System for Young modulus measurement of film

A Young's modulus and thin film technology, which is applied in the field of thin film Young's modulus measurement system, can solve the problems of difficult to apply to the ultra-clean environment of integrated circuits, samples with high porosity, and samples with low reflection coefficients, etc., and achieves the scope of application. Wide, high signal-to-noise ratio, the effect of simplifying the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

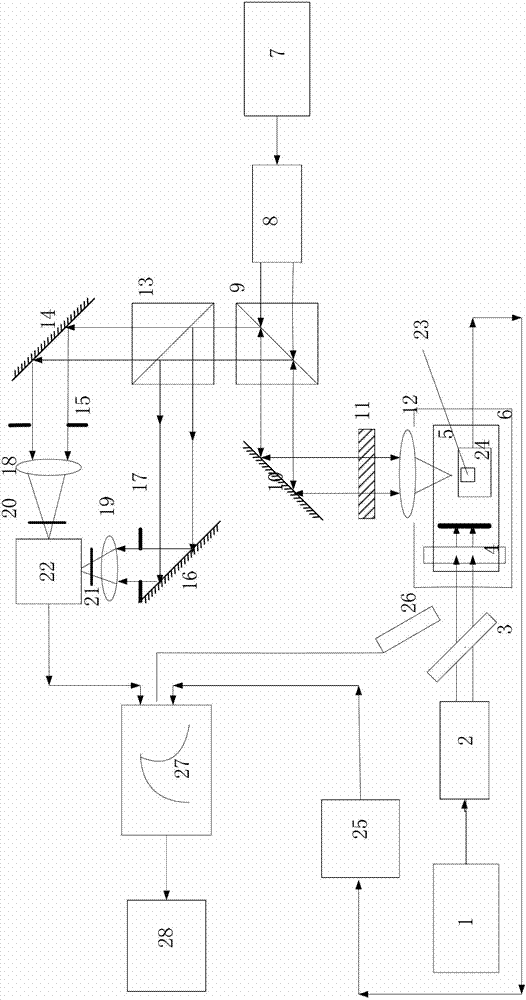

[0052] The working process of PVDF piezoelectric film surface acoustic wave detection through the first detection channel is as follows:

[0053] Pulse laser 1 emits pulse laser, which is collimated and expanded by first beam expander 2, and then divided into two parts by 3:7 beam splitter 3, 7 / 10 pulse laser and 3 / 10 pulse laser, and 7 / 10 pulse laser passes through the cylinder The focusing lens 4 is focused on the surface of the sample 5 to be tested to generate a surface acoustic wave signal; after the PVDF piezoelectric film detector 24 under the piezoelectric probe 23 detects the surface acoustic wave signal, the 3 / 10 pulse laser is used as a trigger signal to trigger the photoelectric The diode 26 outputs the electrical signal to the amplifier 25 via the wire through energy conversion, and the filtered and amplified signal reaches the oscilloscope 27 and finally enters the computer 28 for electrical signal processing.

Embodiment 2

[0055] The workflow of differential confocal SAW detection through the second detection channel is:

[0056] Pulse laser 1 emits pulse laser, which is collimated and expanded by first beam expander 2, and then divided into two parts by 3:7 beam splitter 3, 7 / 10 pulse laser and 3 / 10 pulse laser, and 7 / 10 pulse laser passes through the cylinder The focusing lens 4 focuses on the surface of the tested sample 5 to excite and generate a surface acoustic wave signal; the probe light emitted by the He-Ne laser 7 with a wavelength of 632.8nm is expanded and collimated by the first beam expander 8 and then 1:1 The polarizing beam splitter 910 is polarized so that the transmitted light therein is focused on the surface of the sample 5 to be tested after passing through the first plane reflector 10, the λ / 4 wave plate 11 and the first focusing lens 12, and then press the original path after obtaining the surface acoustic wave return. Due to passing through the λ / 4 wave plate twice, the ...

Embodiment 3

[0058] The working process of detecting PVDF piezoelectric thin film surface acoustic wave and differential confocal surface acoustic wave through the first detection channel and the second detection channel is as follows:

[0059] The first detection channel and the second detection channel should work at the same time. When adjusting, because the second detection channel is more complicated, the second detection channel should be adjusted first according to the actual situation, and then the first detection channel should be adjusted. The electrical signals detected by the first detection channel and the second detection channel can be displayed and stored on the oscilloscope 27 at the same time, and the test situation of the same tested sample 5 by the first detection channel and the second detection channel in the same environment can be visually compared .

[0060] Pulse laser 1 emits pulse laser, which is collimated and expanded by first beam expander 2, and then divided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com