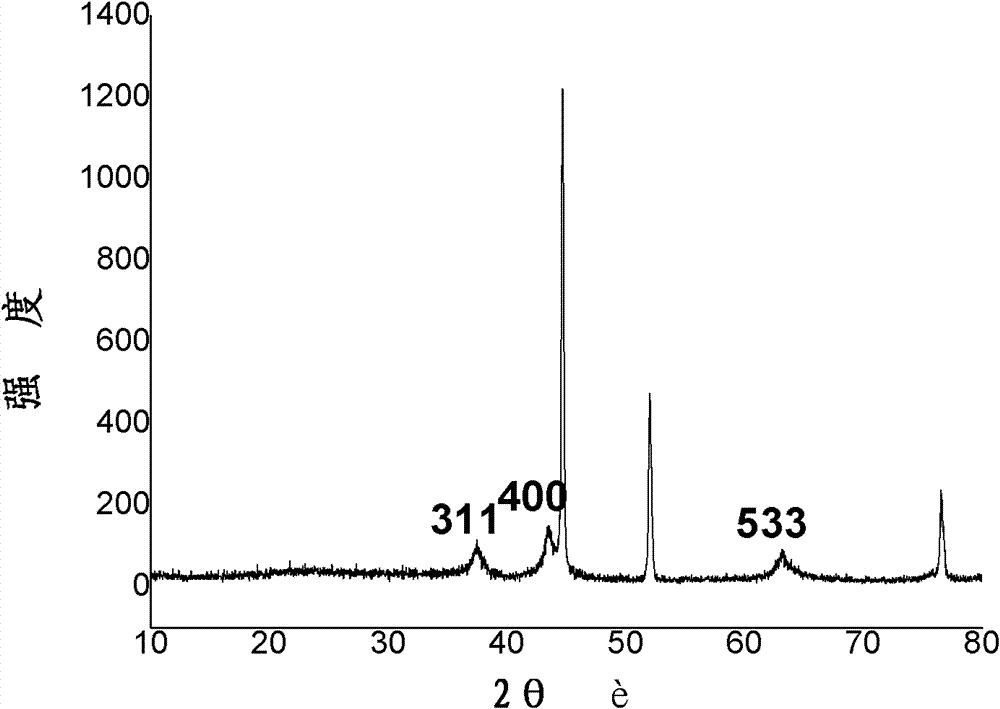

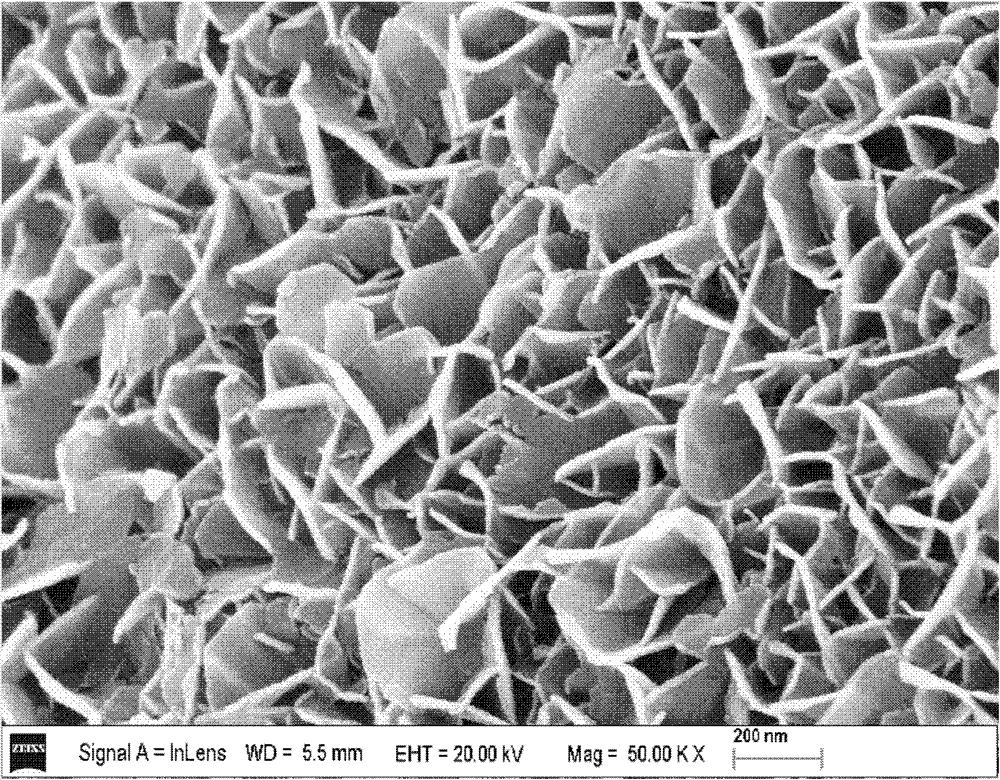

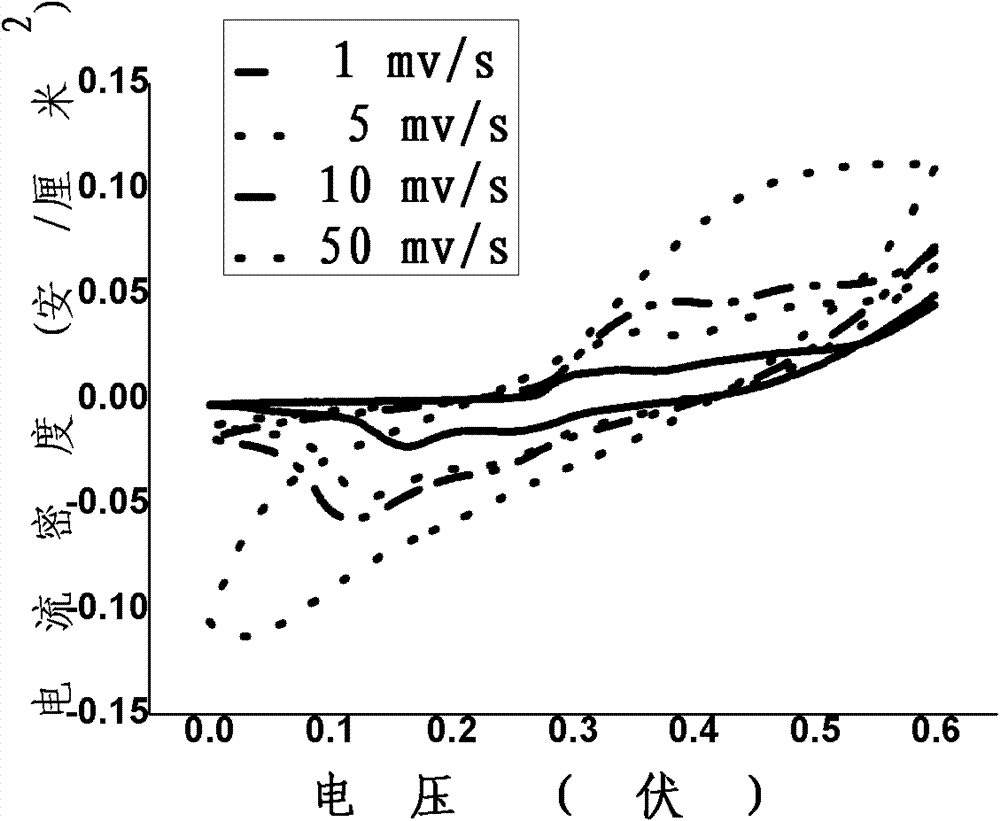

Nickel aluminum composite oxide thin film material and preparation method and applications thereof

A composite oxide and thin film material technology, applied in the field of in-situ growth and preparation of nickel-aluminum composite oxide thin film materials, can solve problems such as limited application, and achieve the effects of not easy to fall off, high adhesion, and complete crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Use nickel foam sheets with a purity greater than 90% as raw materials, cut them into 20*30cm pieces, ultrasonically clean them with 10% hydrochloric acid for 5 minutes, then rinse them with deionized water, put them in an oven at 60°C and dry them for later use.

[0031] Add 64.76g of aluminum isopropoxide to 4L of dilute nitric acid solution with a concentration of 0.05mol / L, stir for 5min, put it into a water bath and heat it to 85°C for 3h under constant temperature reflux, and form a translucent sol after cooling. Centrifuge the sol to remove the precipitate to obtain the aluminum isopropoxide sol; adjust the pH value to about 7.5 with 1% ammonia water.

[0032] Pour the above-mentioned aluminum sol of isopropoxide into a polytetrafluoroethylene reactor, put the treated foamed nickel sheet into an oven at 60°C for 8 hours, take out the reactor, cool it down, take out the nickel sheet, and use it Rinse with ion water, dry, and then bake at 430°C for 3 hours to obtai...

Embodiment 2

[0034] Use nickel foam sheets with a purity greater than 90% as raw materials, cut them into 20*30cm pieces, ultrasonically clean them with 10% hydrochloric acid for 5 minutes, then rinse them with deionized water, put them in an oven at 60°C and dry them for later use.

