Tip rod adopting chitosan fiber beams as filter materials and preparation method of tip rod

A chitosan fiber and filter material technology, applied in the field of cigarette filters, can solve the problems of affecting the taste and taste, inhalation into the oral cavity, loss of chitosan, etc., so as not to affect the taste and taste, good filtering effect, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

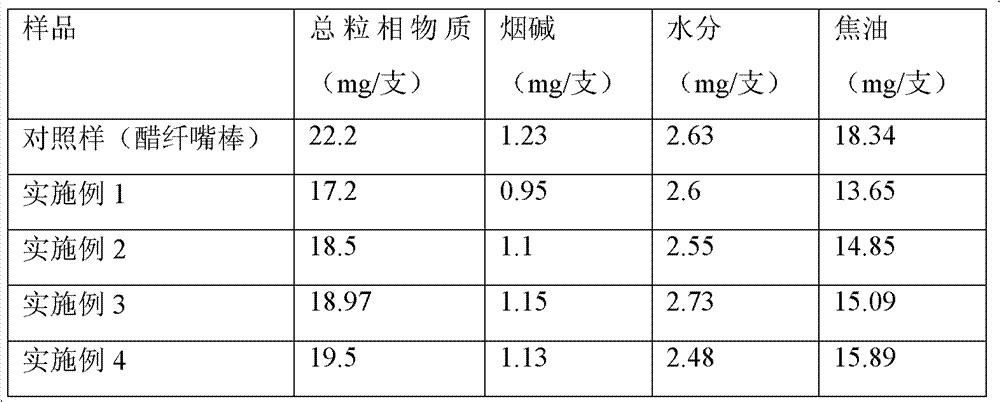

Examples

Embodiment 1

[0016] Choose the molecular weight that is about 200,000 by wet spinning (this is the content of the prior art, the present invention is not limited only to the chitosan fiber prepared by this method, this is only selected by the present embodiment, the same below) The chitosan fiber tow has a linear density of 1.5d, a fiber breaking strength of 1.3cN / dtex, a moisture content of 12%, and a crimp number of 12 / cm. The chitosan fiber bundle is molded on the mouth rod forming machine of the prior art, and the molding speed is controlled at 35 m / min, and 3% glycerin is added as a lubricant, and the three-stage air is opened; the roller pressure is controlled at 1.5MPa, and the roller speed ratio Control between 1:1.3; adjust the grinding angle of the grinding wheel so that the angle of the cutting knife tip is 10 degrees. Spray citric acid aqueous solution accounting for 4% of the total weight of the tow as an adhesive, and the tow after spraying the adhesive is baked at a temperat...

Embodiment 2

[0018] Choose chitosan fibers with a molecular weight of about 600,000 by wet spinning. The linear density of the tow is 3.0d, the breaking strength of the tow is 2.0cN / dtex, the moisture content is 12%, and the number of crimps is 15 / cm. The chitosan fiber tow is formed on a nozzle rod forming machine, the forming speed is controlled at 40 m / min, 2% glycerin is added as a lubricant, and the three-stage air is opened; the roller pressure is controlled at 1.8MPa, and the roller speed ratio is controlled at 1 : 1.8; Adjust the grinding angle of the grinding wheel so that the angle of the cutter tip is 12 degrees. Spray 25% citric acid aqueous solution-glycerin-ethanol mixed solution as an adhesive with a spraying amount of 5% of the total weight of the tow, and bake the tow after spraying the adhesive at a temperature of 120° C. for 10 to 40 minutes. Make the mouth stick with chitosan fiber tow as filter material, in this example, all tow is chitosan fiber tow.

Embodiment 3

[0020] Select chitosan fibers with a molecular weight of about 200,000 through wet spinning. The linear density of the fibers is 1.5d, the breaking strength of the fibers is 2.0cN / dtex, the moisture content is 12%, and the number of crimps is 10 / cm. Form chitosan fiber tow and acetate fiber tow on a concentric round mouth rod forming machine (this forming machine and forming technology are the content of the invention patent that the applicant has applied for and is under examination), and the forming speed is controlled to 40 meters / min, add 2% glycerin as lubricant, three-stage air opening; chitosan fiber tow is the core in the concentric round nozzle rod, and its diameter is 25% of the diameter of the entire nozzle rod. Spray lactic acid aqueous solution-glycerol-ethanol composite adhesive with the spray amount of 8% of tow gross weight, the lactic acid aqueous solution concentration is 50%, makes the mouth bar with chitosan fiber tow as filter material, in this example, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com