Pit backfill casting stone made from fly ash, steel slag and coal gangue

A technology of fly ash and coal gangue, applied in the direction of sustainable waste treatment, solid waste management, application, etc., can solve the problems of low utilization rate of valuable components, long production cycle, complicated process, etc., and achieve excellent environmental performance and reduce waste Transportation costs, the effect of abundant materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

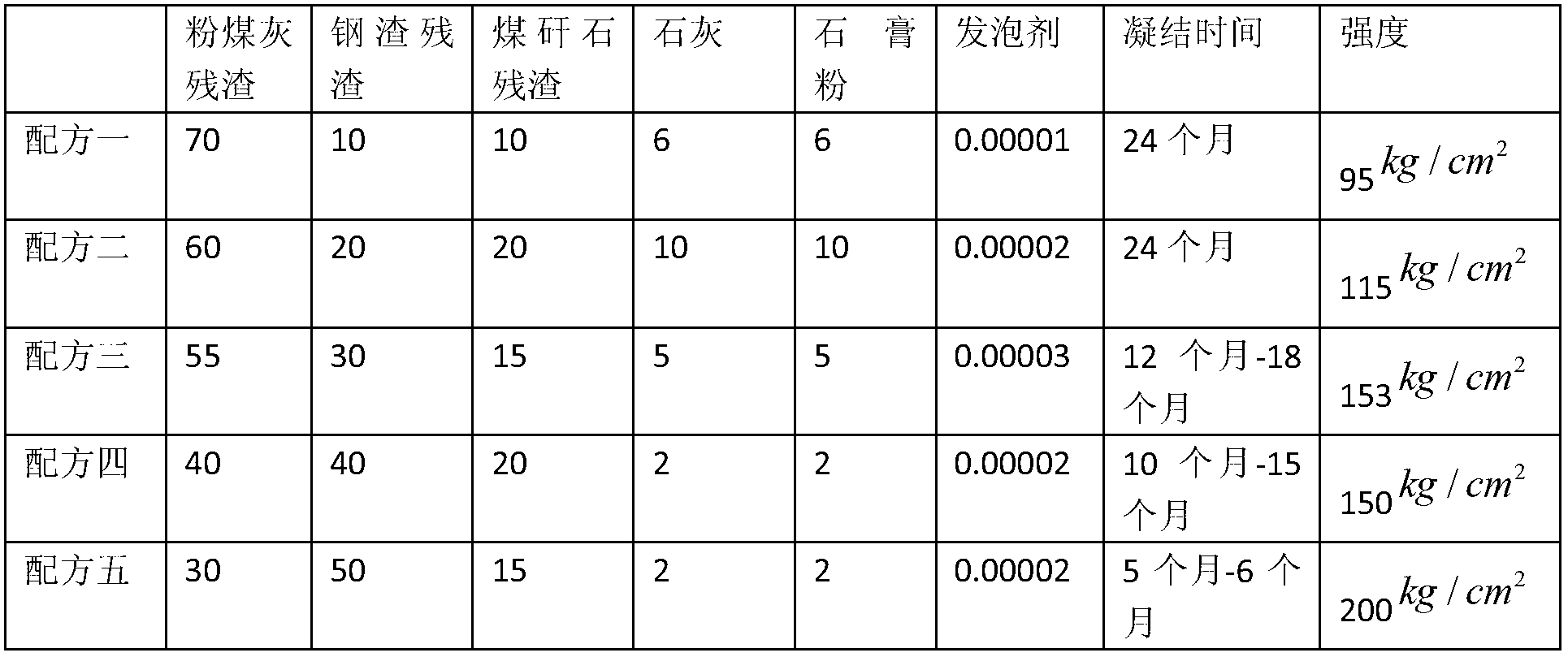

[0024] Embodiment 1 of the present invention. A mine pit backfilling fly ash, steel slag and coal gangue to make pouring stone, which is prepared by adding fly ash, steel slag, coal gangue powder, lime and gypsum powder to a foaming agent, mixing it with water, and pouring it into mines and culverts. Through long-time foaming and coagulation, the coagulation time period is 1 month to 2 years. The foaming agent is concrete foaming agent such as aluminum powder, bicarbonate inorganic salt, tea saponin or rosin soap.

[0025] Embodiment 2 of the present invention. According to different design requirements, by weight components, it consists of 30-70 parts of fly ash, 10-50 parts of steel slag, 10-20 parts of coal gangue powder, 1-10 parts of lime, 1-10 parts of gypsum powder and foaming agent 0.0001-0.0003 parts are prepared. The particle size of each raw material powder is 24 mesh-300 mesh. Mix all the raw material powders with water and pour them into mine caves and culvert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com