Processing method of lentinan

A processing method and technology of lentinan, which is applied in the field of food processing, can solve the problems of easy corruption and deterioration of the extraction solution, low extraction efficiency, high water polarity, etc., and achieve the effects of shortening the production cycle, high extraction rate, and easy dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

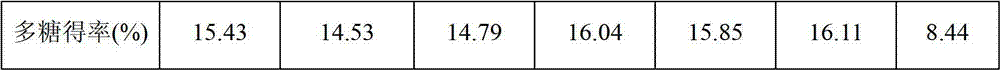

Embodiment 1

[0023] (1) Coarse crushing: Place dried shiitake mushrooms in a crusher for coarse crushing at a speed of 2500r / min for 20min.

[0024] (2) Twin-screw extrusion treatment: The raw mushroom powder with a moisture content of 10% is extruded according to the feed rate of 25kg / h, the extrusion temperature of 120°C, and the extruder speed of 100r / min.

[0025] (3) Semi-biomimetic extraction: Weigh the squeezed mushroom powder, add distilled water at a material-to-liquid ratio of 1:20, adjust the pH of the solution to 4.1 with a disodium hydrogen phosphate-citric acid buffer solution, and perform the first extraction. Then, the pH of the solution was adjusted to 8.4 with disodium hydrogen phosphate-citric acid buffer solution for the second extraction, the extraction temperature was 45° C., and the extraction time was 40 minutes.

[0026] (4) Centrifugation and concentration: Centrifuge the material liquid extracted by the semi-biomimetic method with a centrifuge with a rotation speed of 3...

Embodiment 2

[0029] (1) Coarse crushing: Place dried shiitake mushrooms in a crusher for coarse crushing at a speed of 3000r / min for 15min.

[0030] (2) Twin-screw extrusion treatment: The raw mushroom powder with a moisture content of 15% is extruded according to the feed rate of 30kg / h, the extrusion temperature of 125°C, and the extruder speed of 110r / min.

[0031] (3) Semi-biomimetic extraction: Weigh the extruded shiitake mushroom powder, add distilled water at a material-to-liquid ratio of 1:25, adjust the pH of the solution to 4.2 with disodium hydrogen phosphate-citric acid buffer solution, and perform the first extraction. Then, the pH of the solution was adjusted to 8.5 with disodium hydrogen phosphate-citric acid buffer solution for the second extraction, the extraction temperature was 50° C., and the extraction time was 50 minutes.

[0032] (4) Centrifugation and concentration: Centrifuge the material liquid extracted by the semi-biomimetic method with a centrifuge with a rotating spe...

Embodiment 3

[0035] (1) Coarse crushing: Place dried shiitake mushrooms in a crusher for coarse crushing at a speed of 3000r / min for 15min.

[0036] (2) Twin-screw extrusion treatment: The raw mushroom powder with a water content of 20% is extruded according to a feed rate of 25kg / h, an extrusion temperature of 130°C, and an extruder speed of 120r / min.

[0037] (3) Semi-biomimetic extraction: accurately weigh 500g of the squeezed mushroom powder, add distilled water at a material-to-liquid ratio of 1:30, adjust the pH of the solution to 4.3 with disodium hydrogen phosphate-citric acid buffer solution, and perform the first time After extraction, the pH of the solution was adjusted to 8.6 with the disodium hydrogen phosphate-citric acid buffer solution for the second extraction, the extraction temperature was 60°C, and the extraction time was 55 minutes.

[0038] (4) Centrifugation and concentration: Centrifuge the material liquid extracted by the semi-biomimetic method with a centrifuge with a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com