Microemulsion liquid membrane chemical and treating method thereof applicable to treating heavy metal, ammonia nitrogen and radioactive wastewater

A technology of radioactive wastewater and microemulsion, which is applied in radioactive purification, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of increasing the difficulty of liquid membrane application research and development, affecting the application of liquid membrane treatment technology, etc., to achieve processing speedy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

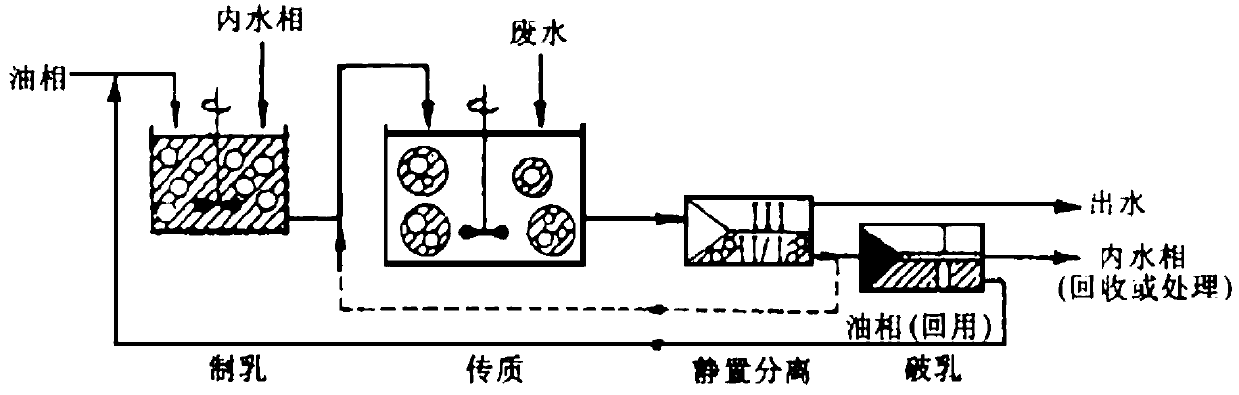

Method used

Image

Examples

Embodiment 1

[0035] A kind of microemulsion membrane medicament that can be used for treating waste water or cleaning polluted soil sample of the present invention, comprises membrane phase and internal water phase, and membrane phase is formulated by the component of following volume fraction:

[0036] Industrial kerosene (or diesel) 42% to 60%,

[0037] Support film agent 3%,

[0038] Carrier substance 6% and

[0039] water balance;

[0040] The volume ratio of the membrane phase and the internal water phase (that is, the commonly referred to as the oil-to-internal ratio) is 1:1 (1: (0.5-2) is acceptable).

[0041] The supporting membrane agent selected in this example is N-butoxypolyoxyethylene polyoxypropylene glycol, N-(1.2-dicarboxyethyl)-N octadecylsulfosuccinamic acid tetrasodium salt, hydroxyethylethylene One of disodium diamine diacetate, octylphenoloxy polyoxyethylene ether alcohol, polyethyleneimine, and polyisopropyleneimine or a combination of any two of them.

[0042] Th...

Embodiment 2

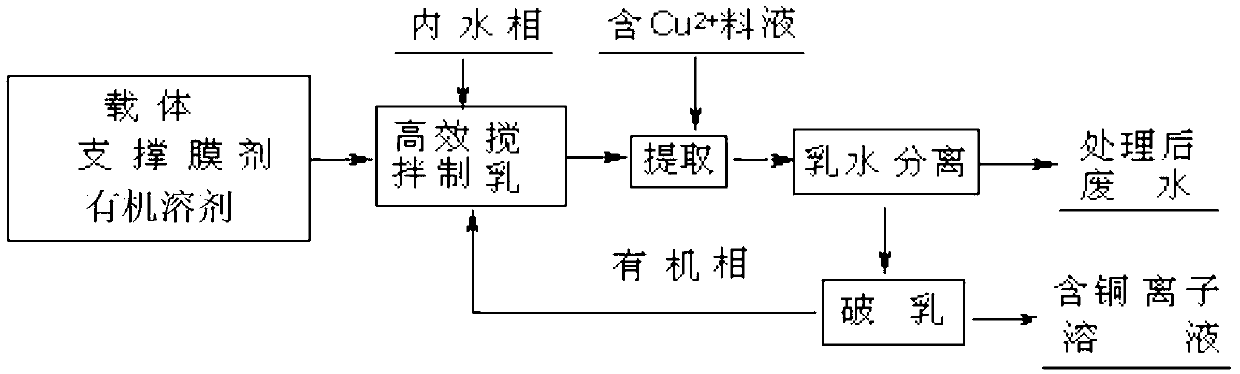

[0044] Embodiment 2: Treatment of copper-containing wastewater.

[0045] A kind of microemulsion membrane medicament that can be used for treating copper-containing wastewater or cleaning polluted soil sample of the present invention, comprises membrane phase and internal water phase, and membrane phase is formulated by the component of following volume fraction:

[0046] Industrial kerosene 60%,

[0047] N-Butoxypolyoxyethylene Polyoxypropylene Glycol 3%,

[0048] Polyethyleneimine 5%,

[0049] 2-Hydroxy-5-nonylsalicylaldoxime (N902) 5% and

[0050] water balance;

[0051] The volume ratio of the membrane phase and the internal water phase (that is, the commonly referred to as the oil-to-internal ratio) is 1:1; the internal water phase selected in this example is 2moI / L H 2 SO 4 .

[0052] a kind of like figure 2 The method that the microemulsion film agent of the present embodiment is used to process the copper-containing wastewater of a pollution control plant may...

Embodiment 3

[0059] Embodiment 3: Treatment of ammonia nitrogen-containing wastewater.

[0060] A microemulsion membrane medicament for treating ammonia nitrogen-containing wastewater of the present invention comprises a membrane phase and an internal water phase, and the membrane phase is formulated from the following components by volume fraction:

[0061] Industrial diesel 60%,

[0062] N-(1.2-Dicarboxyethyl)-N-octadecylsulfosuccinamic acid tetrasodium salt 4%,

[0063] Polyisopropyleneimine 6%,

[0064] Diisooctyl Phosphate (P204) 8% and

[0065] water balance;

[0066] The volume ratio of the membrane phase and the internal water phase (that is, the commonly referred to as the oil-to-internal ratio) is 1:1; the internal water phase selected in this example is 2moI / L H 2 SO 4 .

[0067] A kind of method that uses the microemulsion membrane medicament of the present embodiment to process the method for ammoniacal nitrogen-containing waste water of certain sewage treatment plant,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com