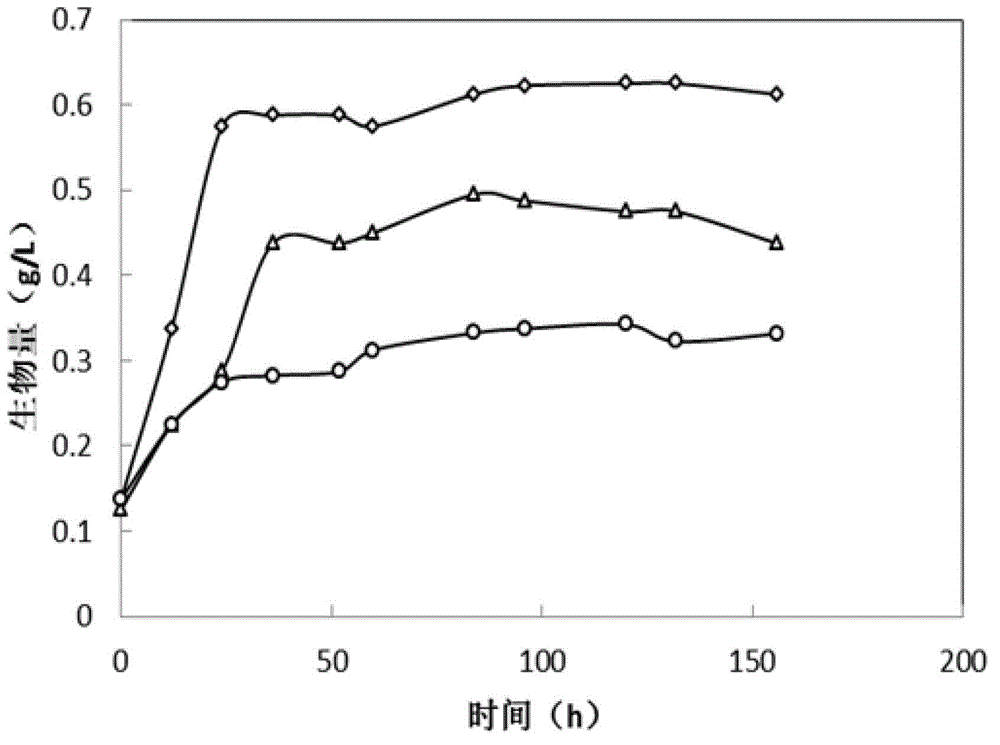

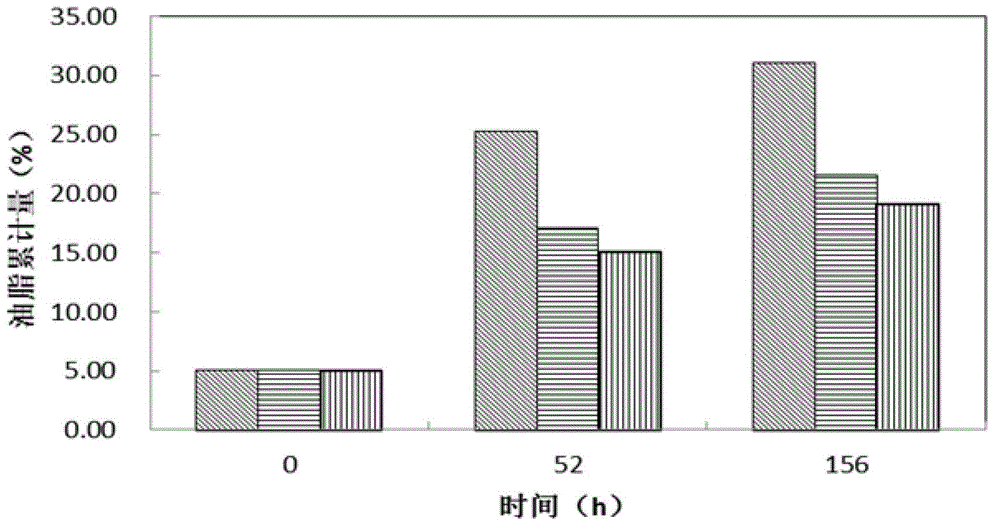

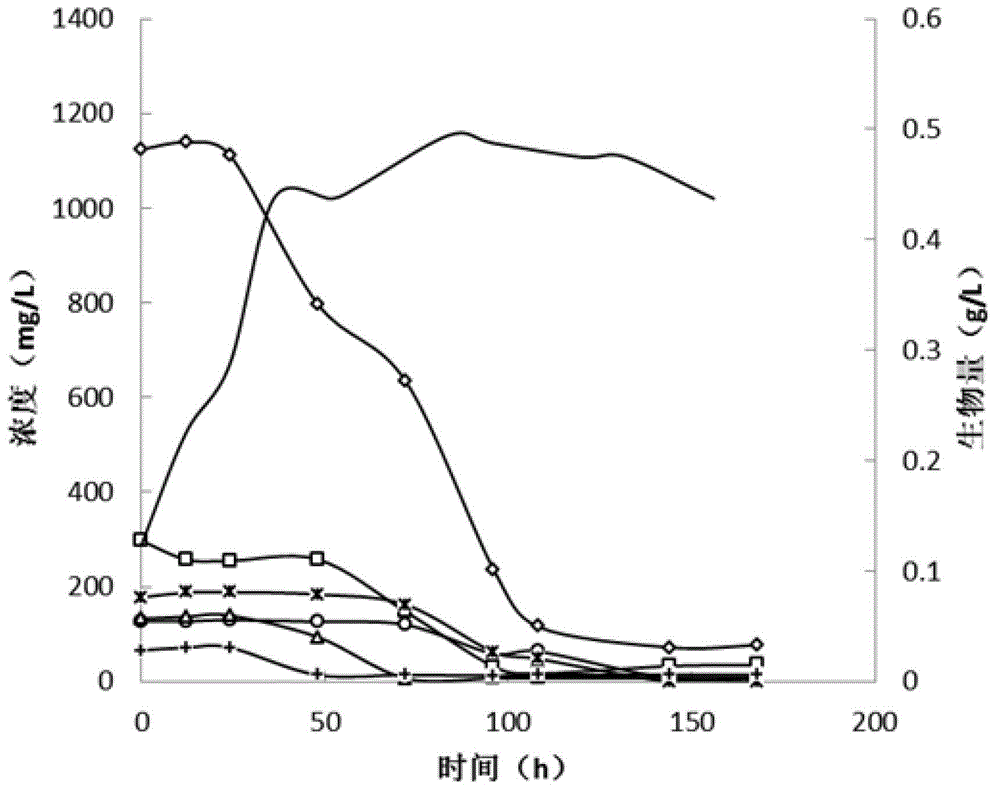

[0015] Specific embodiment 1: A method for heterotrophic cultivation of chlorella using sludge hydrolysate in this embodiment is carried out according to the following steps: 1. Ultrasonic treatment of sludge: take the remaining sludge from the domestic sewage treatment plant and remove the The moisture content of the sludge is concentrated to a mass percentage of 98%~98.5%, and ultrasonic treatment is carried out for 8~10min under the conditions of a sound energy density of 5~10W / mL and a pulse ratio of 2:1; 2. Sludge hydrolysate Preparation of sludge: Anaerobic hydrolysis of the sludge after ultrasonic treatment in step 1 at a speed of 180r / min and a temperature of 35°C is carried out for 2~3d. During the hydrolysis process, the pH value is adjusted to 9.0 every 12h, and At a nitrogen flow rate of 0.3m 3 Under the condition of / h, the nitrogen is blown off every 12h to obtain the sludge hydrolysate; 3. Add trace elements and other nutrients to the sludge hydrolysate obtained i...

specific Embodiment approach 2

[0018] Specific embodiment two: this embodiment is different from specific embodiment one in that the pH value adjustment described in step two is carried out with 1 mol / L NaOH. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: This embodiment is different from specific embodiments one to two in that the high-pressure steam sterilization operating conditions described in step three are: 121° C., 121 KPa, and sterilization for 30 minutes. Others are the same as the first to second specific embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com