Polyglutamic acid macromolecule cross-linking agent containing carbon-carbon double bonds, preparation method and application thereof

A technology of macromolecular cross-linking agent and polyglutamic acid, applied in the field of polyglutamic acid macromolecular cross-linking agent and its preparation, can solve the problems of non-biodegradable, poor water solubility, cost reduction, etc., and achieve simple and easy preparation method Good performance, active reactivity, and wide range of monomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

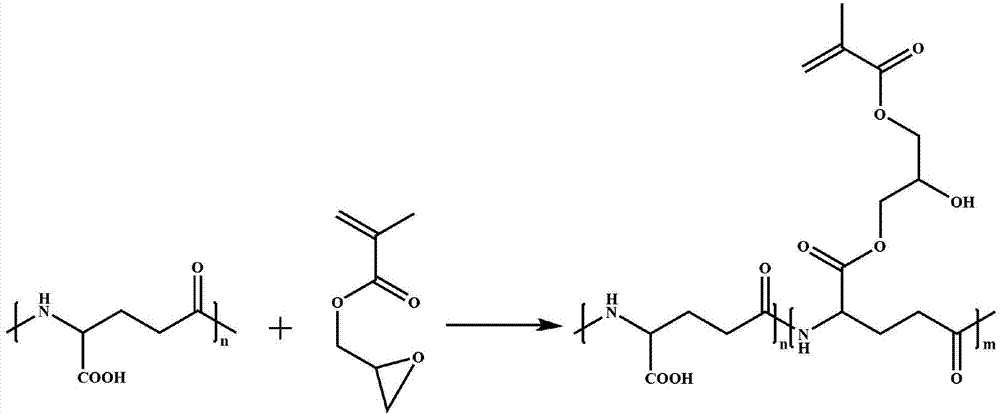

Method used

Image

Examples

Embodiment 1

[0037] (1) Epoxy ring-opening grafting reaction: Dissolve 2g of polyglutamic acid in 98g of distilled water and stir evenly to obtain a polyglutamic acid solution; add 0.2g of glycidyl acrylate to the above polyglutamic acid solution, stir Evenly, to obtain a mixed solution, then add glacial acetic acid to the mixed solution, adjust the pH of the solution to 2, and stir at 20°C for 12 hours to obtain solution A;

[0038] (2) Extraction and cleaning: Add 50ml of dichloromethane whose volume is 0.5 times the volume of solution A into solution A of step (1), stir for 5 minutes, stand for extraction, remove the oil phase after layering, and take the water layer solution; extract 3 times, the resulting aqueous layer solution was combined;

[0039] (3) Freeze-drying: put the aqueous layer solution obtained in step (2) into a freeze dryer, and dry at -5°C until the water is completely removed to obtain a polyglutamic acid macromolecular cross-linking agent;

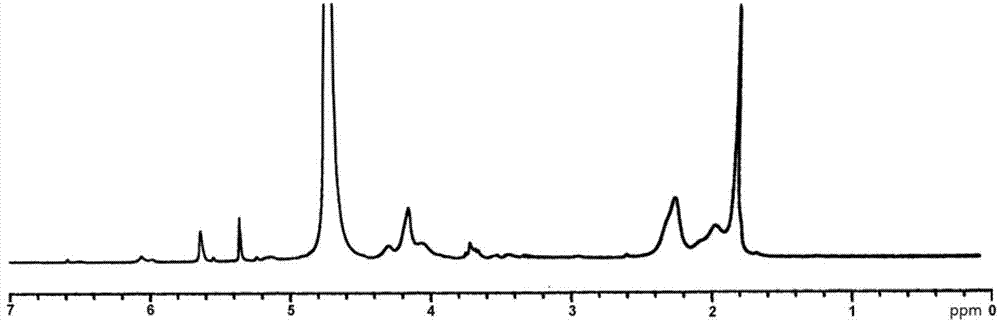

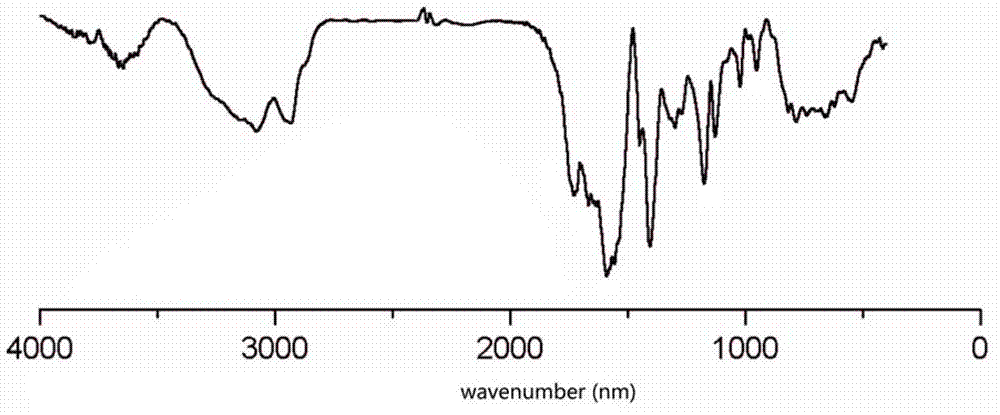

[0040] The polyglutamic...

Embodiment 2

[0044] (1) Epoxy ring-opening grafting reaction: Dissolve 4g polyglutamic acid in 96g water, stir well to obtain polyglutamic acid solution; add 2g glycidyl methacrylate to the above polyglutamic acid solution, stir Evenly, to obtain a mixed solution, then add glacial acetic acid to the mixed solution, adjust the pH of the solution to 2.5, and stir at 25°C for 24 hours to obtain solution A;

[0045] (2) Extraction and cleaning: Add 100ml of ethyl acetate whose volume is 1 times the volume of solution A to the solution A of step (1), stir for 6 minutes, stand for extraction, remove the oil phase after layering, and take the water layer solution; extract 3 times, the resulting aqueous layer solution was combined;

[0046] (3) Freeze-drying: put the aqueous layer solution obtained in step (2) into a freeze dryer, and dry at -20°C until the water is completely removed to obtain a polyglutamic acid macromolecular cross-linking agent;

[0047]The polyglutamic acid macromolecular cr...

Embodiment 3

[0051] (1) Epoxy ring-opening grafting reaction: Dissolve 6g of polyglutamic acid in 94g of water and stir evenly to obtain a polyglutamic acid solution; add 6g of glycidyl methacrylate to the above polyglutamic acid solution, stir Evenly, to obtain a mixed solution, then add glacial acetic acid to the mixed solution, adjust the pH of the solution to 3, and stir at 30°C for 36 hours to obtain solution A;

[0052] (2) Extraction and cleaning: Add 150ml of diethyl ether whose volume is 1.5 times the volume of solution A to solution A of step (1), stir for 7 minutes, stand for extraction, remove the oil phase after layering, and take the water layer solution; extract 4 times, Combine the resulting aqueous solution;

[0053] (3) Freeze-drying: put the aqueous layer solution obtained in step (2) into a freeze dryer, and dry at -40°C until the water is completely removed to obtain a polyglutamic acid macromolecular cross-linking agent;

[0054] The polyglutamic acid macromolecular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com