[0035] Add 50g of aluminum isopropoxide to 4L of dilute nitric acid solution with a concentration of 0.05mol / L, stir for 8 minutes, put it into a water bath and heat it to 90°C for 8 hours, and then form a translucent sol after cooling. The sol was centrifuged to remove the precipitate to obtain the aluminum isopropoxide sol; the pH value was adjusted to 8.0 with 1% ammonia water.

[0036] Pour the above-mentioned aluminum sol of isopropoxide into a polytetrafluoroethylene reactor, put the treated foamed nickel sheet into an oven at 140°C for 36 hours, take out the reactor, cool down, take out the nickel sheet, and use Rinse with ion water, dry, and then bake at 480°C for 4 hours to obtain a nickel-aluminum c...

Embodiment 3

[0038] Use nickel foam sheets with a purity greater than 90% as raw materials, cut them into 20*30cm pieces, ultrasonically clean them with 10% hydrochloric acid for 5 minutes, then rinse them with deionized water, put them in an oven at 60°C and dry them for later use.

[0039] Add 40g of aluminum isopropoxide to 4L of dilute nitric acid solution with a concentration of 0.05mol / L, stir for 10min, put it into a water bath and heat it to 98°C for 12h under constant temperature reflux, and form a translucent sol after cooling. The sol was centrifuged to remove the precipitate to obtain the aluminum isopropoxide sol; the pH value was adjusted to 7.0 with 1% ammonia water.

[0040] Pour the above-mentioned aluminum sol of isopropoxide into a polytetrafluoroethylene reactor, put the treated foamed nickel sheet into an oven at 120°C for 48 hours, take out the reactor, cool down, take out the nickel sheet, and use Rinse with ion water, dry, and then bake at 400°C for 3 hours to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com