Fractal micro channel reactor system for enhancing CO2 absorption, and method thereof

A microchannel reactor and microchannel technology, applied in chemical instruments and methods, separation methods, through absorption, etc., can solve problems such as uneven fluid distribution, uniformity, and reduced absorption efficiency, and achieve enhanced CO2 chemical absorption and operation The process is safe and reliable, and the effect of small instantaneous holding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

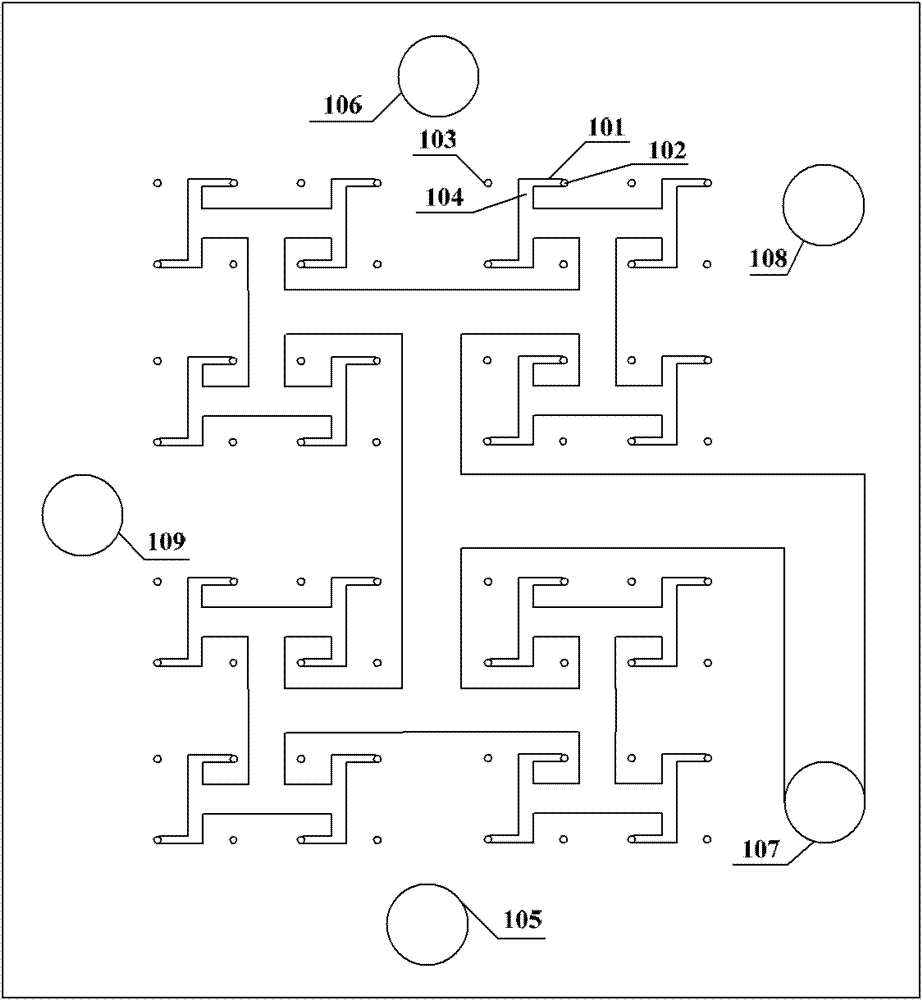

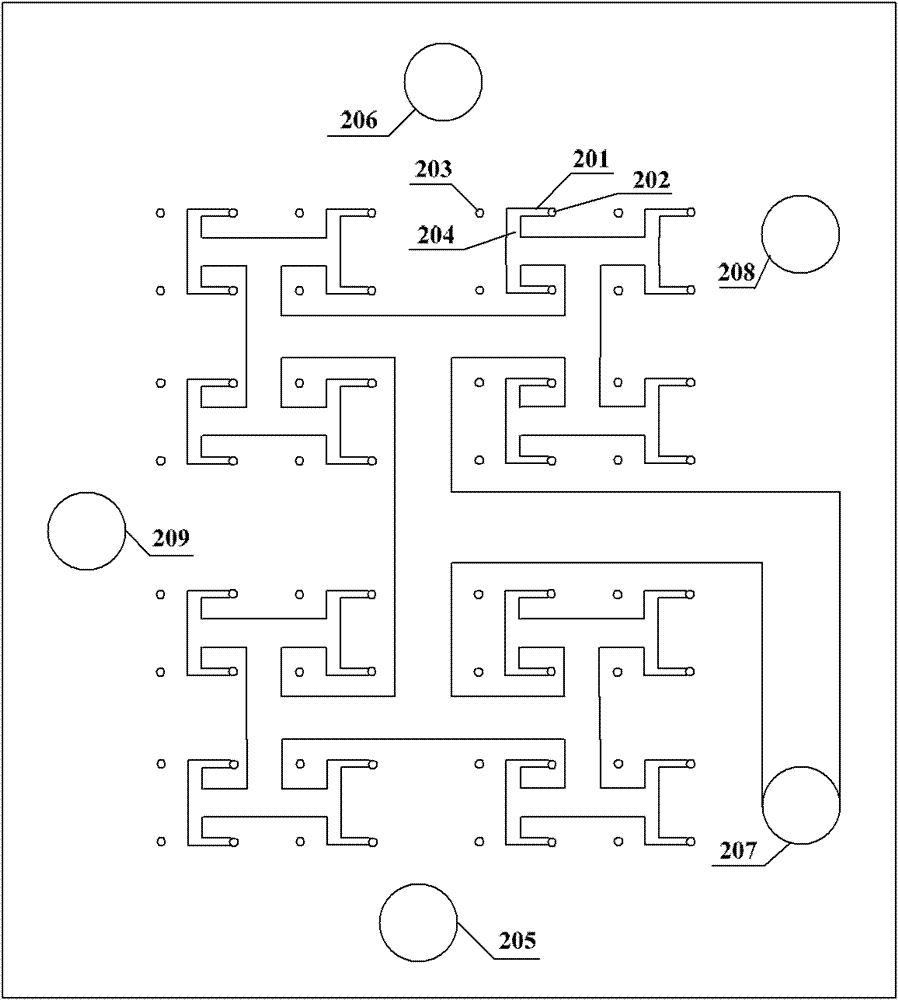

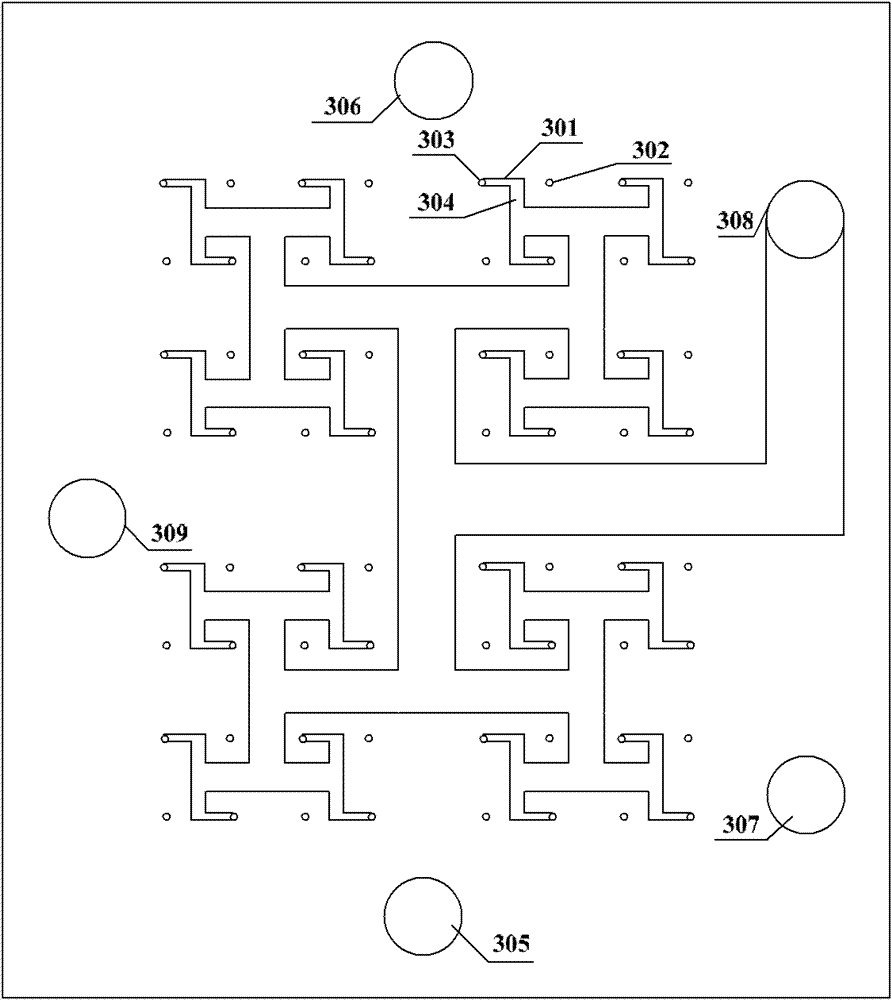

[0040] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention. The present invention is relatively familiar to those skilled in the field of microreactor or microchemical industry: what the present invention relates to is a fractal microchannel absorber, and the characteristic size of the channel is on the order of microns to millimeters; in essence, it relates to gas-liquid in the microchannel Two-phase fluid mixing mass transfer process. The difference is that the present invention provides a new type of microchannel structure, which can achieve a uniform and fine distribution of the two-phase fluid, so as to enhance the mass transfer between the gas-liquid two-phase fluid in the microchannel, especially for CO2-containing fluids....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com