Method for preparing submicron silver powder for electro-conductive paste

A submicron-level, conductive paste technology, applied in the field of conductive paste, can solve the problems of insufficient conductivity of conductive paste, wide distribution range of silver powder particle size, uneven particle size, etc., and achieve low equipment requirements, The effect of narrow distribution range and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of submicron silver powder provided by the invention is divided into two steps:

[0024] The first step is the preparation of nano-silver particles: in the Ag + The concentration is 1×10 -4 mol / L~1×10 -2 In the mol / L silver salt aqueous solution, add the dispersant according to the mass ratio of the dispersant to the silver salt solute in the silver salt aqueous solution of 0.5:1~2:1, and use the cooling device to keep the system temperature at 5~10°C while stirring While adding an aqueous solution of reducing agent with a concentration of 1g / L~10g / L, the amount of reducing agent added is the same as that of Ag in the silver salt aqueous solution. + The molar ratio is 0.1:1~1:1, and the silver particle sol solution of 5~10nm is prepared.

[0025] The second step is the preparation of silver powder: to Ag + The concentration is 5×10 -3 mol / L~5×10 -1 Add the nano-silver particle sol solution prepared in the first step into the mol / L silver s...

Embodiment 1

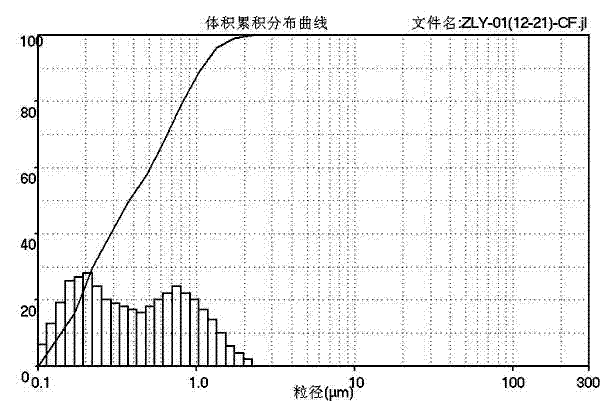

[0028] Preparation of silver powder: Add 50 liters of deionized water into the reaction kettle, dissolve 450 grams of silver nitrate, keep the system temperature at 30°C, weigh 450 grams of ascorbic acid, 3 grams of glycerin and 1.5 grams of polyethylene glycol, and 2 liters of deionized Dissolve in water, keep the temperature at 30°C, slowly add it dropwise into the silver nitrate solution, drop it in about 30 minutes, and stir for another 10 minutes until the reaction is complete. Stop stirring, filter the suspension with suction, wash 5 times with 2 liters of deionized water, then wash 2 times with 500 ml of absolute ethanol, place in a vacuum drying oven, and dry at 70°C for 20 hours to obtain silver powder ,D 50 = 0.37 microns.

Embodiment 2

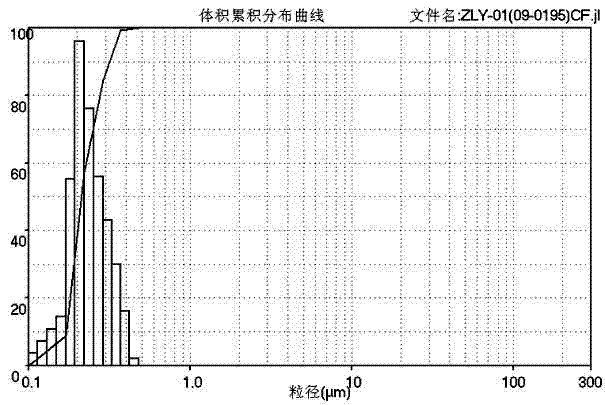

[0030] Preparation of nano-silver particles: Add 5 liters of deionized water into the reaction kettle, dissolve 1.8 grams of silver nitrate, add 1.8 grams of gelatin, dissolve, and cool the system to 5 °C with a cooling device; weigh 0.3 grams of sodium borohydride, dissolve in 100 milliliters of water is also cooled to 5° C., then quickly added to the silver nitrate solution, and stirred until the reaction is complete to obtain a sol solution of silver nanoparticles.

[0031] Preparation of silver powder: Add 50 liters of deionized water into another reaction kettle, dissolve 450 grams of silver nitrate, and add the above nano-silver particle sol solution as seeds during the vigorous stirring process, and keep the temperature of the system at 30°C; 450 grams of ascorbic acid, 3 grams of glycerin and 1.5 grams of polyethylene glycol were dissolved in 2 liters of deionized water, and the temperature was kept at 30°C, and slowly added dropwise to the silver nitrate solution for a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com