Water quenching method for producing cold rolling phase transition reinforced high strength strip steel

A phase transformation strengthening and high-strength technology, used in quenching devices, heat treatment equipment, furnaces, etc., can solve the problems of uneven cooling speed of water quenching, uneven cooling of strip steel, and poor shape of water quenched strip steel, and achieve uniform water quenching. The effect of quenching cooling speed, reducing liquid level fluctuation and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

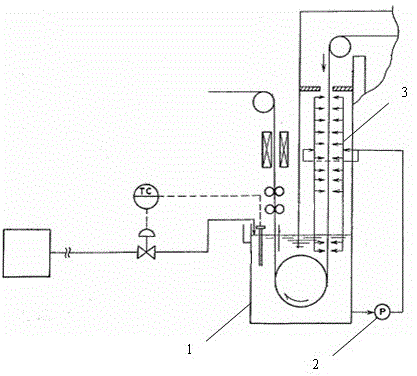

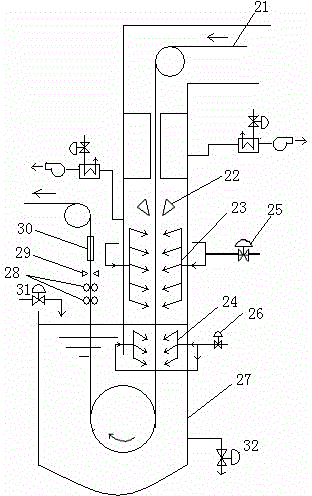

[0040] Hereinafter, the water quenching method of the present invention will be further described in detail with reference to the drawings and embodiments of the specification.

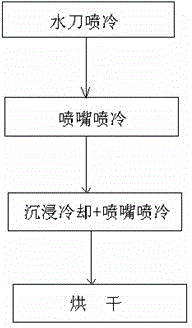

[0041] Such as figure 2 As shown, the slow-cooled strip steel is rapidly water quenched according to the following steps. The cooling water used in this embodiment is chilled water:

[0042] (1) A pair of water jets arranged on both sides of the strip steel are used to spray layered water jets on the surface of the strip steel. The jetting direction of the layered water jets is at an acute angle with the traveling direction of the strip. The cooling water of the water jets The pressure is 30bar;

[0043] (2) Two sets of nozzles arranged on both sides of the strip steel surface are used to spray high-speed water flow on the strip steel surface. The high-speed water flow blows the steam bubbles and vapor film on the strip steel surface away from the strip steel surface, and the high-speed water flow and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com